Load bearing spring of vibration rotary frame for discharging tin of ceramic mould

A ceramic mold and rotating frame technology, applied in the field of load-bearing springs, can solve the problems of inconvenient installation and demolition, no comparison documents are found, etc., and achieve the effect of convenient installation and demolition and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

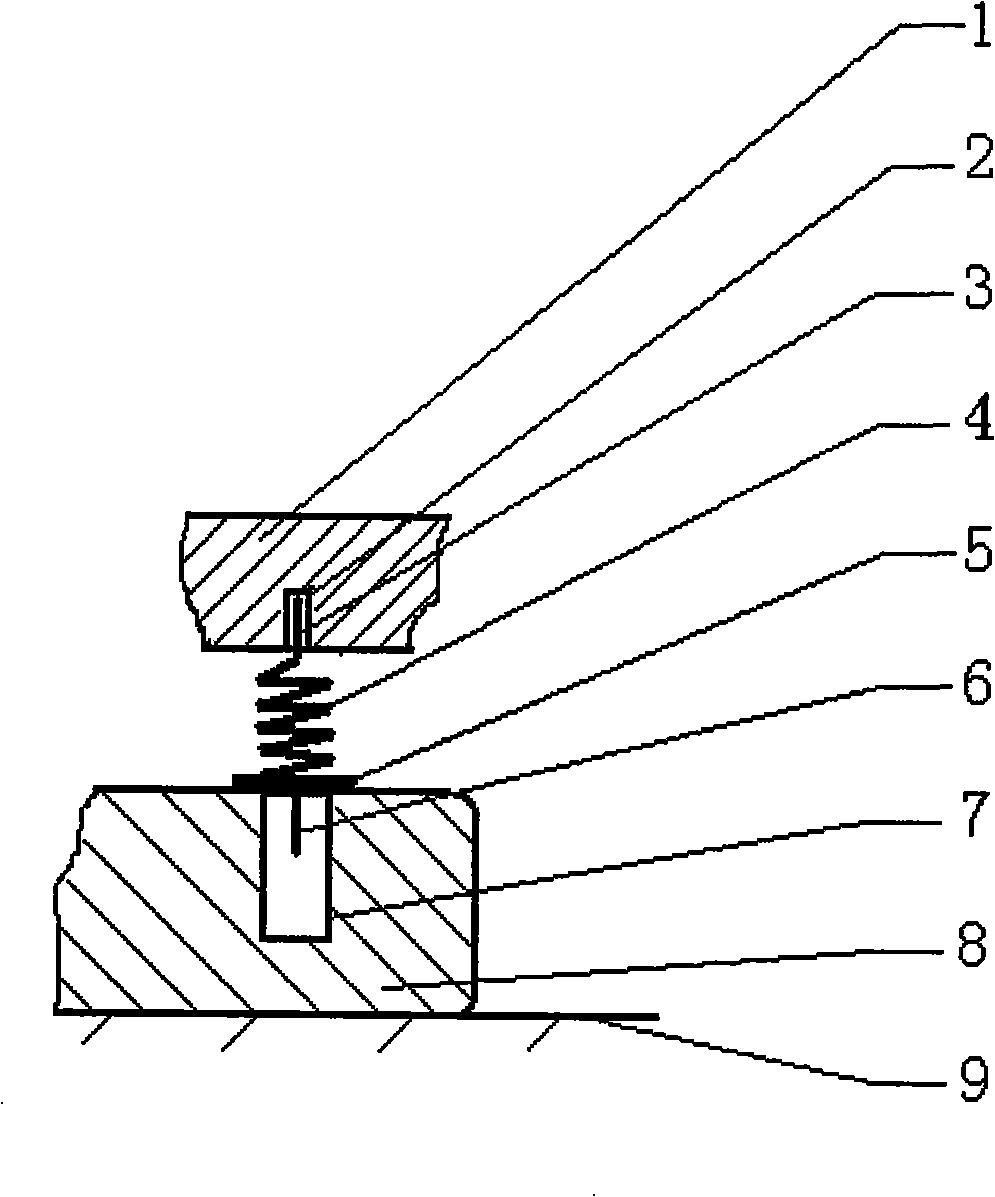

[0010] The vibrating rotary frame for ceramic mold tin discharge provided by the present invention has multiple load-bearing springs, including a spring body 4, a threaded connecting rod 3, a seat ring 5, and a positioning rod 6, wherein the vibratory rotary frame for ceramic mold tin discharge includes a base 1 and base plate 8; threaded hole 2 is arranged on base 1; positioning hole 7 is arranged on base plate 8, is fixed on the ground 9; threaded connecting rod 3 is fixed on the upper end of spring body 4 and is connected with spring body 4 as a whole; The lower end of the spring body 4 is connected as a whole with the spring body 4, and its aperture is greater than the aperture of the positioning hole 7; the positioning rod 6 is fixed at the center of the seat ring 5 and is connected as a whole with the seat ring 5, and is paid out downwards. In addition, the method of fixing the base plate 8 on the ground 9 includes cement seat fixing and screw fixing, which is common sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com