Six-wheel fastening mobile mechanism of two-sided window cleaner

A technology of a moving mechanism and a window cleaner, applied in the field of cleaning appliances, can solve the problems of static sliding, inability to accurately realize instant stop and go, complicated structure, etc., and achieve the effects of simple structure, high degree of automation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

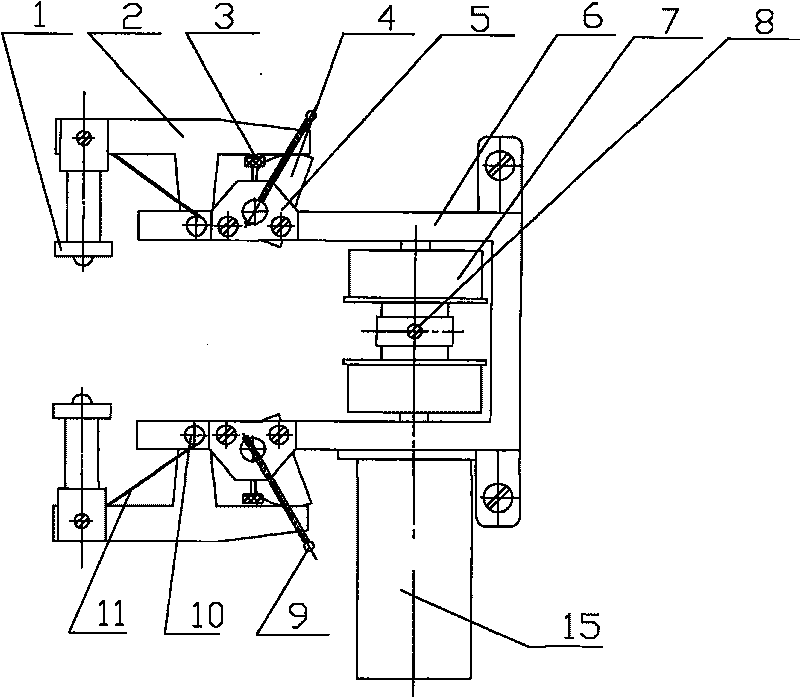

[0018] Such as Figure 1-Figure 3 As shown, the six-wheel clamping and moving mechanism of this double-sided window cleaner mainly includes a clamping body 6 of U-shaped structure, and upper shaft seats 5, cam support shafts 12, The lower shaft seat 14 and the connecting rod support shaft 10, the upper shaft seat 5 have a screw hole communicating with the cam support shaft 12, and are tightened on the cam support shaft 12 by the locking screw 3. The connecting rod supporting shaft 10 is connected with the clamping friction wheel 1 through the connecting rod body 2, and the connecting rod supporting shaft 10 is provided with a torsion spring 11 for reset; the cam supporting shaft 12 is provided with a cam 4, and the cam 4 is in the movement path It is matingly connected with the connecting rod body 2, and the connecting rod handle 9 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com