Tyre burst sensor and tyre burst monitoring method

A tire puncture sensor and tire puncture technology, applied in the field of tire puncture monitoring and tire puncture sensor, can solve the problems of reduced battery service life, the working life cannot meet the requirements of tire puncture detection, etc., and achieves strong real-time performance and long-term low power consumption. The effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

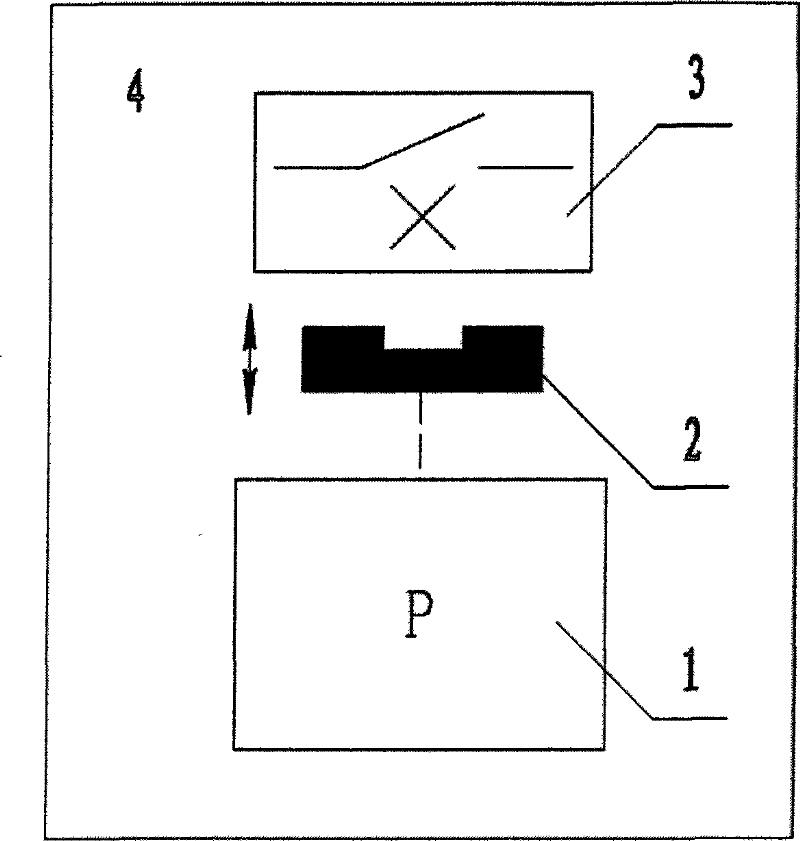

[0017] In Embodiment 2, the air pressure sensing unit adopts a sealed metal diaphragm box 1b filled with a certain pressure of nitrogen inside. The direction is the same; the magnetic sensitive switch adopts the A3212 type micro-power Hall switch 3b, which is installed in the shell 4 where the metal film box 1b can drive the permanent magnet 2 to move along the axis to change the "on" or "off" state. The PCB of the shell 4 The board 41 is used for the insulation between the Hall switch 3b and the housing 4 and the connection of the signal output circuit.

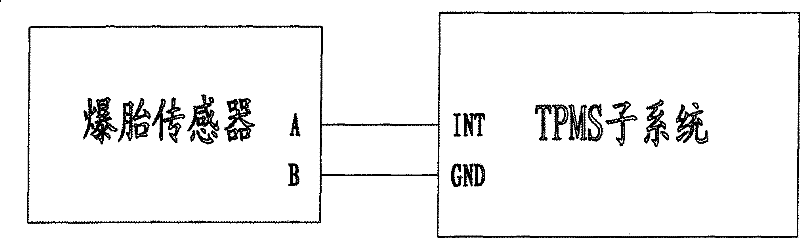

[0018] The puncture sensor is connected with the TPMS subsystem installed in the same tire (see Figure 5 ), the SUP, OUT, and GND of the Hall switch 3b are connected to the VCC, INT, and GND of the TPMS subsystem. When the tire is not inflated, the metal film box 1b is affected by its internal air pressure P, so that the permanent magnet 2 is close to the Hall switch 3b, and the Hall switch 3b is turned on under the influe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com