Exhaust gas recirculation valve and cooler combined test device

An exhaust gas recirculation valve and exhaust gas recirculation technology are applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., which can solve problems such as lack of core technologies, avoid repeated disassembly and assembly, reduce the number of valves, install and test and The effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

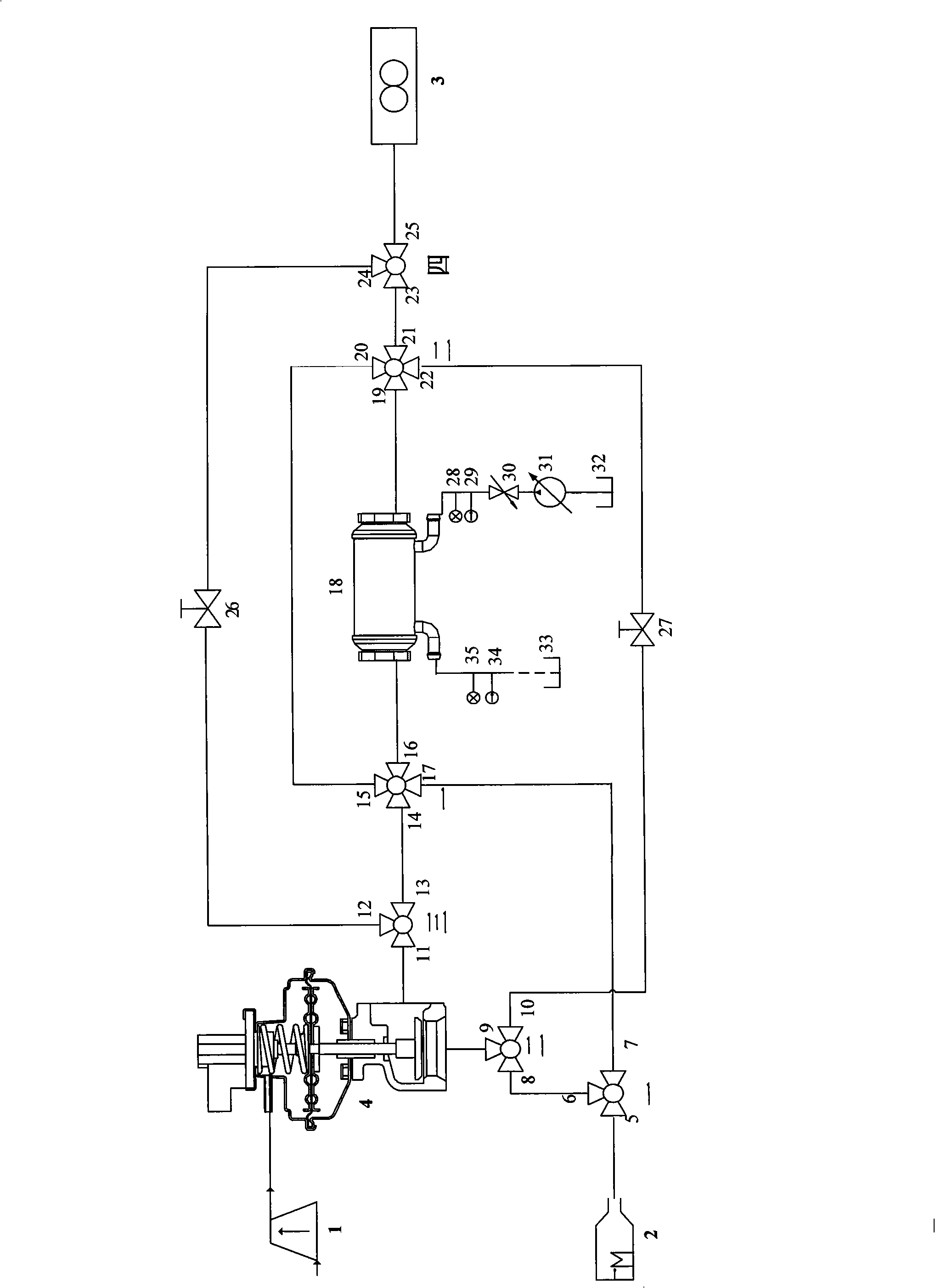

[0021] Such as figure 1 As shown, the outlet of the vacuum degree generating and adjusting device 1 in the exhaust gas recirculation valve and cooler combined test device is connected to the vacuum inlet of the exhaust gas recirculation valve 4 to be tested, and the inlet 5 of the first three-way valve is connected to the high-temperature exhaust gas The outlets of the generating and regulating device 2 are connected, the first outlet 6 of the first three-way valve is connected to the first inlet 8 of the second three-way valve, and the outlet 9 of the second three-way valve is connected to the inlet of the exhaust gas recirculation valve 4 to be tested. The outlet of the exhaust gas recirculation valve 4 is connected to the inlet 11 of the third three-way valve, the second outlet 13 of the third three-way valve is connected to the first inlet 14 of the first four-way valve, and the second outlet 16 of the first four-way valve is connected to The inlet of the exhaust gas recir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com