Tyre bursting sensor

A tire blowout sensor and tire blowout technology, applied in the field of tire blowout monitoring and tire blowout sensors, can solve tire safety hazards, unsatisfactory real-time performance and other problems, achieve strong real-time performance, and meet the effect of long-term low power consumption and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

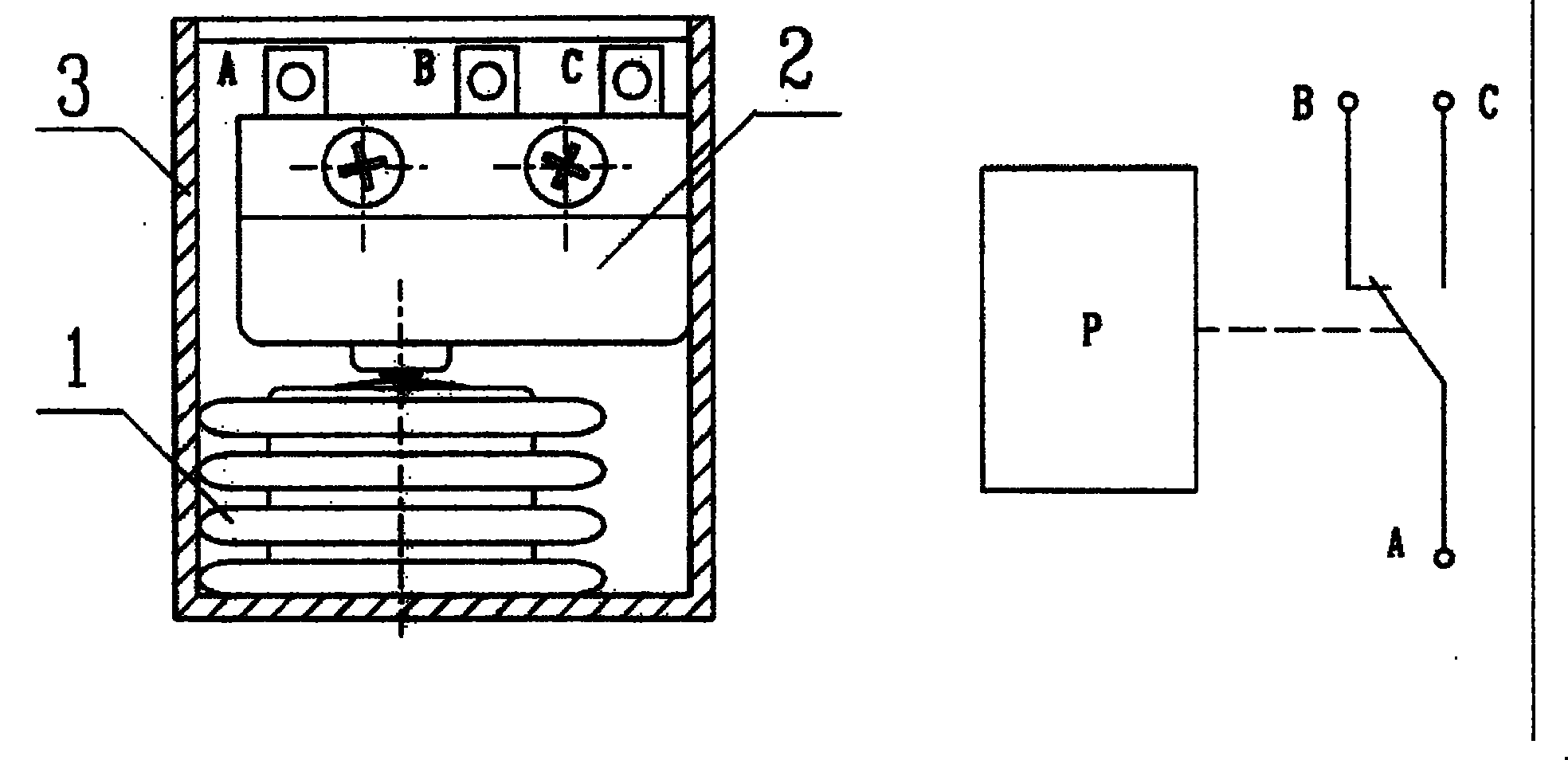

[0015] Embodiment 1 of the present invention will be described in detail below with reference to FIG. 1 , FIG. 2 , and FIG. 3 .

