Method for synthesizing high-specific surface area nano-lanthanum ferrous acid with mesoporous silicon dioxide as mould plate

A technology of mesoporous silica and high specific surface area, applied in chemical instruments and methods, iron compounds, rare earth metal compounds, etc., can solve the problem of low specific surface area of lanthanum ferrite, and achieve low cost, catalytic and adsorption performance The effect of improvement and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

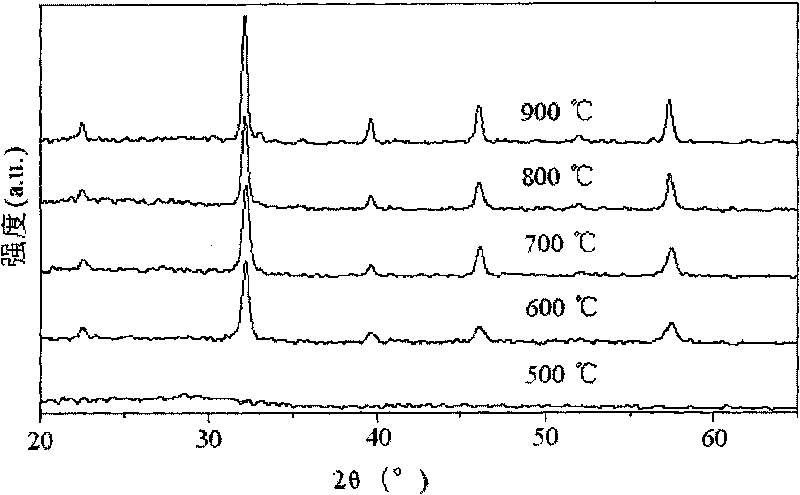

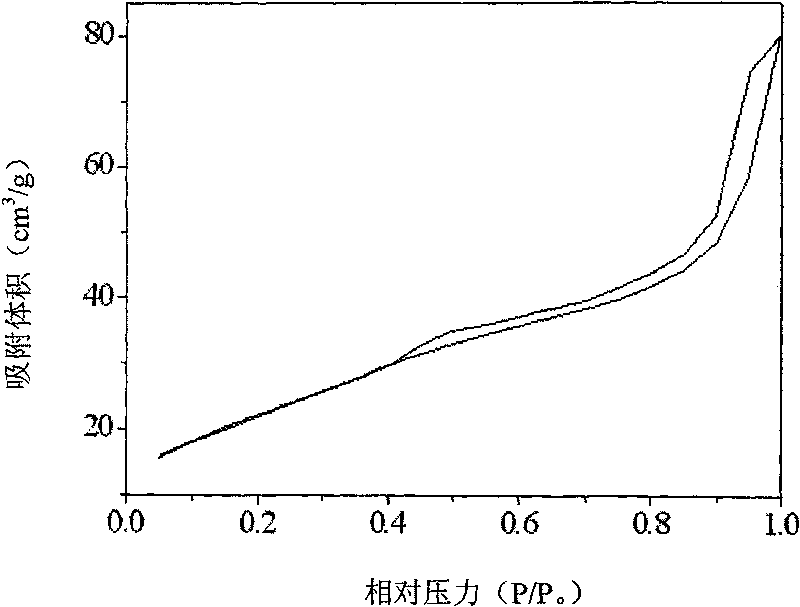

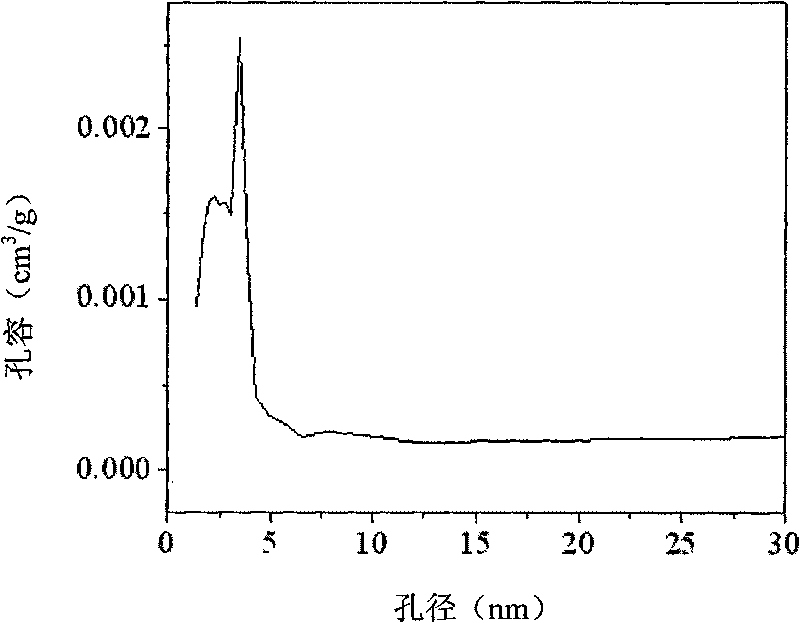

[0008] Specific embodiment one: in the present embodiment, take mesoporous silica as template and synthesize the method for high specific surface area nanometer lanthanum ferrite is to realize according to the following steps: one, La(NO 3 ) 3 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O was added in absolute ethanol at a molar ratio of 1:1 to obtain a mixed solution (red-brown homogeneous solution), wherein La in the mixed solution 3+ The concentration is 2.5mol / L, Fe 3+ The concentration is 2.5mol / L; 2. Under the condition of stirring, quickly add the pretreated mesoporous silica powder to the mixed solution obtained in step 1. Thick, then dried at 80-100°C for 20-30 hours, and ground to nanoscale; 3. Roast the ground solid at 500-900°C for 1.5-4 hours, and cool to room temperature; 4. After cooling The solid is added to the sodium hydroxide solution, stirred in a water bath at 80-100°C for 4-6 hours, then centrifuged, and washed three to five times with double distilled water; 5. T...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pretreatment method of the mesoporous silica powder in step 2 is as follows: under the condition of 80-100°C, heat the mesoporous silica powder for 4-6 Hour. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: This embodiment differs from Embodiment 1 in that the mesoporous silica powder in step 2 is mesoporous silica SBA-16 or mesoporous silica SBA-15. Others are the same as in the first embodiment.

[0012] The mesoporous silica powder in this embodiment is commercially available or synthesized according to the method in the literature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com