Stretching assembly of elevator apparatus

A technology of stretching components and elevators, which is applied to elevators, textile cables, transportation and packaging in buildings, etc., and can solve problems such as increased complexity of system layout, loud car noise, and meshing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

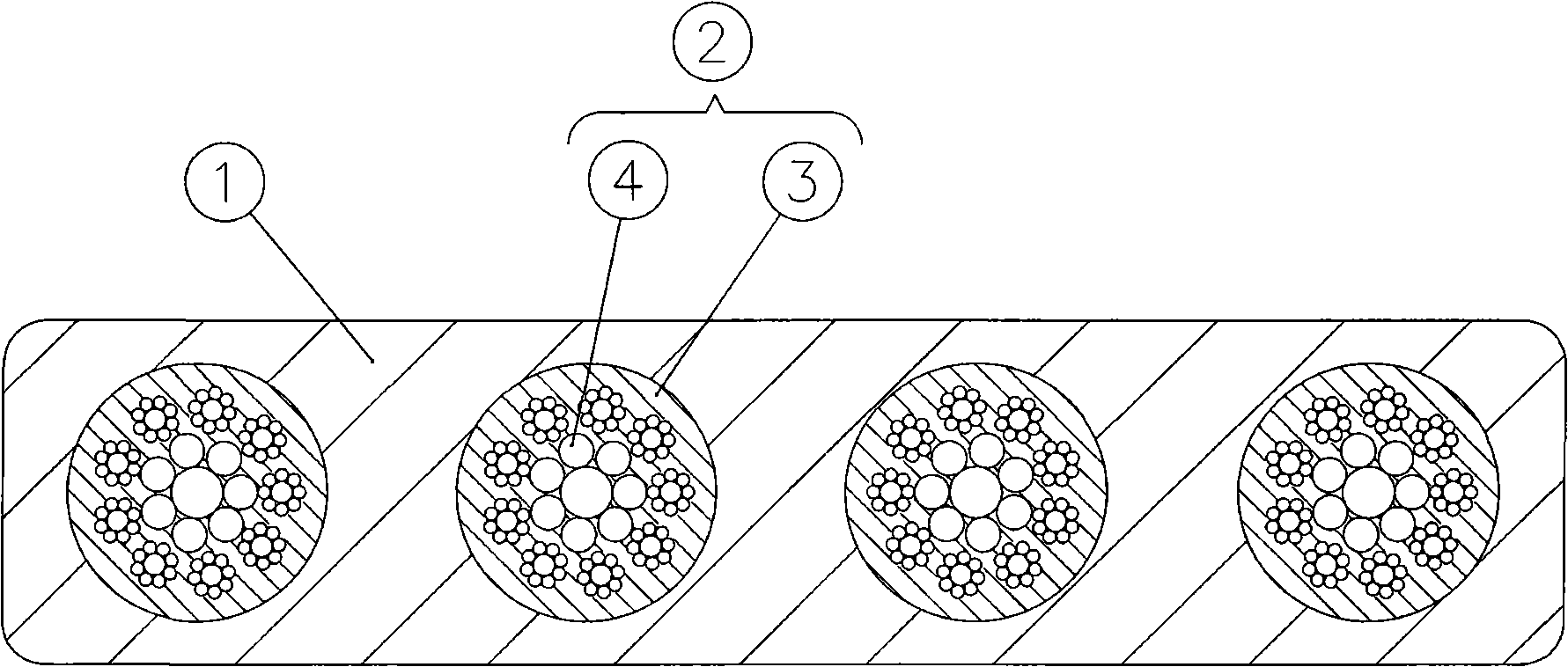

[0020] see figure 1 As shown, the tensile assembly includes a wrapping body 1 and a carrier body 2 , and the carrier body 2 is composed of a coating layer 3 and a carrier core wire 4 . There are 9 strands on the periphery of the load-bearing core wire 4 . In the center of the load-bearing core wire 4 there is a strand. Each strand of the carrying core wire 4 is formed by parallel twisting of a plurality of metal core wires. In this way, the contact between the metal core wires of each strand is a line contact, so the contact stress between the metal core wires is reduced. At the same time, the carrying core wire 4 can maintain a good shape. In order to improve the bending fatigue strength of the load-bearing core wire 4, the metal core wire is required to be relatively thin, about 0.15-0.6 mm. In addition, in order to further increase the bending fatigue life of the load-bearing core wire 4 , the ratio of the diameter of the load-bearing core wire 4 to the diameter of the ...