[0016] As shown in Figure 1, the tire burst sensor is composed of an air pressure sensing unit 1, a switch 2 and a housing 3. The air pressure sensing unit 1 adopts a sealed metal film box filled with nitrogen gas at a certain pressure inside, and the switch 2 adopts a commonly used single-pole double-throw For the micro switch, the shell 3 provides structural installation, and the switch 2 is installed at a position where the metal diaphragm box 1 can be deformed by the air pressure to cause the "open" or "close" action.

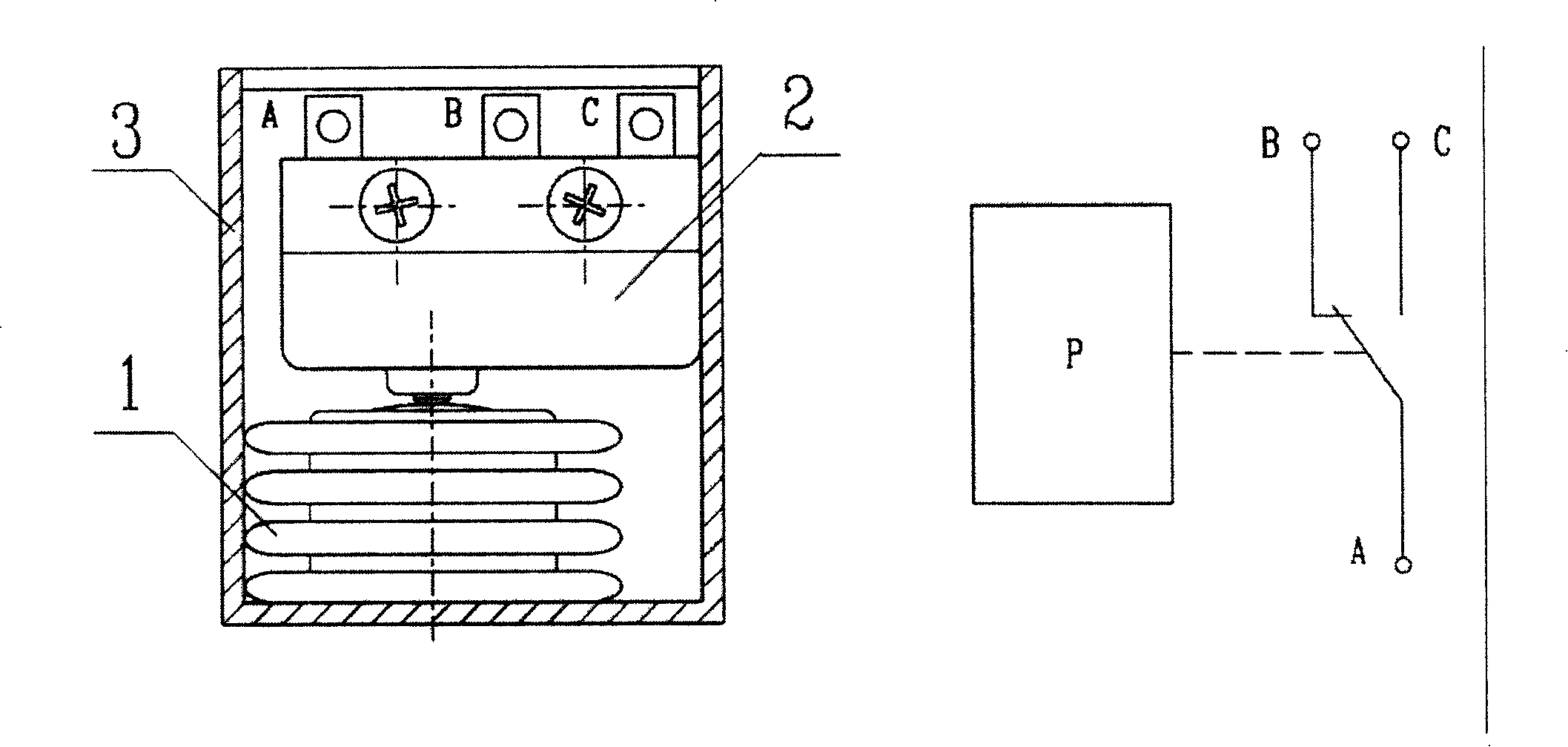

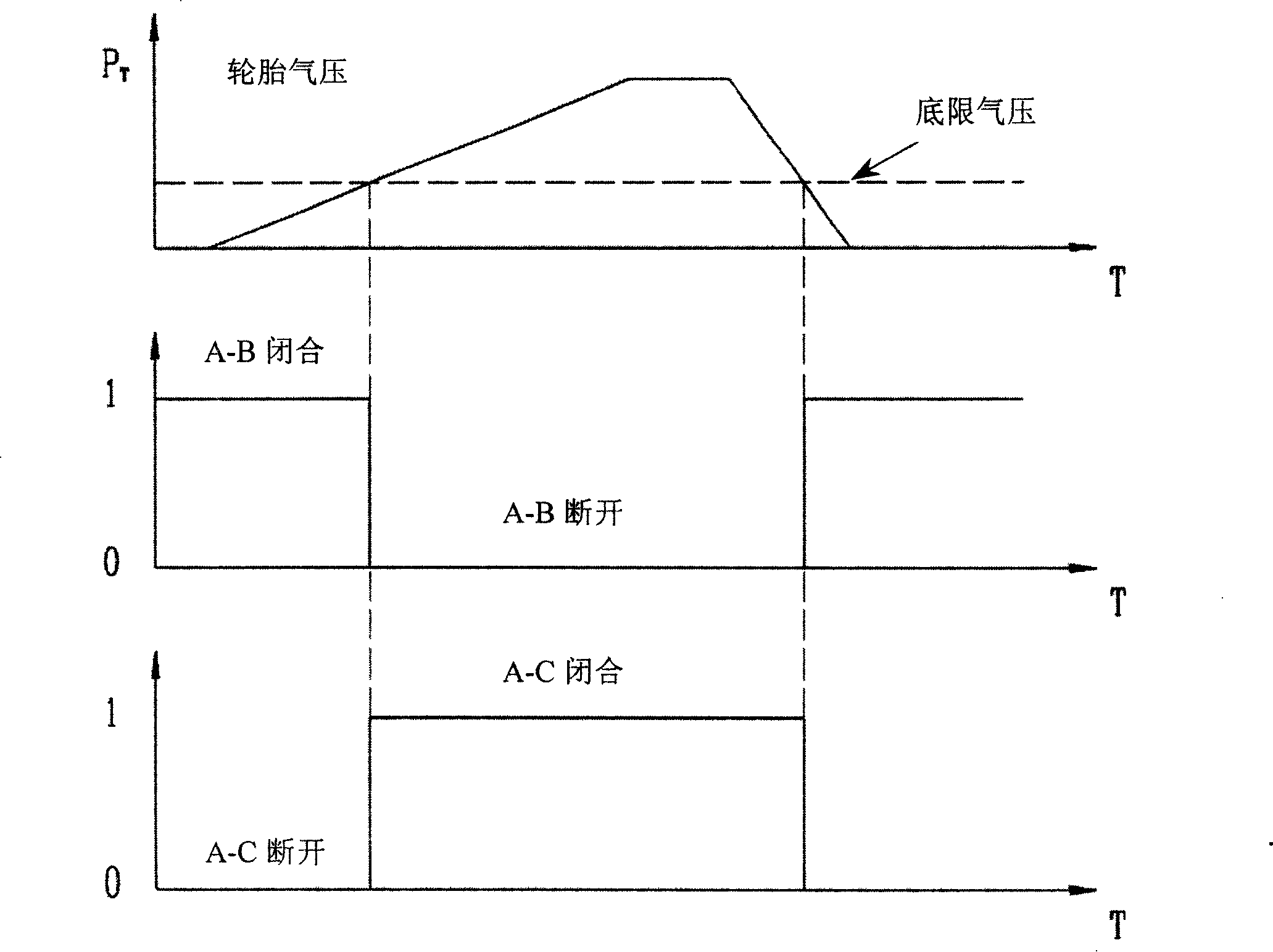

[0017] When the switch 2 of the tire burst sensor is connected to the TPMS subsystem installed in the same tire (see Figure 3), the A, B, and C terminals of the tire burst sensor are respectively connected to INT, GND, and Vcc of the TPMS subsystem, wherein, A-B is the flat tire switch, and A-C is the added start switch. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com