Chlorine liquid carburetor

A vaporizer, liquid chlorine technology, applied in pressure vessels, container discharge methods, gas/liquid distribution and storage, etc., can solve the problems of weak fixation, many thorns, unfavorable pipe penetration, and low pull-off force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

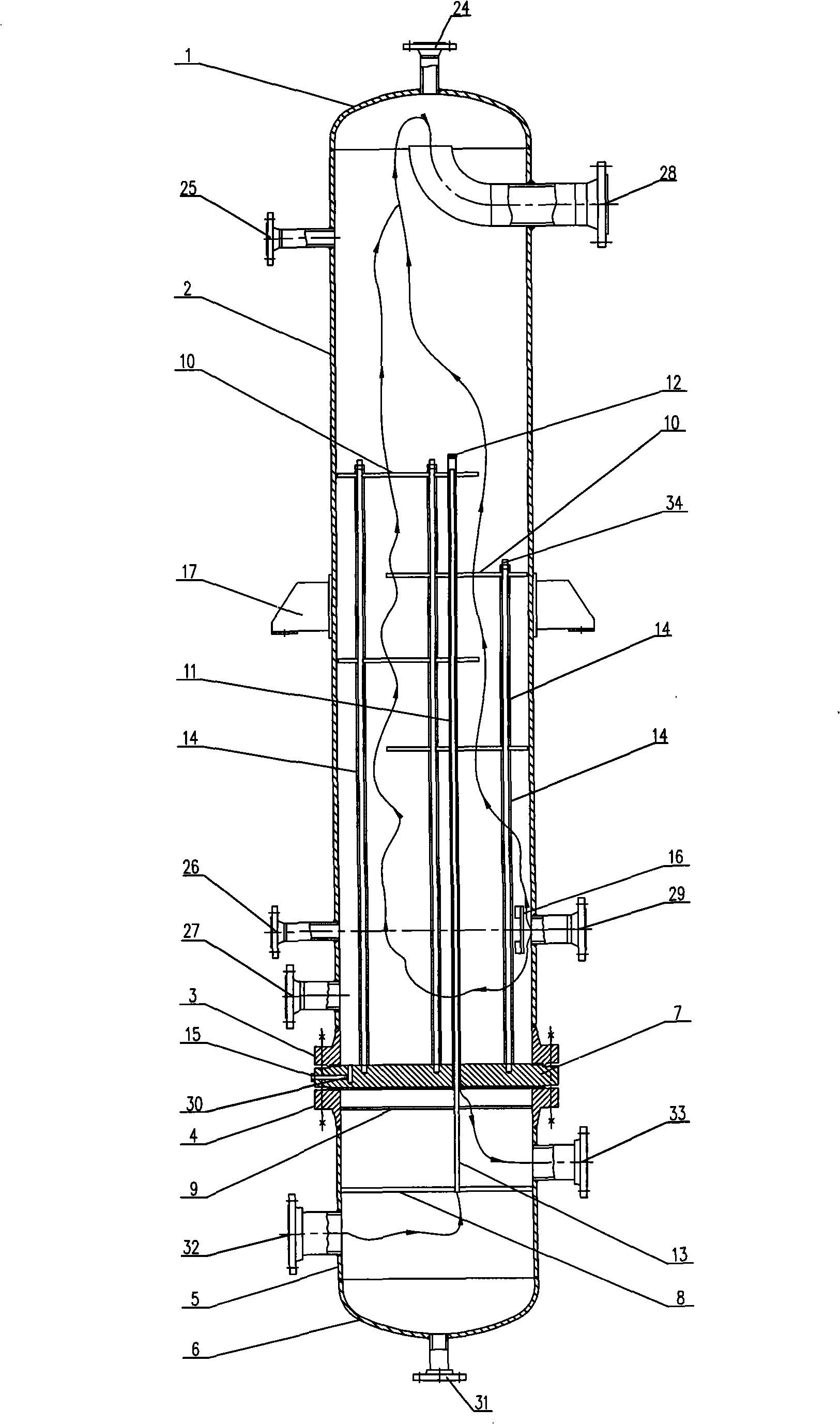

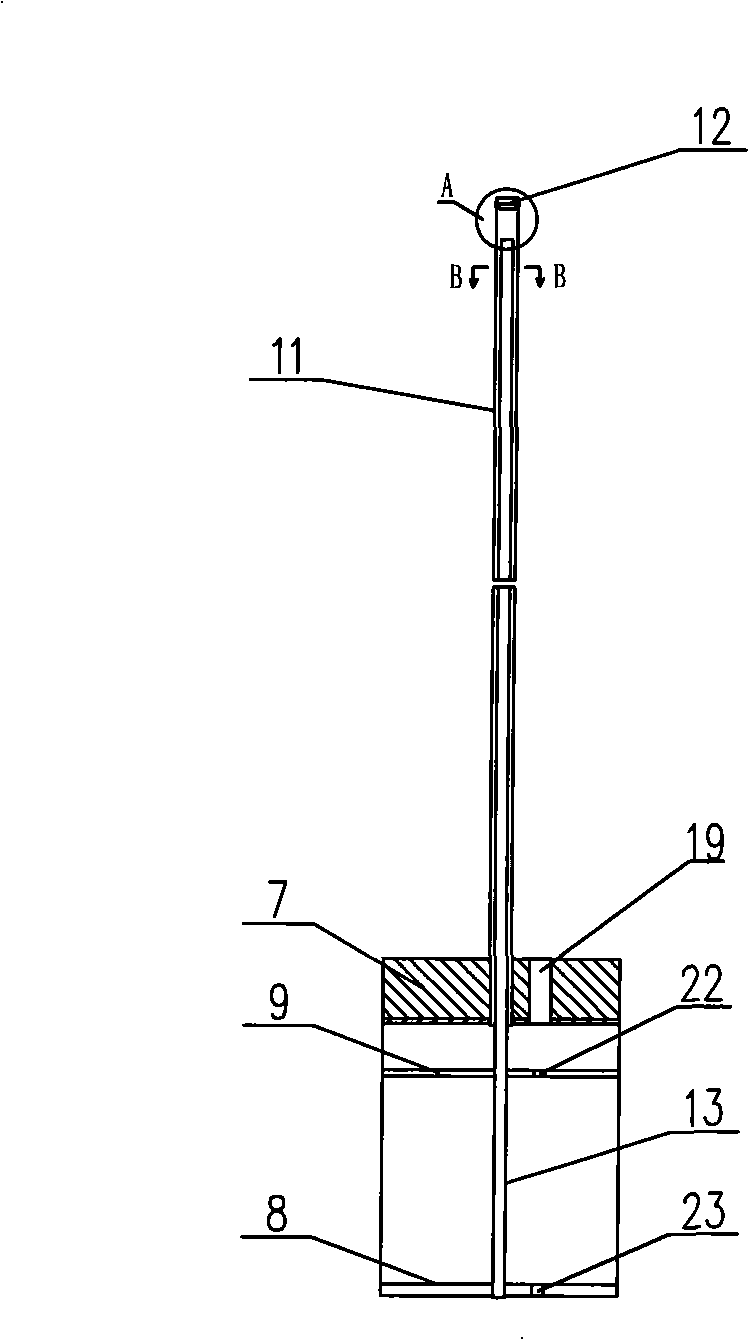

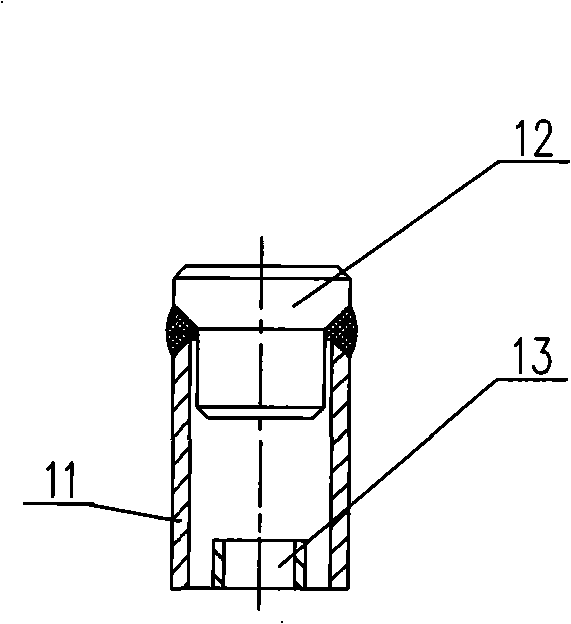

[0021] Such as Figure 1 to Figure 9 As shown, a liquid chlorine vaporizer includes a shell-side head 1, a shell-side cylinder 2, a tube-side cylinder 5, a tube-side head 6, a tube plate 7, a tube-side tube plate 8, a tube-side support plate 9, Shell side support plate 10, heat exchange outer tube 11, plug 12, heat exchange inner tube 13;

[0022] Such as figure 1 , the shell-side head 1 is connected to the shell-side cylinder 2, the tube-side cylinder 5 is connected to the tube-side head 6, and the shell-side cylinder is connected by the shell-side equipment flange 3, the tube-side equipment flange 4 and the tube sheet 7 2 and the tube-side cylinder 5 are connected together; the shell-side cylinder 2 is provided with several shell-side support plates 10, and the spacer tubes (14) are distributed between the shell-side support plates (10) and the shell-side support plates (10 ) and the tube sheet (7); one end of the tie rod (34) is connected to the tube sheet (7), and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com