Embodiment 2

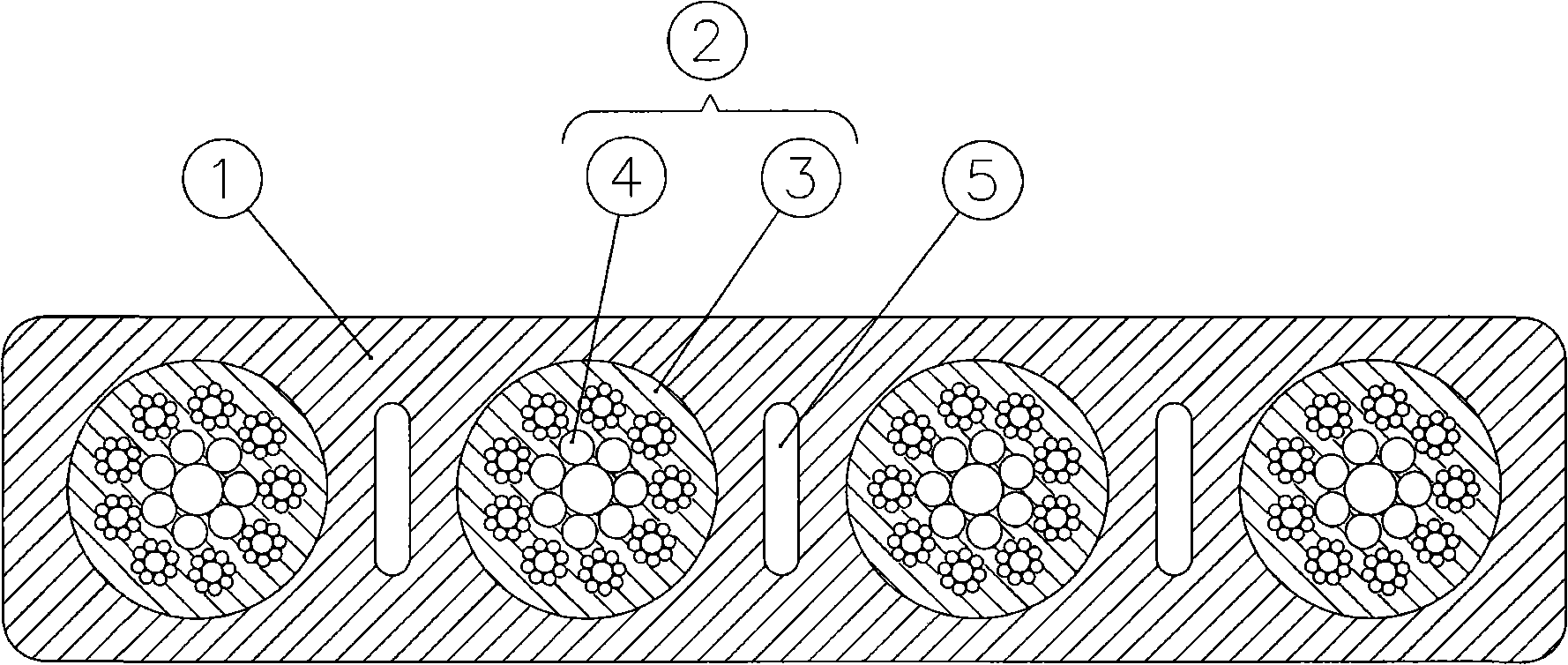

[0030] see figure 2 As shown, the difference from the first embodiment is that three holes 5 are provided in this embodiment. Holes 5 are located between adjacent carriers 2 . The effect of the hole 5 is that the arrangement between the stretching assembly and the traction pulley and the anti-sheave does not necessarily have to be parallel. Because the hole 5 can eliminate the internal stress on the inclusion 1 when the stretching assembly is not parallel to the arrangement of the traction sheave and the anti-sheave. Thus does not affect the life of the tensile components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com