Plate type peeling machine for macadamia nut

A technology of shelling machine and nuts, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unsuitable purchasing power of domestic growers, unpublished twin-screw pod remover, nut fermentation and corruption, etc., and achieves a simple structure. , The effect of smooth entry and exit and large processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structural details of the embodiments of the present invention are described in detail below according to the drawings:

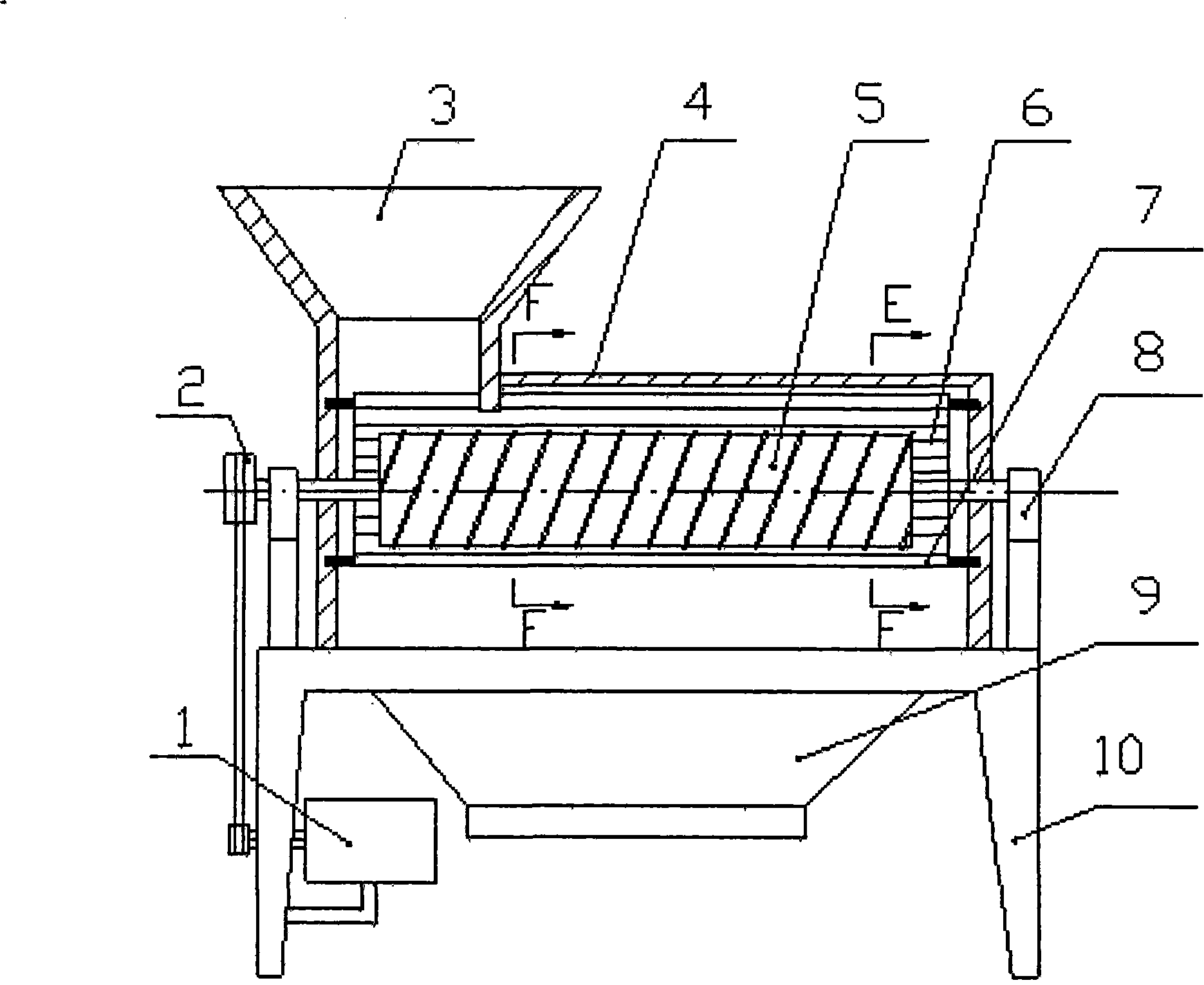

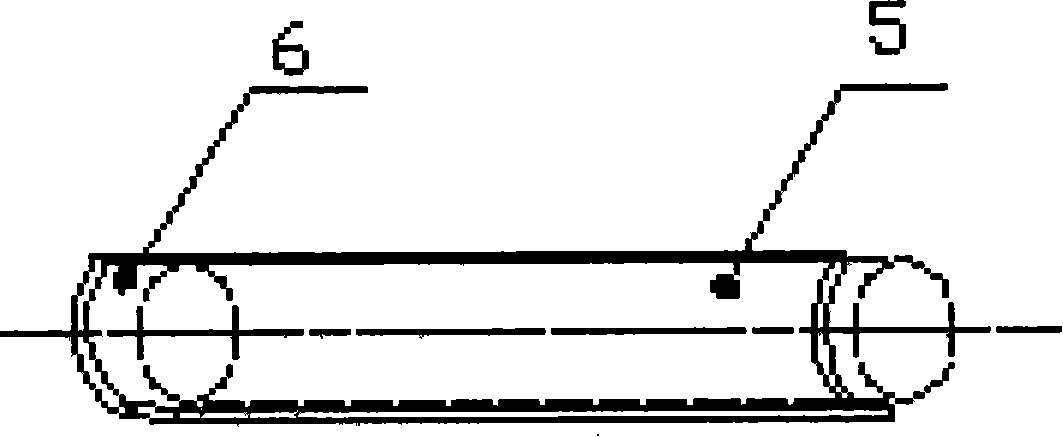

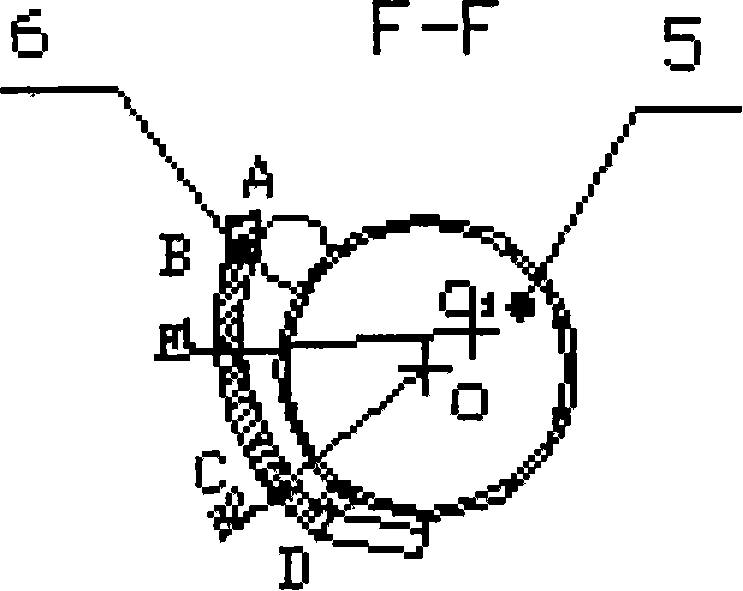

[0014] Such as figure 1 As shown, the machine is composed of a motor (or diesel engine) 1, a transmission mechanism 2, a feed hopper 3, a cover 4, a screw shaft 5, a shelling plate 6, a bearing box 7, a leather shell lead-out plate 8, a discharge hopper 9 and the machine It is composed of 10 frames. The working process of this machine is as follows: the screw shaft 5 is supported by the bearing box 7 on the frame 10, driven by the motor (or diesel engine) 1 through the transmission mechanism 2 to rotate, the shelling plate 6 is fixed on the frame, and the fruit is fed by the hopper 3 After entering, under the joint action of the screw shaft 5 and the dehulling plate 6, the fruit is squeezed during the transportation process, the peel of the fruit is cracked, and the seeds are released. The peel flows out from the gap between the hull lead-out plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com