Single card oil layer blasting hole plugging column

A technology for plugging pipes and oil layers, applied in the field of pipe strings, can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

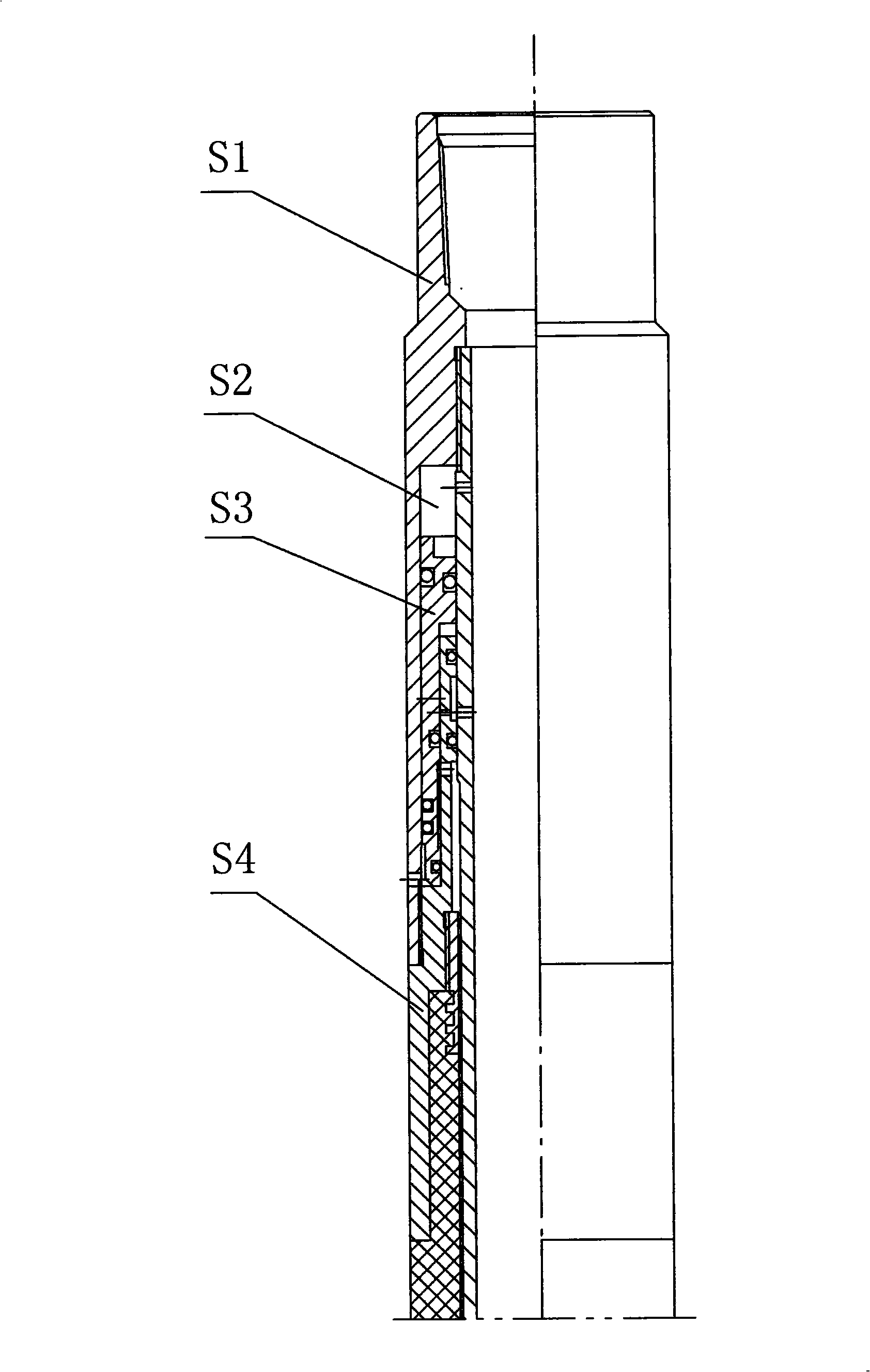

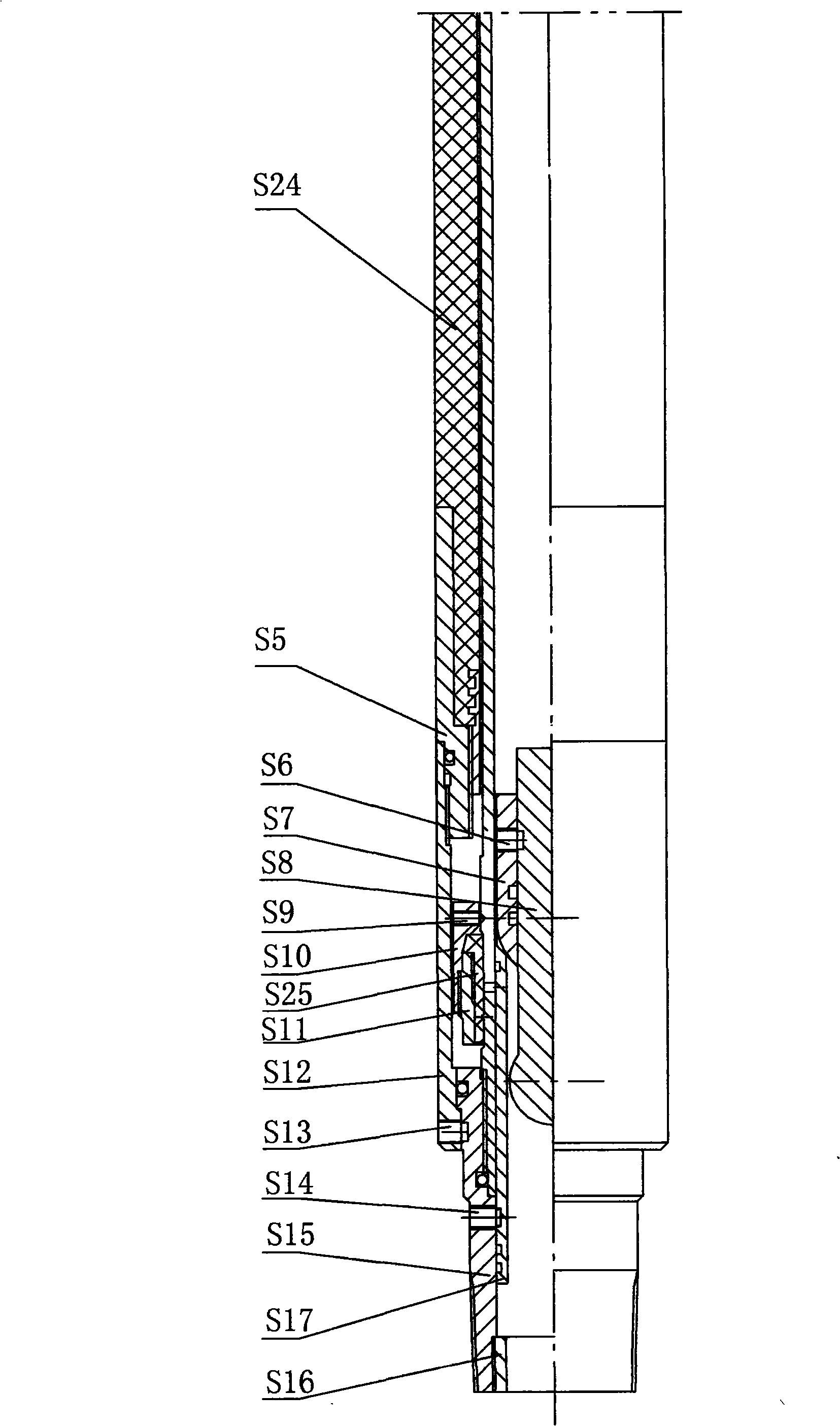

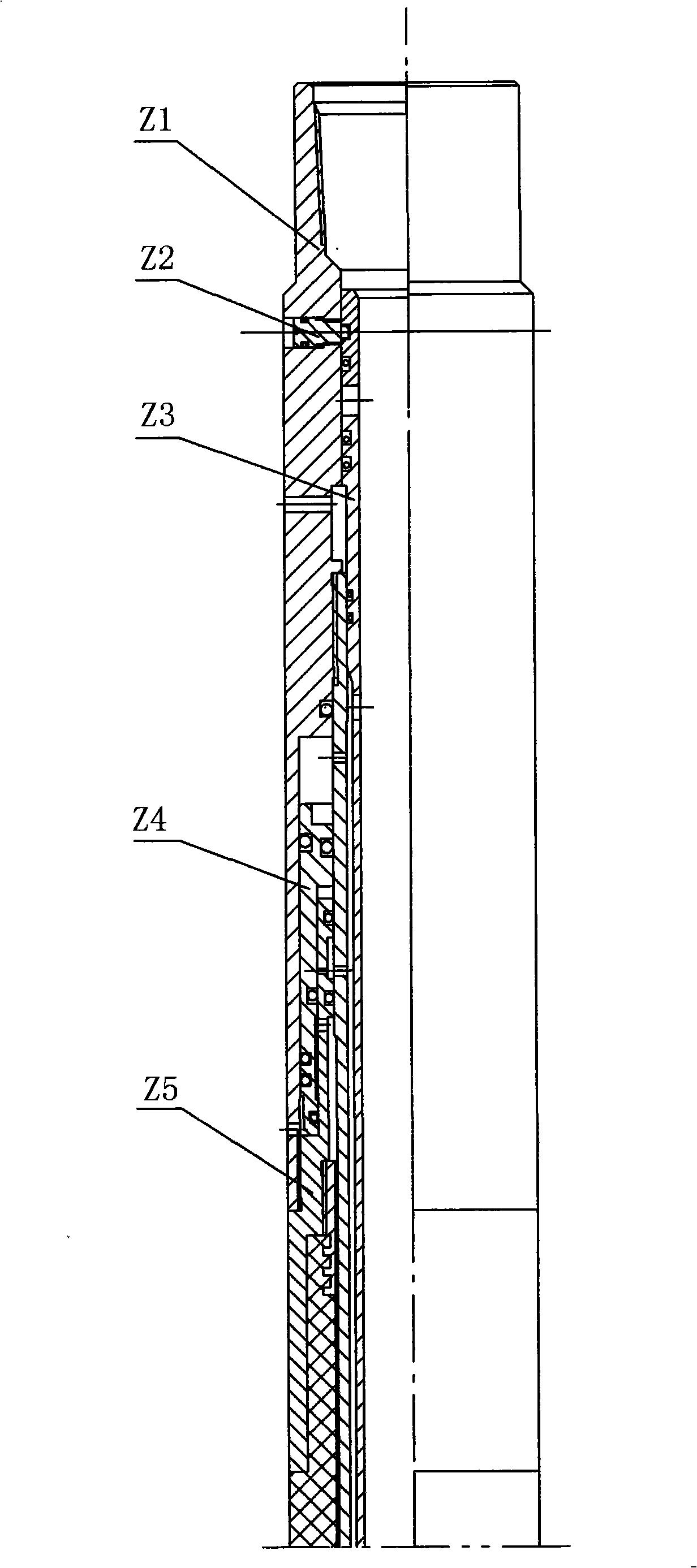

[0020] This type of single-stuck oil layer blasthole plugging string includes an upper-level packer, an intermediate-level packer and a lower-level packer connected by oil pipes, among which such as figure 1 combine figure 2 As shown, the upper packer is composed of the upper sealing joint S1, the upper sealing center pipe S2, the upper sealing well cleaning and unsealing piston S3, the upper sealing rubber sleeve sleeve S4, the upper sealing rubber sleeve S24, the upper sealing lower rubber sleeve Sleeve S5, upper seal pin S6, upper seal Hou Ning superior ball S7, upper seal Hou Ning intermediate ball S8, upper cover bowl upper sheath S10, upper cover one-way leather bowl S25, upper cover bowl lower sheath S11, upper seal The lower jacket S12, the upper seal pull-off pin S13, the upper seal Hou Ning pin S14, the upper seal lower joint S15, the upper seal limit gear S16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com