Multi-use power module

A power module and multi-purpose technology, which is applied in the direction of output power conversion devices, electrical components, electric solid-state devices, etc., can solve the problems of increasing management and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

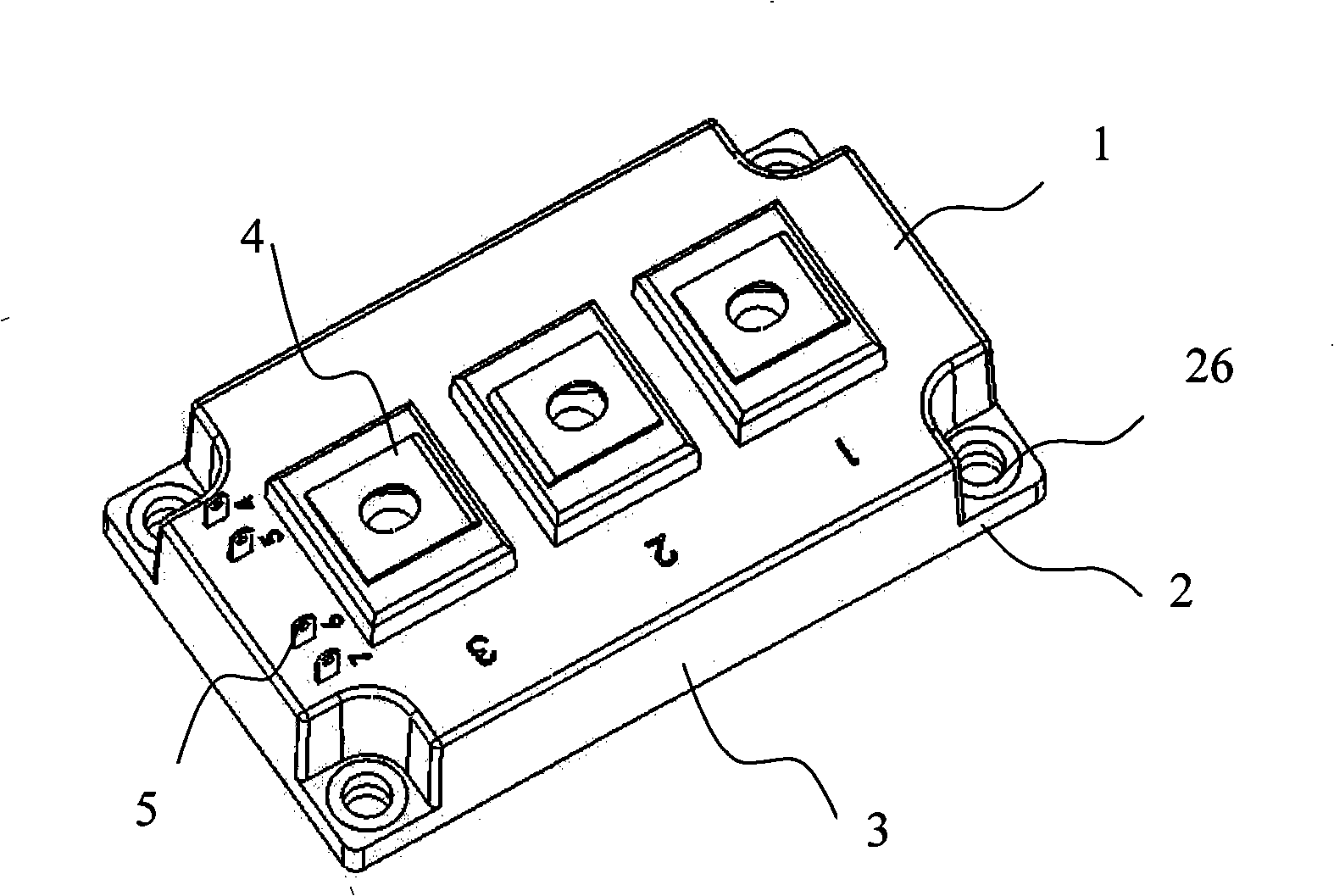

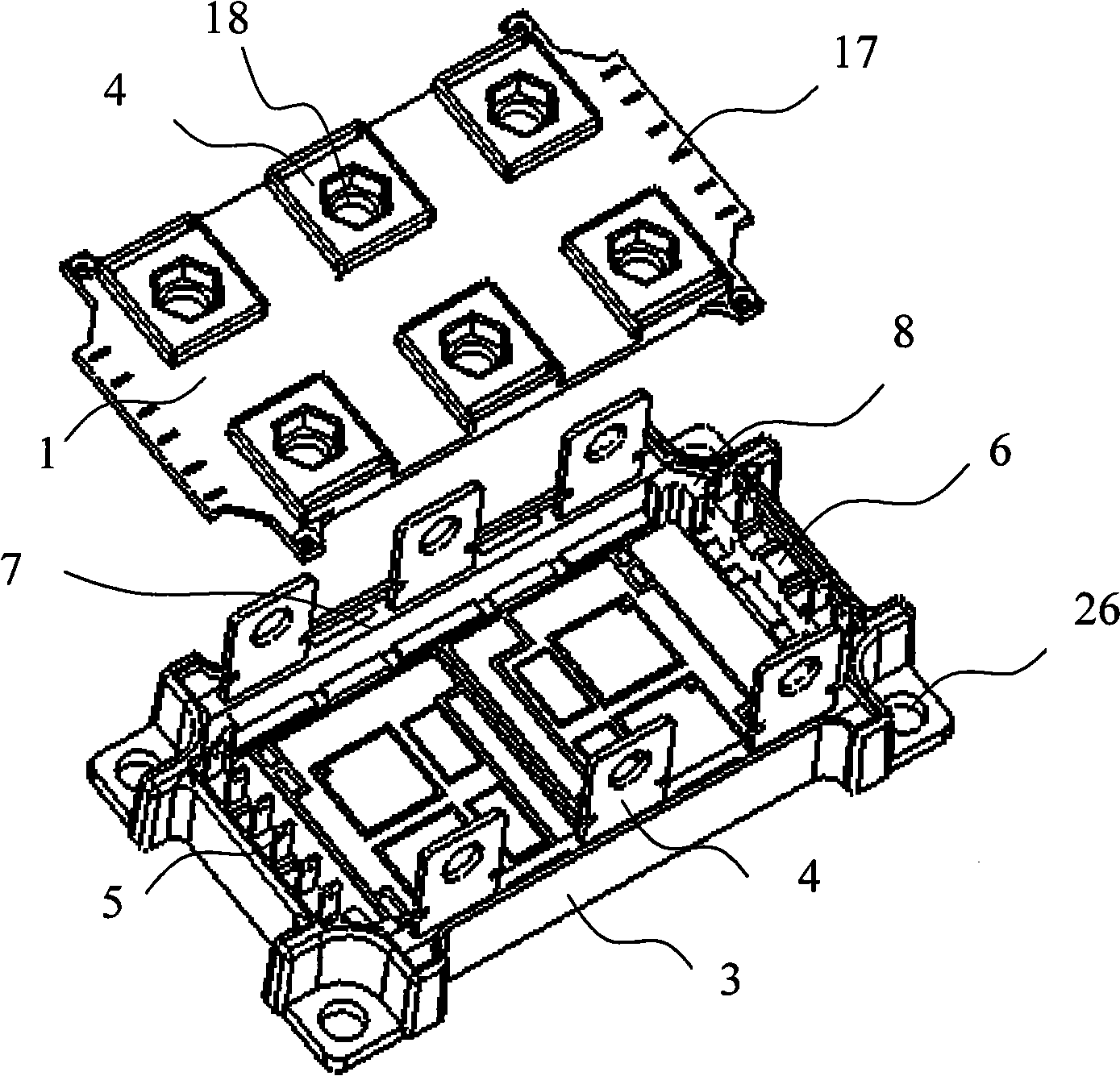

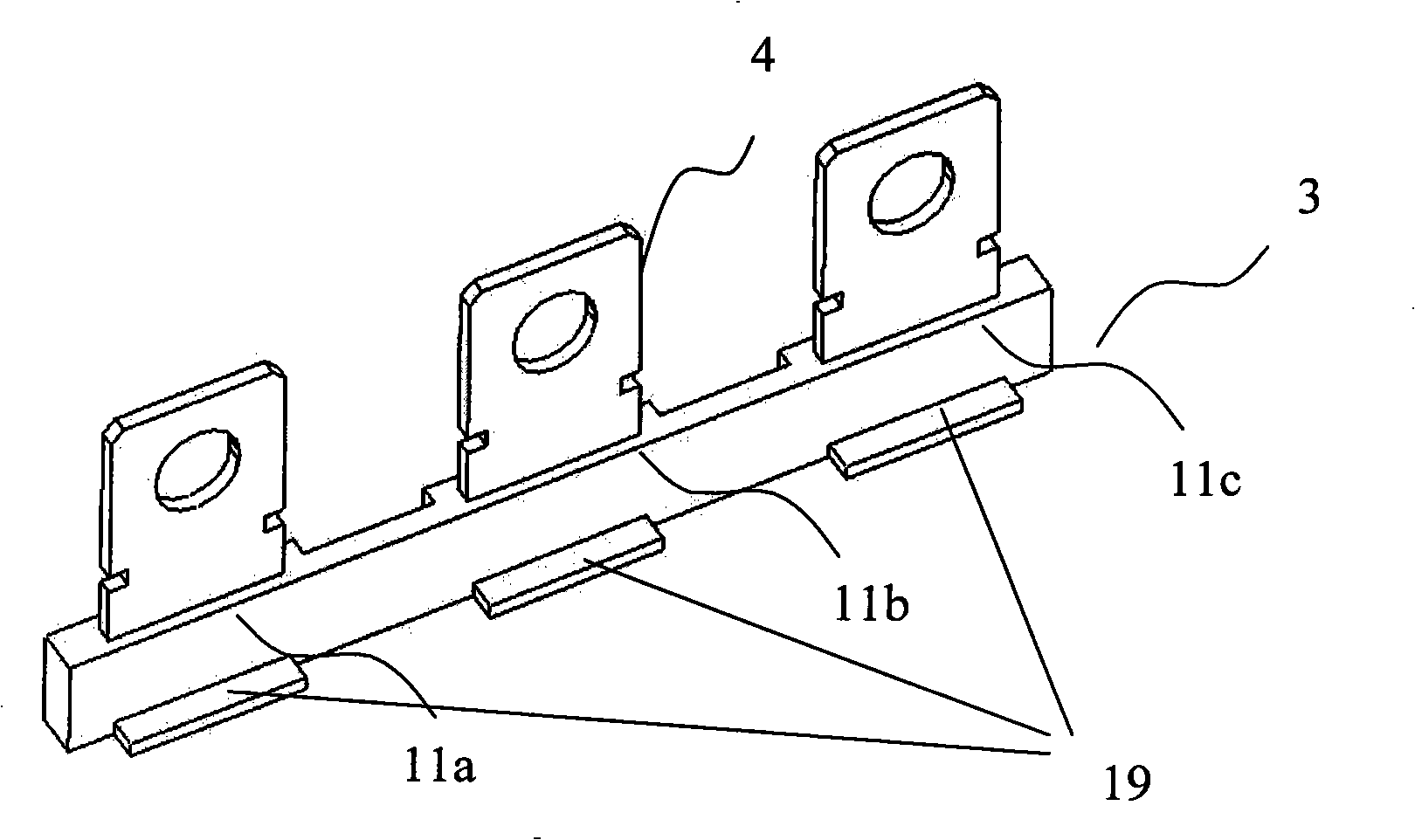

[0025] like figure 2 As shown, the multi-purpose power module 100 includes a top cover 1 , a bottom plate 2 , a frame 3 , a power terminal 4 and a signal terminal 5 , a power terminal support 7 and a signal terminal support 6 . The four corners of the bottom plate 2 are provided with mounting and positioning holes 26, and the bottom plate is provided with a DBC substrate and a chip. There are stoppers 8 at the four corners of the frame 3 , two power terminal brackets 7 are respectively embedded in the space between the front and rear sides of the frame 3 and the stoppers 8 , and the two signal terminal brackets 6 are respectively embedded in the left and right