Electromagentic furnace provided with magnetic induction temperature measuring equipment

A technology of temperature measuring device and induction cooker, which is applied in the field of induction cooker, can solve problems such as increased number of power outages, impact of control system, limitation of temperature detection, etc., and achieves the effects of improving automation, easy implementation, and widening applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

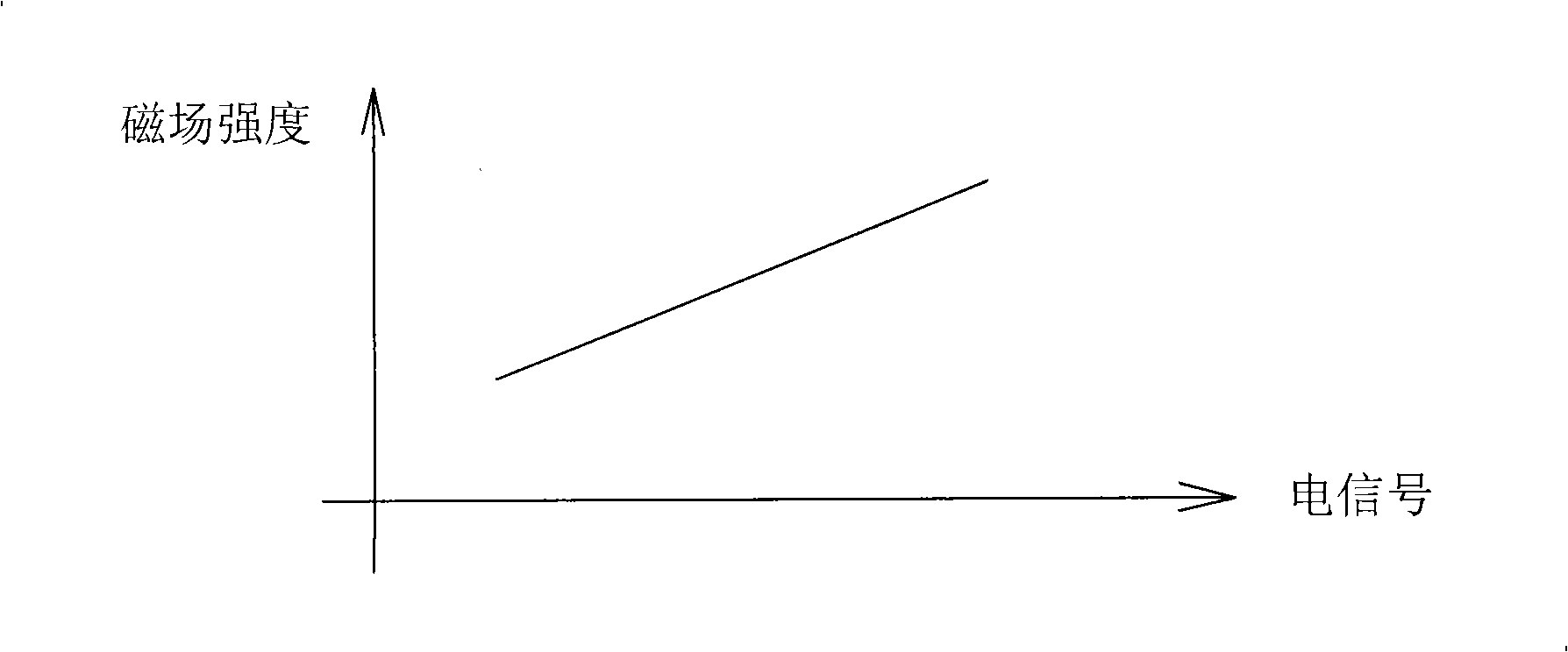

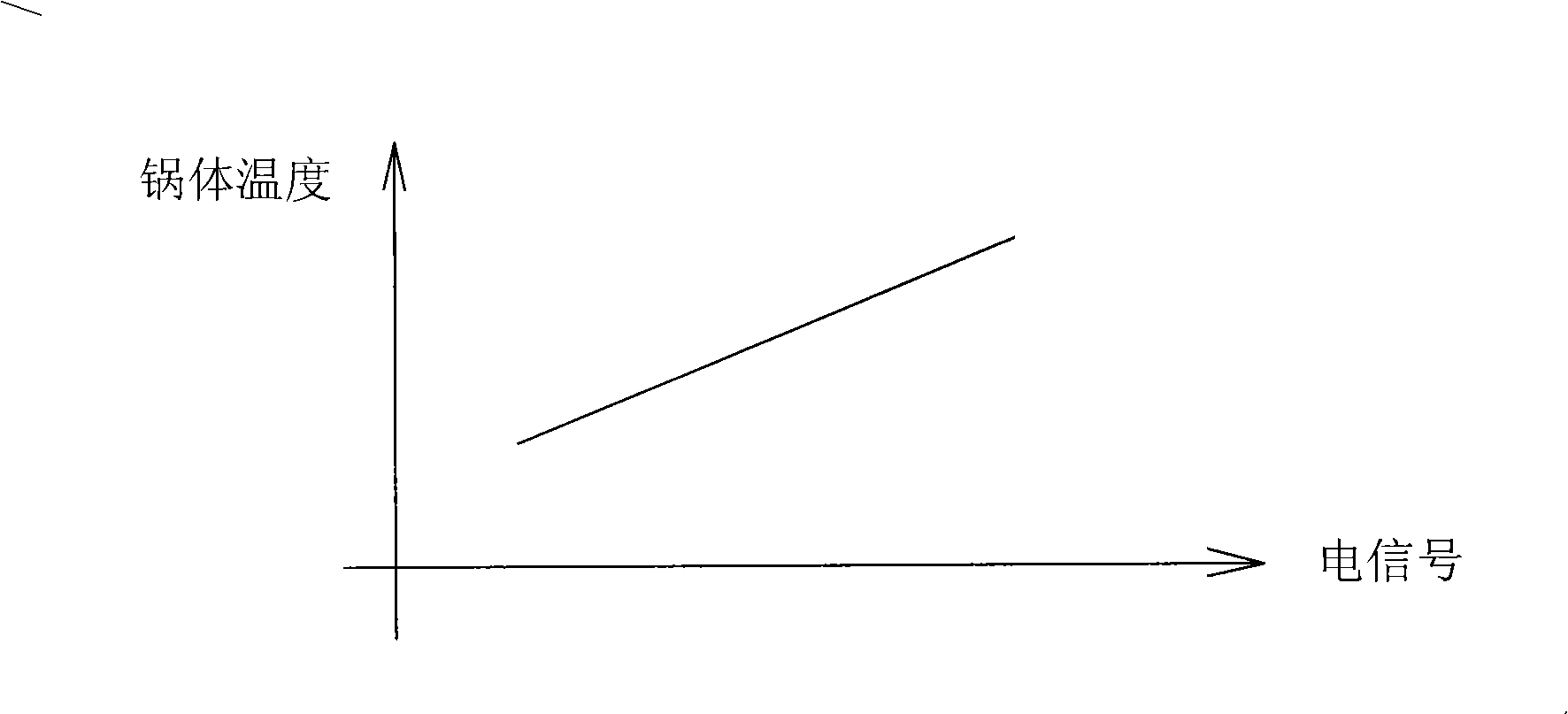

[0036] Such as Figure 4 , Figure 5 , Figure 6 The shown induction cooker provided with a magnetic induction temperature measuring device is one of embodiments of the present invention, comprising an induction cooker shell 2, an induction cooker platen 3, a heating coil 4 and a control circuit, the control circuit comprising a control board 1 and a drive board 8, heating The center of the coil 4 is provided with a bracket 5 on which a thermistor 7 is mounted. There is also a temperature-measuring induction coil 6 below the induction cooker table 3, which is used to convert the magnetic signal generated by the magnetic temperature sensing element 10 above the induction cooker table 3 at a set temperature point into an electrical signal and output it. The coil 6 is matched with the heating coil 4 and can generate an induction electric signal. The temperature-measuring induction coil 6 is located near the heating coil 4 and the magnetic temperature-sensing element 10, in an ...

