Preparation for 6-chlorine-2-trichloromethyl pyridine

A technology of trichloromethylpyridine and picoline, applied in the direction of organic chemistry, can solve problems such as atmospheric environmental hazards, difficult industrialization, and impracticality, and achieve the goals of improving soil and plant nutrition, economical industrial production, and delaying nitrification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

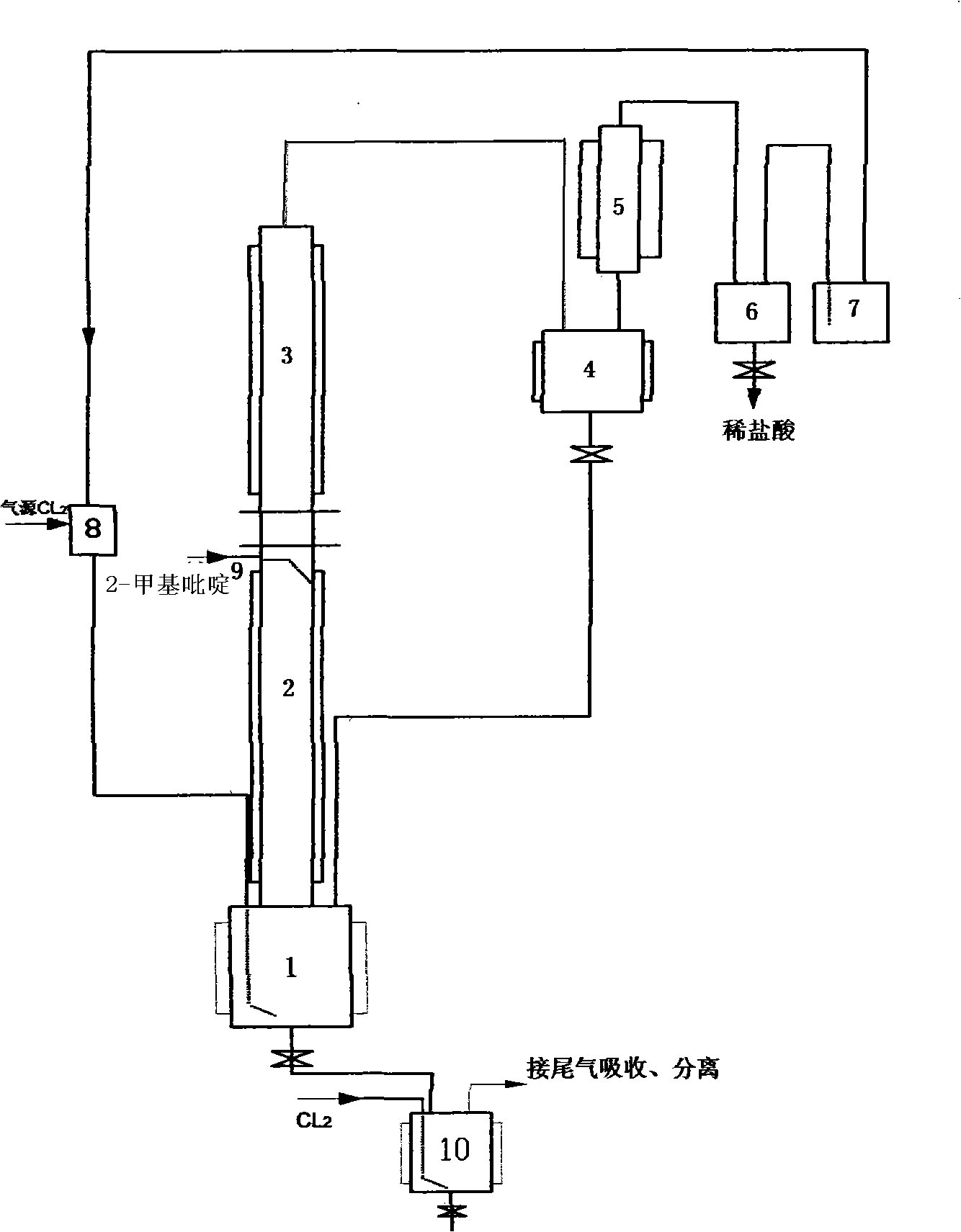

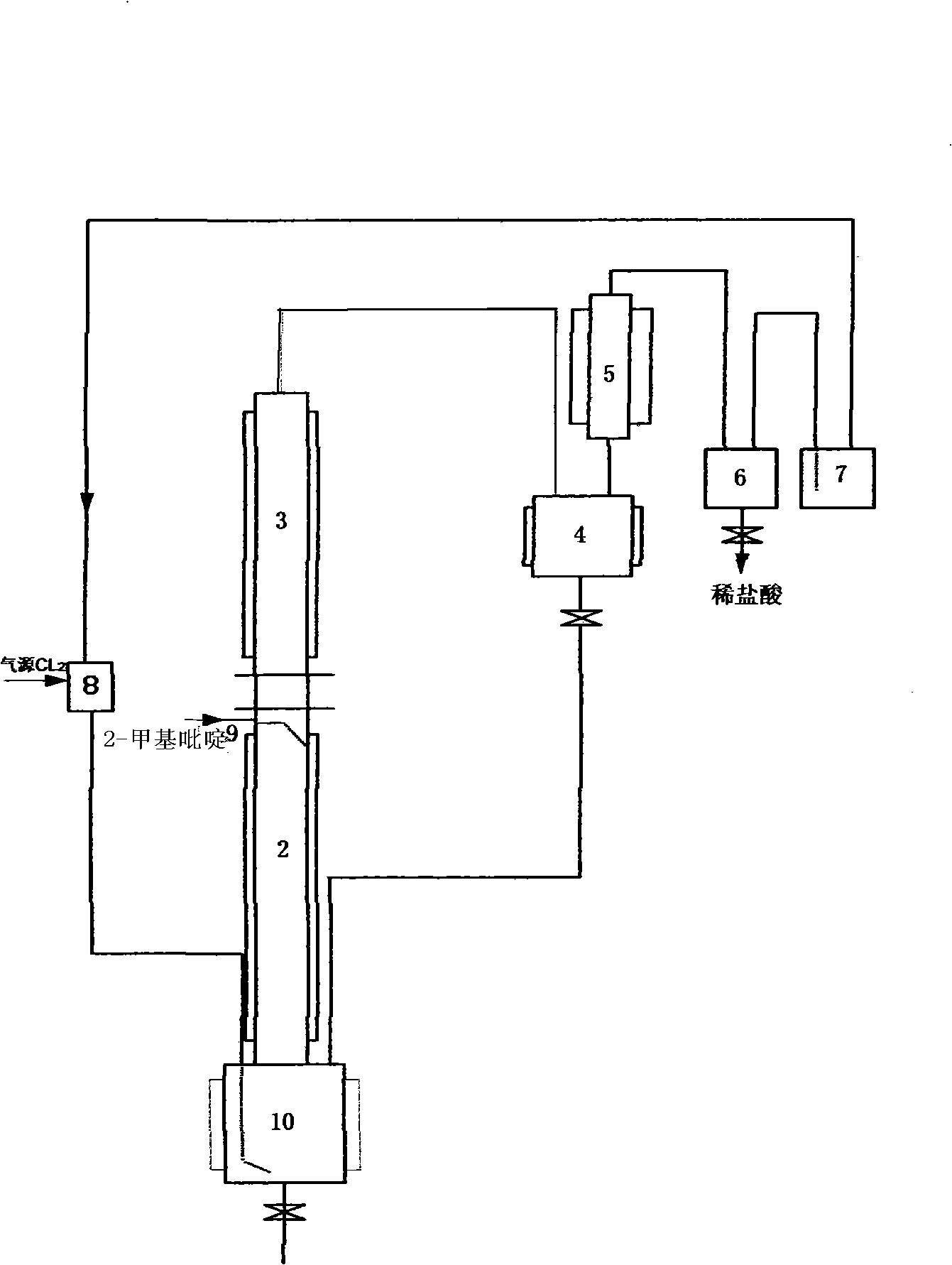

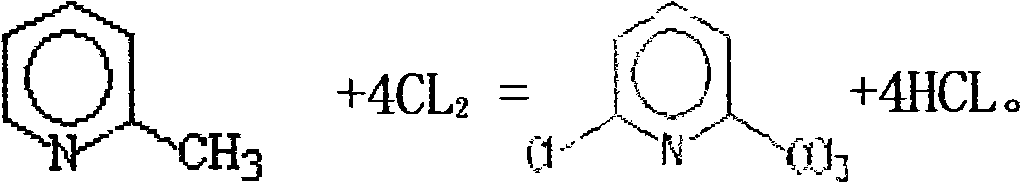

[0024] The method for preparing 6-chloro-2-trichloromethylpyridine in this embodiment mainly adopts gaseous chlorine and 2-picoline as raw materials, and adopts continuous reaction, such as figure 1 As shown, first add 200L liquid 2-picoline hydrochloride as initiator in the first reactor 1 (500L glass-lined reactor), raise the temperature to 195°C and start to feed excess chlorine gas, wherein Cl 2 Feed in at 25 kg / hour per hour, and 2-picoline is dripped on the inner wall of the second reactor 2 from the second reactor 2 along the introduction pipe 9 at 2.5 kg / hour per hour. Gaseous chlorine gas and 2-picoline hydrochloride react to generate HCL gas, HCL gas leaves the first reactor 1 and enters the second reactor 2, and reacts with 2-picoline on the inner wall of the second reactor 2 to generate 2 - picoline hydrochloride with exotherm. The second reactor 2 is temperature-controlled, using tap water as the jacket cooling water, so that the heat generated during salt format...