sides of the frame 3 and space between stops 8. Three power terminal holes 18 are respectively provided on the front and rear sides of the top cover 1 , and the distance between two adjacent power terminal holes 18 is equal, and six signal terminal holes 17 are respectively provided on the left and right sides of the t...

Embodiment 2

[0030] In this embodiment, the power module is used as a three-phase full bridge plus a chopper structure, such as Figure 7 As shown, a first power terminal 41a, a second power terminal 42a, and a third power terminal 43a are respectively provided in the first to third power terminal jacks on the first power terminal bracket located in the front of the frame 3, which are respectively used as The DC+, DC- and chopper power terminals are drawn out and installed on the power terminal holes 18 on the top cover 1 respectively. A first power terminal 41b, a second power terminal 42b, and a third power terminal 43b are respectively provided in the first to third power terminal jacks on the second power terminal bracket located in the rear of the frame 3, which are respectively U, V , W output power terminals are drawn out and installed on the power terminal holes 18 on the top cover 1 respectively. A total of seven groups of signal terminals 5 are arranged on the first signal termi...

Embodiment 3

[0032] In this embodiment, the power module is constructed as a half bridge or a chopper. like Figure 8 As shown, a first power terminal 41a, a second power terminal 42a, and a third power terminal 43a are respectively provided in the first to third power terminal jacks on the first power terminal bracket located in the front of the frame 3, which are respectively used as The U, V, W output power terminals are drawn out and installed on the power terminal holes 18 on the top cover 1 respectively. Two groups of five signal terminals 5 are arranged on the first signal terminal bracket and the second signal terminal bracket in the left and right sides of the frame 3. They are drawn out through the signal terminal holes 17 on the top cover and distributed on the left and right sides of the module. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com