Glazing robot off-line teaching device and teaching method

An offline teaching and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of poor teaching effect, long teaching cycle, low work efficiency, etc., and achieve simple and convenient programming and high teaching efficiency. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

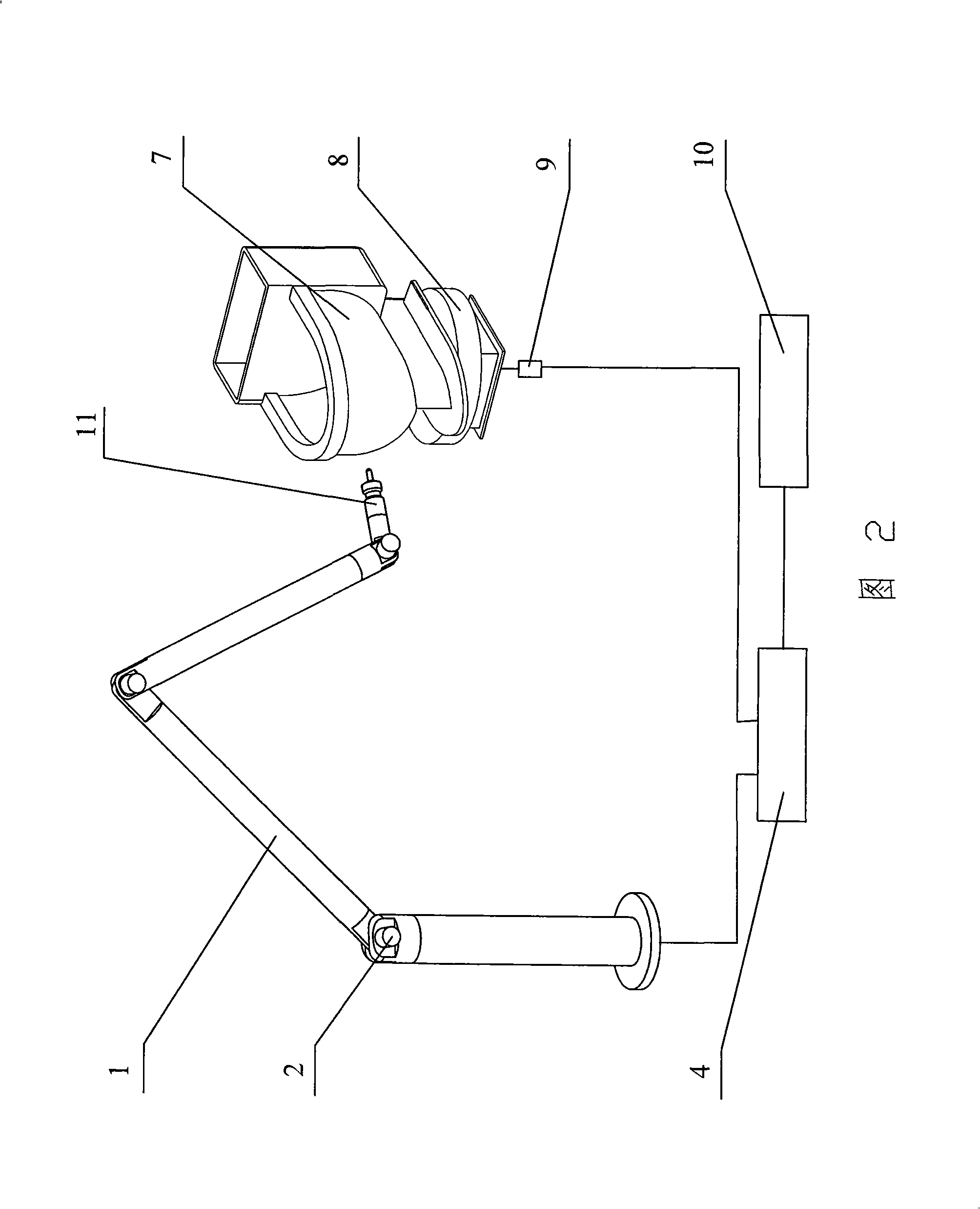

[0026] The invention is composed of a teaching measuring unit, a data collecting unit, a glazing process simulation software, a data downloading unit and the like. Specific examples are as follows:

[0027] Referring to accompanying drawings 1 and 2, the teaching measurement unit is composed of a teaching mechanism 1, a workpiece turntable 9, a workpiece 7, a teaching spray gun 5 and a contact switch 11. Among them, the teaching mechanism 1 is designed and manufactured according to the actual glazing robot, and the teaching mechanism 1 is also used as a workpiece surface measurement mechanism. It has the same degree of freedom, the same hinge type and number, the same mechanism size and the same working space as the glazing robot, but There is no driving motor and reducer for each joint, and only the encoder is used to measure the joint angle.

[0028] The teaching mechanism 1 is composed of six rotating joints, and each joint is connected by a light-weight connecting rod wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com