Pipeline coupling with a sealing ring, and pipeline system for the delivery of thick matter

A pipeline joint and pipeline system technology, which is applied in the field of pipeline systems for pressurized delivery of thick substances, can solve the problems of thick substances running out, low bearing pressure of sealing lips, etc., and achieve the effect of ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

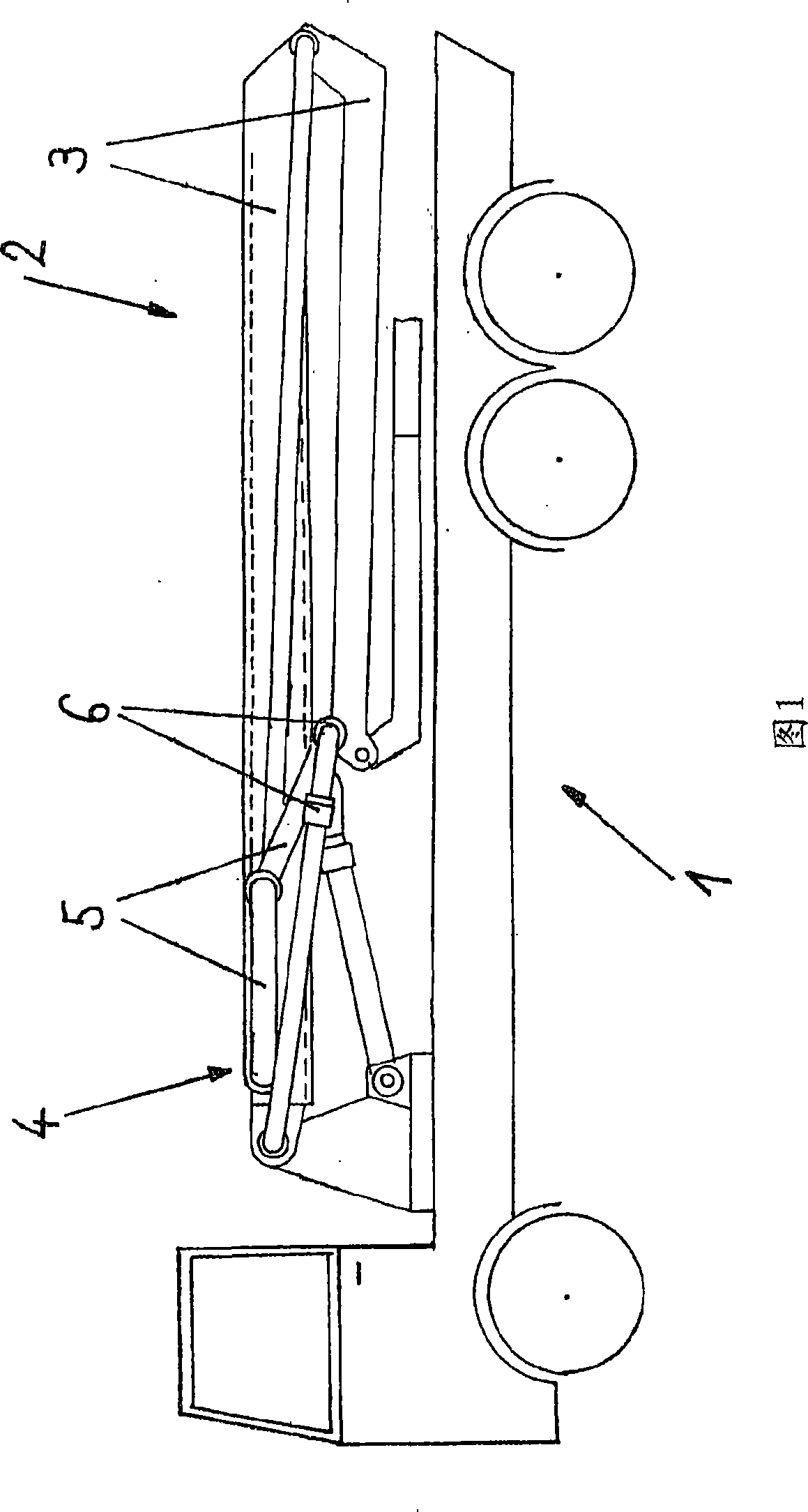

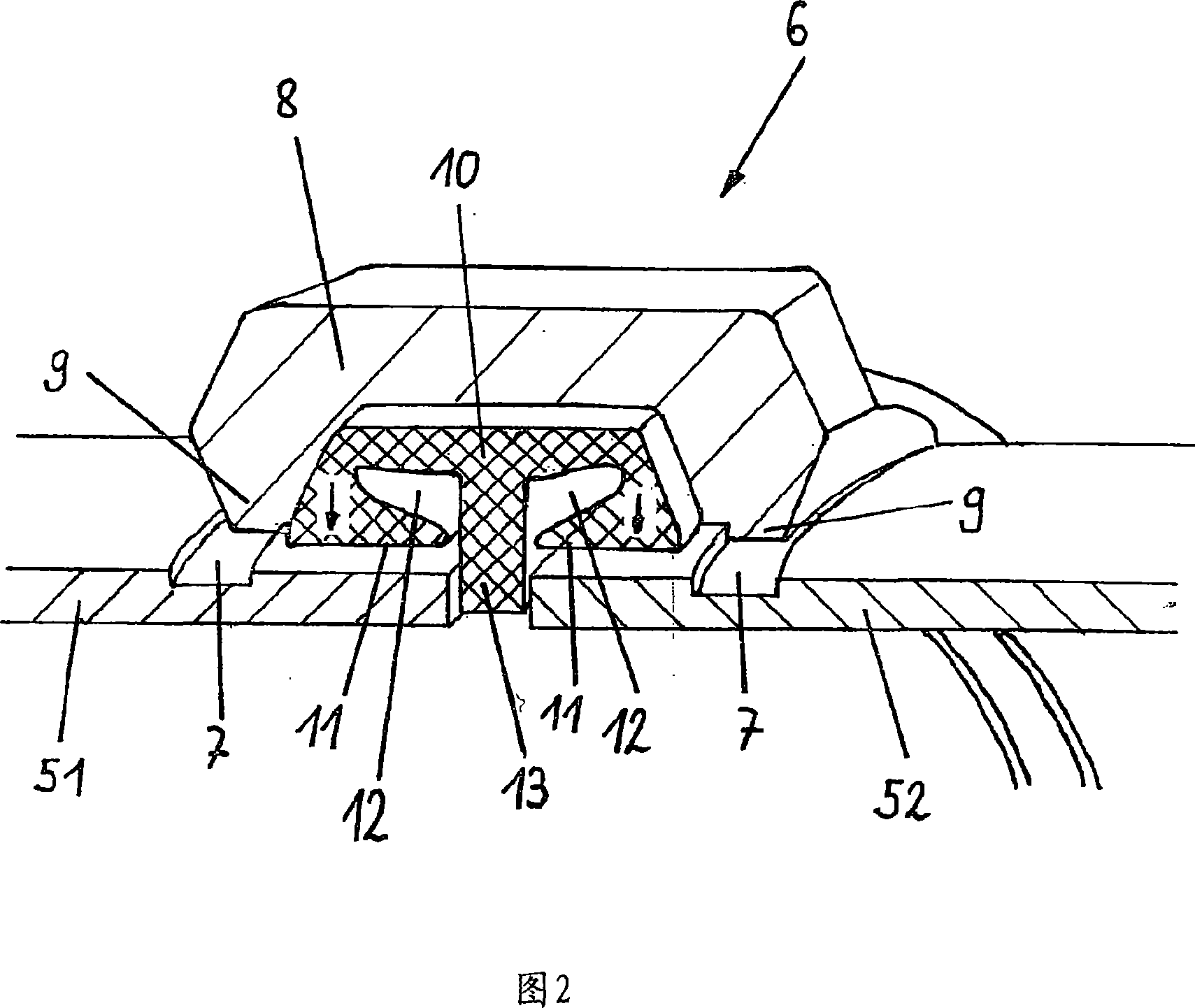

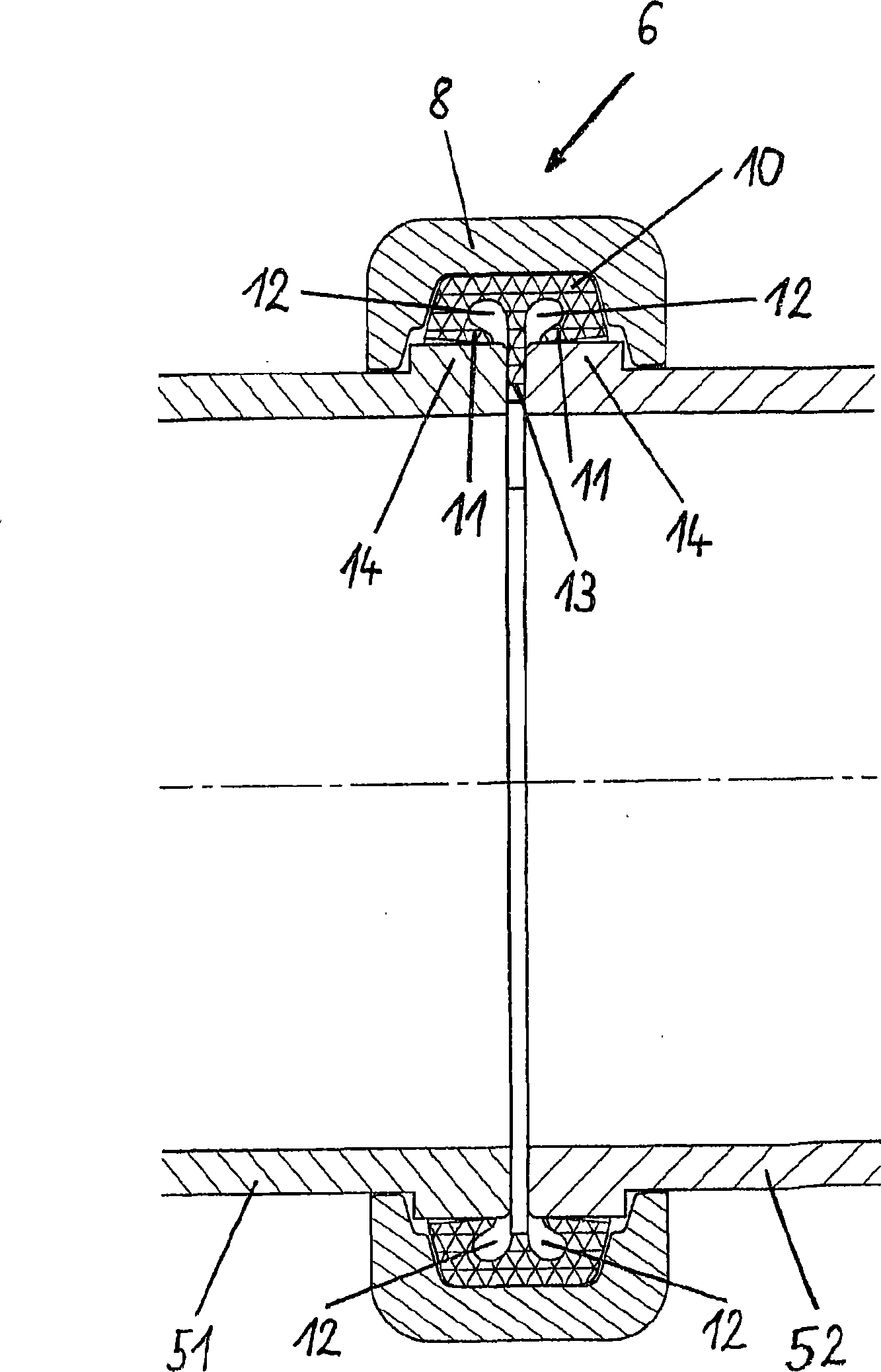

[0032] figure 1 Shown is a truck marked 1 for conveying thick substances such as concrete, mortar etc., with a swinging articulated casing 2 so that it can be conveyed, for example, over height differences. The articulated sleeve 2 is made up of individual articulated sleeve sections 3 which are telescopic and / or hinged to each other and which can be swung by hydraulic cylinders hinged at the sleeve sections. Along the hinged casing section 3 and / or also partly inside the hinged casing section is a conveying line and / or a pipeline system 4 made up of individual pipe sections 5 . A common standard diameter for such piping systems for conveying thick substances is, for example, 125 mm. Each pipe section 5 is usually connected or clamped to each other by a pipe clamp-shaped pipe joint 6, and there is a gap of a certain size inside the pipe joint 6, so that there is limited axial displacement, radial displacement, bending and / or torsion between the interconnected pipe sections. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com