Paint-free self-bonding thin lumber and process for manufacturing the same

A manufacturing method and self-adhesive technology, applied in the direction of manufacturing tools, wood layered products, wood processing equipment, etc., can solve problems affecting quality, decorative nail holes, environmental pollution, etc., to reduce the impact of cross-operation and speed up construction progress and improvement of the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The gist of the present invention is to provide a series of paint-free self-adhesive veneer products, including paint-free self-adhesive veneer floor, paint-free self-adhesive veneer ceiling, paint-free self-adhesive Type) wire board, paint-free self-adhesive veneer edge banding, etc.

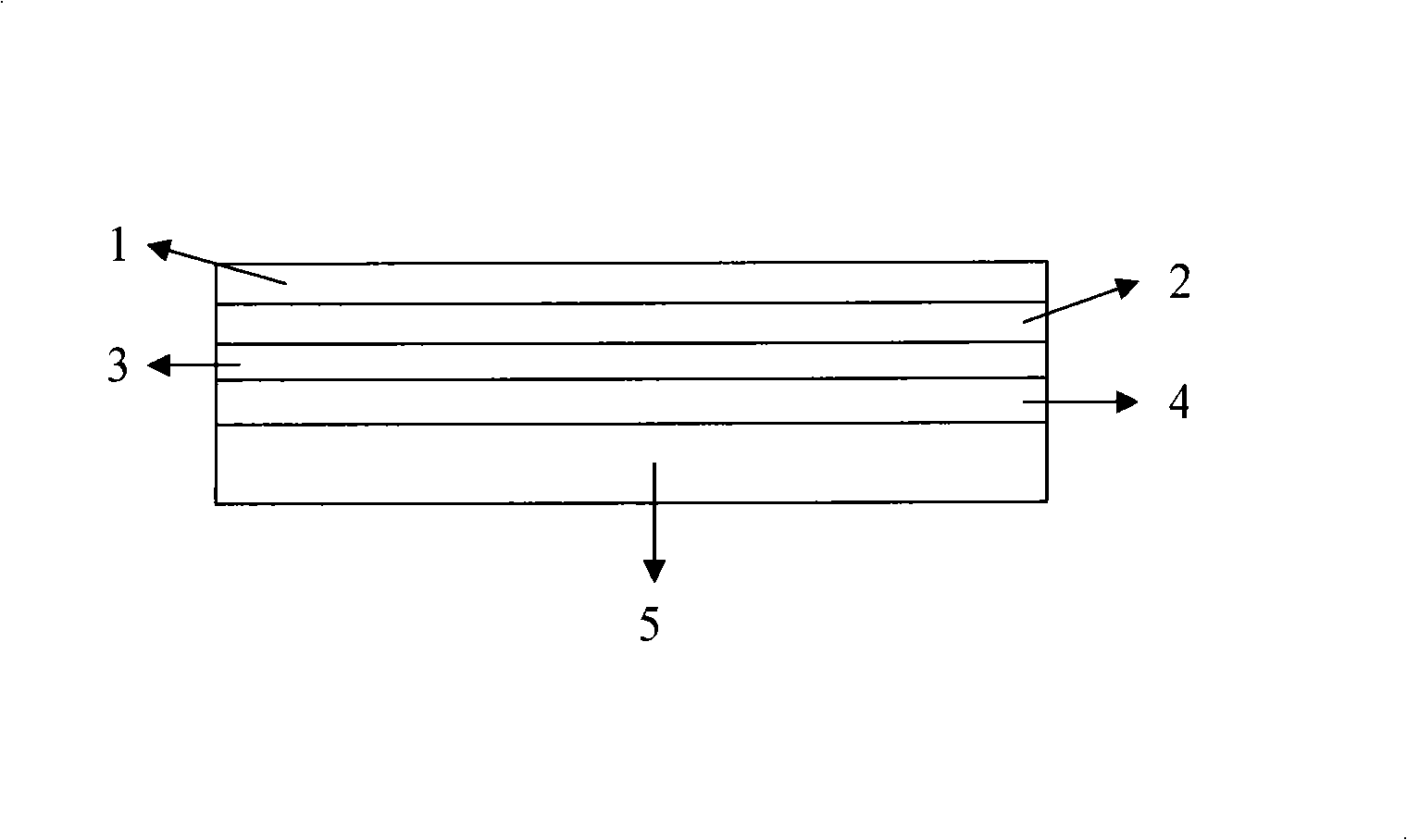

[0019] Such as figure 1 As shown, the paint-free self-adhesive veneer material of the present invention, which is pasted on the base material 5, includes a veneer material 2 that is sliced, a non-woven fabric 3 that is compositely pasted on the back side of the veneer material 2, and a non-woven fabric on the non-woven The hot-melt adhesive layer 4 rolled under the cloth is provided with a paint coating 1 on the surface of the veneer material 2 again.

[0020] Wherein, when the paint coating is a heat-resistant paint coating, the temperature-resistant performance of the heat-resistant paint coating exceeds the melting point of the hot-melt adhesive of the hot-melt adhesive layer, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com