Embodiment 2

[0032] The method and basic steps of present embodiment and embodiment 1 are identical, adopt continuous reaction, as figure 1 shown, where changing CL 2The weight ratio to the introduced amount of 2-picoline was 4:1, chlorine gas was introduced at 10 kg / hour, and 2-picoline was introduced at a rate of 2.5 kg / hour. Reaction temperature reaches steady state in 36 hours at 195°C; the material composition when reaching steady state is 15% of 2-trichloromethylpyridine, 4.3% of 3,6-dichloro-2-trichloromethylpyridine, 6- The content of chloro-2-trichloromethylpyridine is 80%. This mixture is introduced into the chlorination reactor 10 to continue the chlorination reaction, and is irradiated with an ultraviolet lamp at a reaction temperature of 170° C. for a total of 8 hours to finally obtain A mixture of 92% chloromethylpyridine, 6.5% 3,6-dichloro-2-trichloromethylpyridine and 1.5% other impurities. Volatile matter is 85%.

Embodiment 3

[0034] The method and basic steps of present embodiment and embodiment 1 are identical, adopt continuous reaction, as figure 1 shown, where changing CL 2 The introduction weight ratio of 2-picoline was 2:1. Chlorine gas is introduced at a speed of 5 kg / hour, and 2-picoline is introduced at a speed of 2.5 kg / hour. After the reaction reaches 6 hours, it is carbonized into a black sticky tar substance. Volatile matter is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com