Embodiment 2

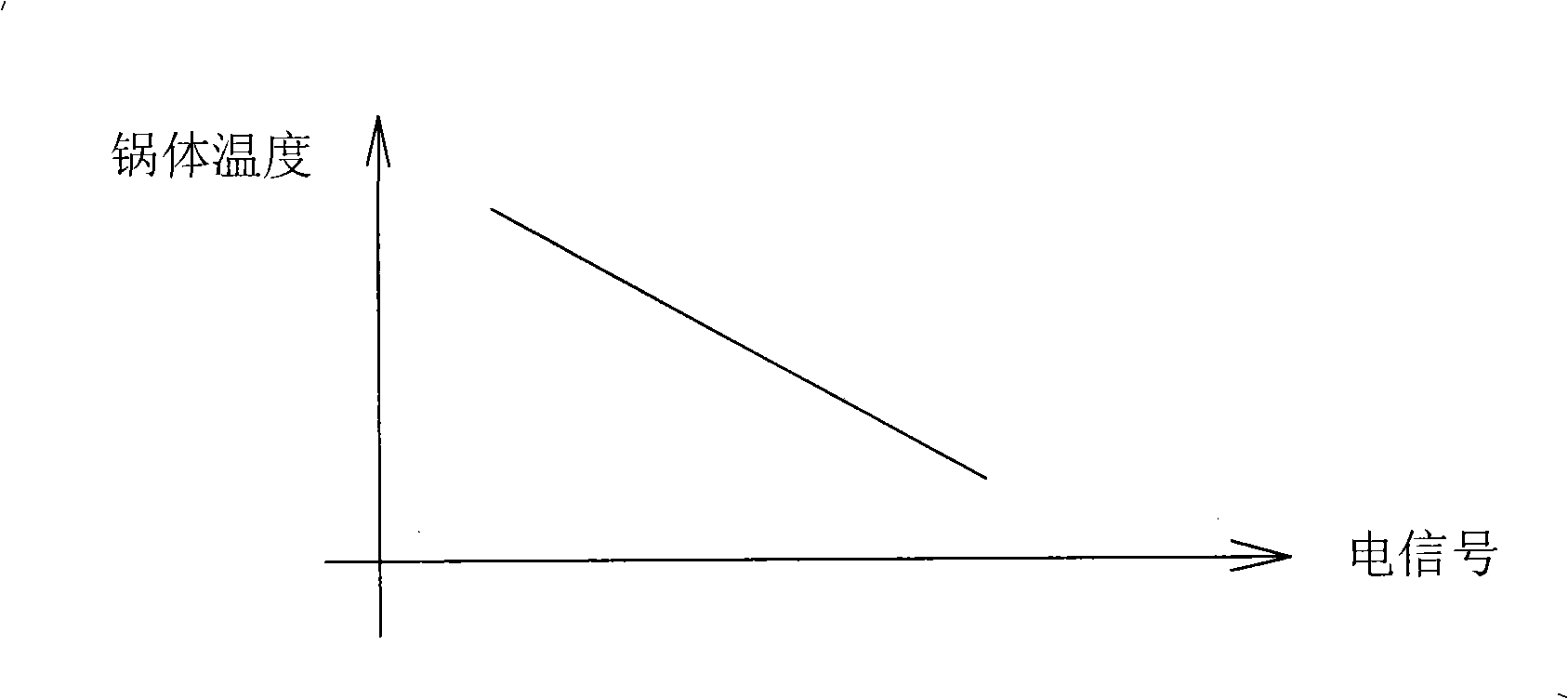

[0041] Such as Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 The electromagnetic oven shown with a magnetic induction temperature measuring device is the second embodiment of the present invention. The difference from Embodiment 1 is that the temperature measuring induction coil 6 is located in the center of the heating coil 4, and the magnetic temperature sensing element 10 adopts thermosensitive ferrite Material, when the induction cooker is working, under the same magnetic field strength, the magnetic flux passing through the temperature measuring induction coil 6 is the largest. The temperature measuring induction coil 6 and the thermistor 7 are fixed below the induction cooker platen 3 by the bracket 5 . The bracket 5 is a ladder-shaped frame with a longitudinal section, the thermistor 7 is fixed on the higher frame, and the temperature-measuring induction coil 6 is fixed on the lower frame. The magnetic temperature-sensing element 10 is centrally fixed...

Embodiment 3

[0047] Such as Figure 12 , Figure 13 , Figure 14 The shown electromagnetic cooker provided with a temperature measuring device is the third embodiment of the present invention. The difference from Embodiment 2 is that the magnetic temperature sensing element 10 is a temperature-sensitive magnetic steel made of nanocrystalline material, and the electromagnetic cooker is equipped with a specific electromagnetic cooker 9 In use, the magnetic temperature sensing element 10 is directly located at the bottom of the electromagnetic cooker 9 with a double-layer structure for supporting use. The electromagnetic cooker 9 has an outer shell 91 and an inner shell 92. The heat of the electromagnetic cooker with this structure is not easy to lose, and the heat preservation Better results. The magnetic temperature sensing element 10 is located between the two layers of shells, that is, the outer shell 91 at the bottom of the electromagnetic cooker 9 is directly in contact with the induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com