Multifunction tiller

A cultivator and multi-functional technology, applied in the field of ditch clearing, intertillage cultivator, and ridging, it can solve the problems of unsatisfactory operation effect, high labor intensity, and large change of moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

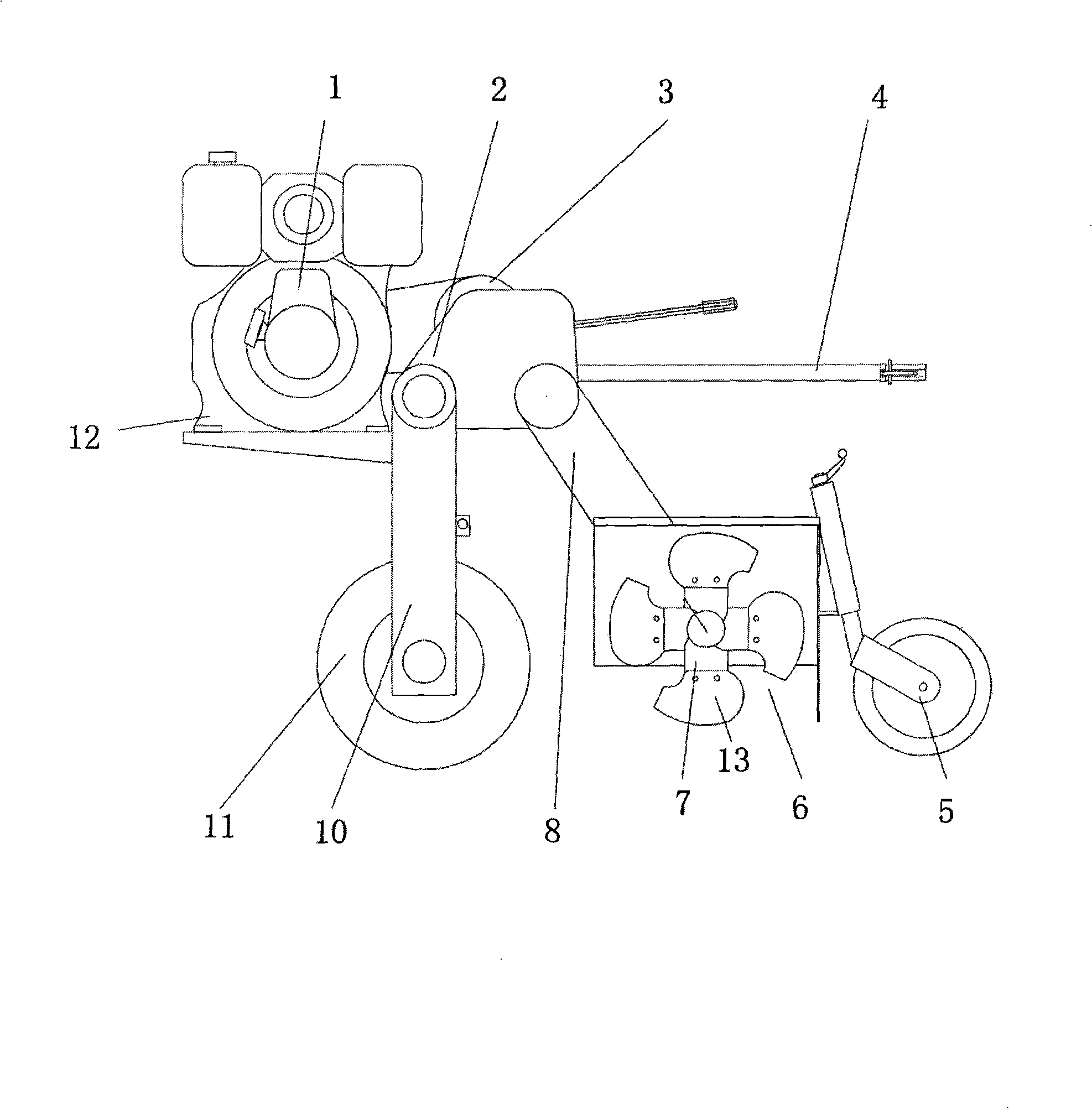

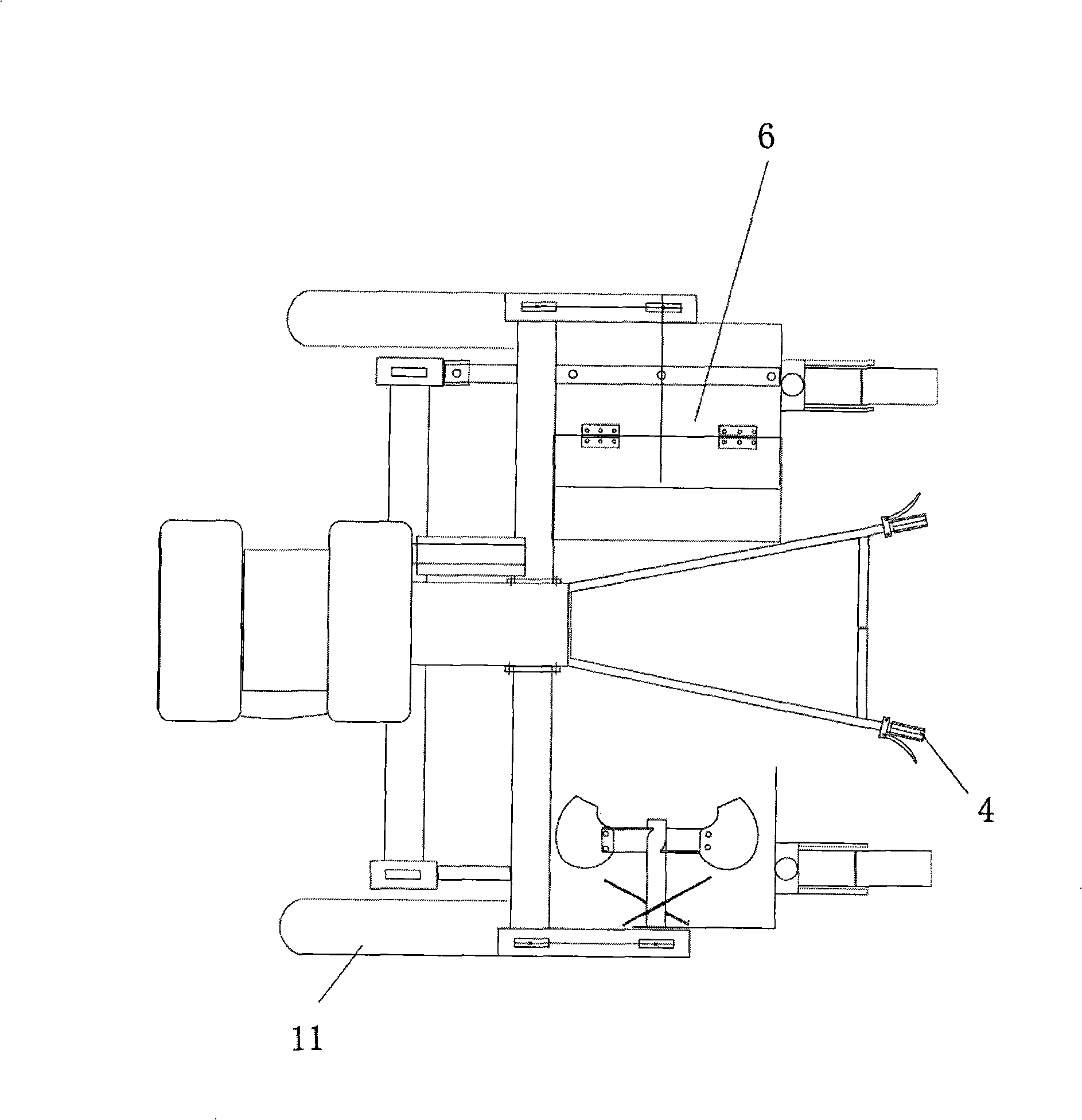

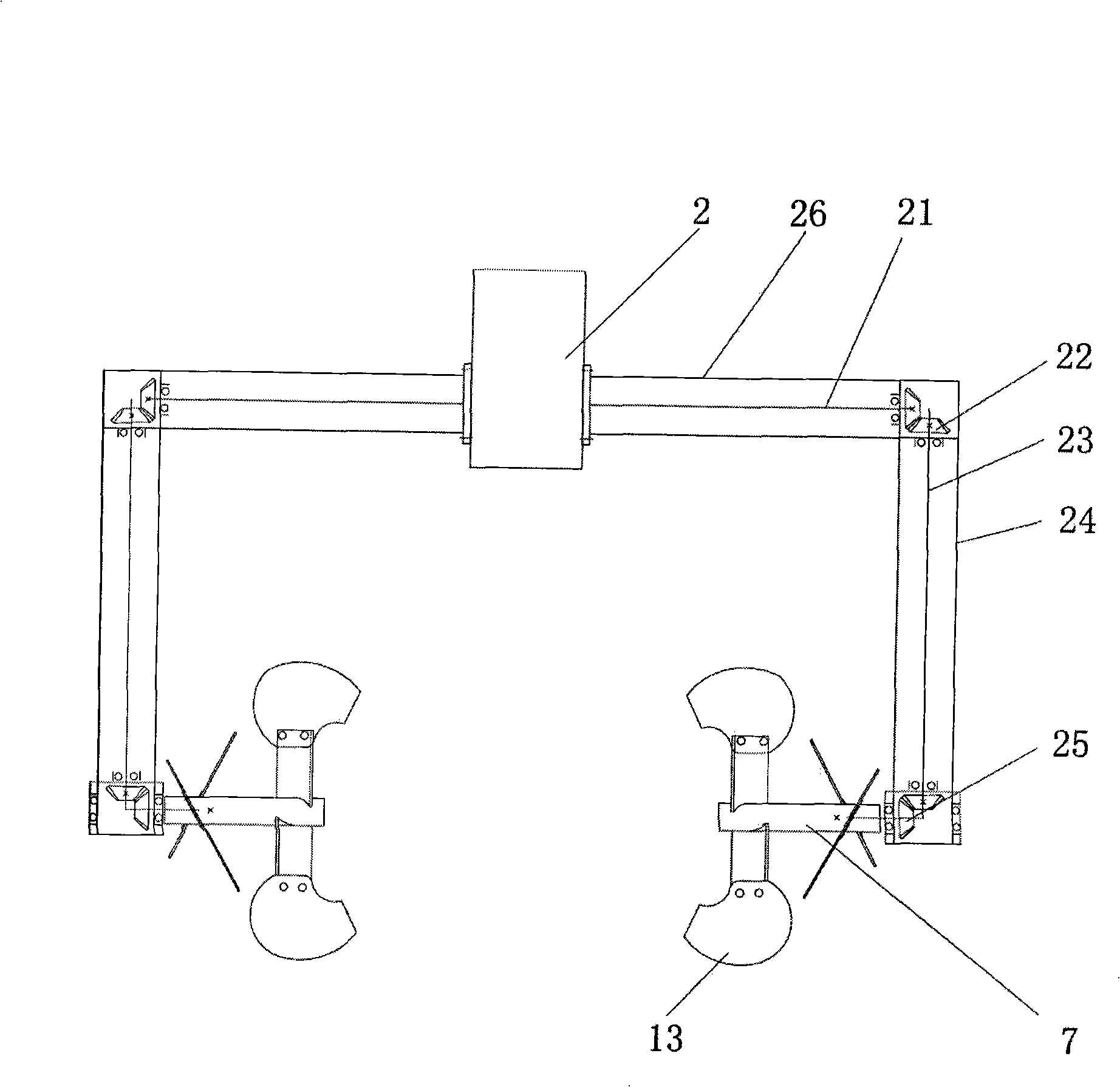

[0039] see figure 1 and figure 2 A multifunctional cultivator, comprising a fuselage 12, an engine 1, a gearbox 2, an armrest frame 4, a coulter 13 and a soil guide scraper 6, the engine 1 is fixed in front of the fuselage 12, and the engine 1 is connected to the gearbox 2 , the gearbox 2 is provided with a clutch 3, the armrest frame 4 is connected with the gearbox 2, and the gearbox respectively drives the coulter transmission mechanism 8 and the driving wheel transmission mechanism 10, and the coulter transmission mechanism 8 drives the coulter 13, and the coulter transmission mechanism 8 drives the coulter 13, and the coulter The knife is two independent coulters, which are respectively located on both sides of the fuselage; the driving wheel transmission mechanism 10 drives the driving wheel 11; the end of the coulter transmission mechanism is provided with a soil guide scraper 6, and the soil guide scraper is fixed on the On the rotor side, the coulter transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com