Articulated multiple-shaft drive bidirectional driving electric motor coach

A multi-axis drive and two-way driving technology, which is applied to steering mechanisms, steering rods, vehicle components, etc., can solve problems such as large safety hazards, inconvenient U-turns, and complex structures, and achieve vibration reduction, energy saving, and stable transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

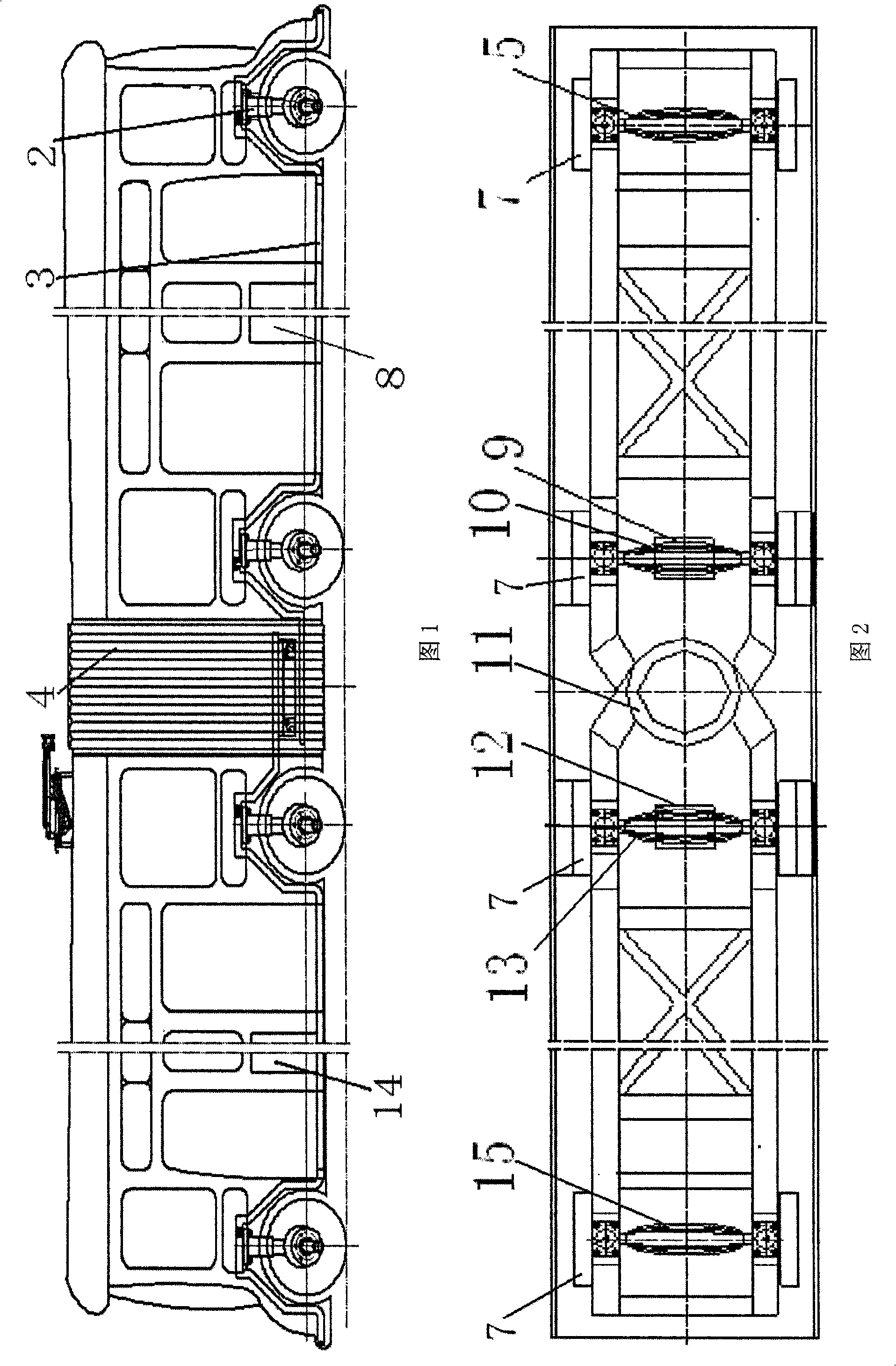

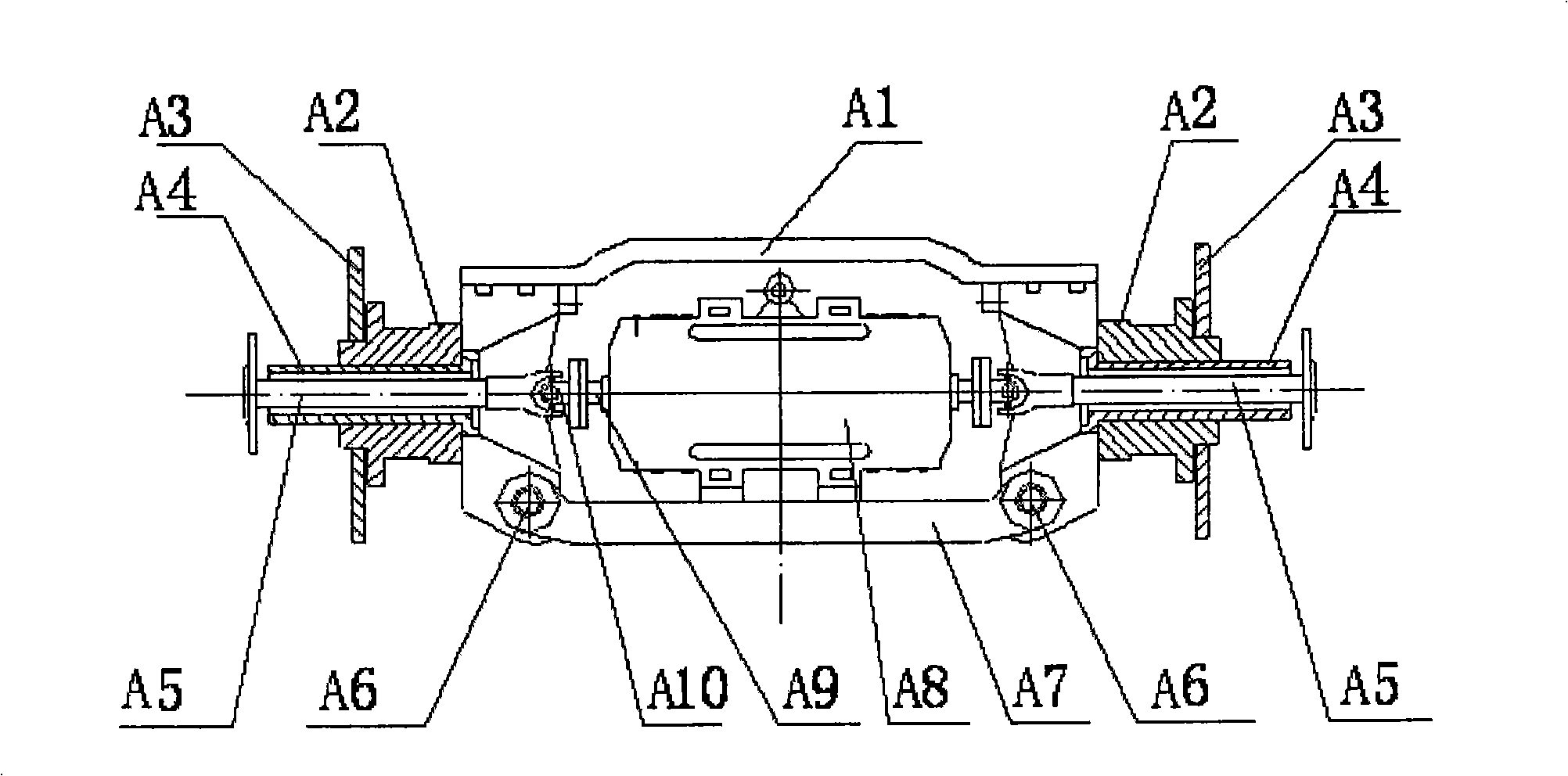

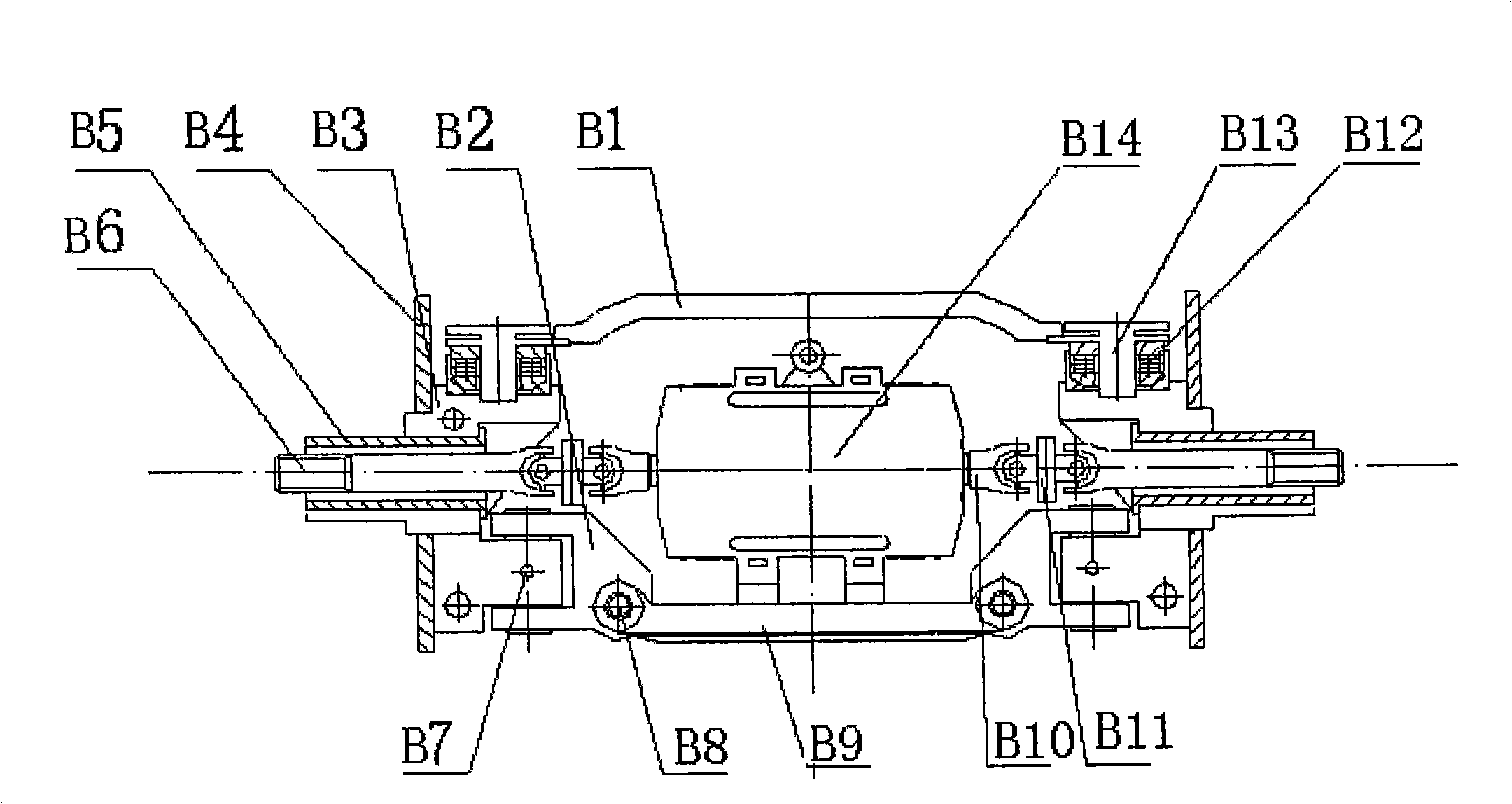

[0019] The articulated multi-axis drive two-way driving electric passenger car of the present embodiment refers to Fig. Steering axles 5, 15 and two front and rear cabs are provided with control devices, differential drive axles 10, 13 are located in the middle of the car body, and the middle of differential drive axles 10, 13 passes through the first differential motor 9 and the second differential drive axle respectively. The differential motor 12 supplies the torque to the wheels 7 at both ends, and the two bridges are hinged together through the passenger car passage turntable 11. The high-speed drive steering axles 5 and 15 are respectively arranged on the front and rear sides of the car body, and the on-board energy sources (capacitors, batteries, etc.) are placed inside the capacitor compartments 8 and 14 installed on both sides of the whole car body. The two ends of the axle of the steering axle are respectively provided with shock absorbing springs (or airbags) 2 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com