Prefabricated hollow pile sinking method

A technology of hollow piles and pile sinking, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., and can solve problems such as broken piles or large pile settlements, large discrete pile side resistance, and reduced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

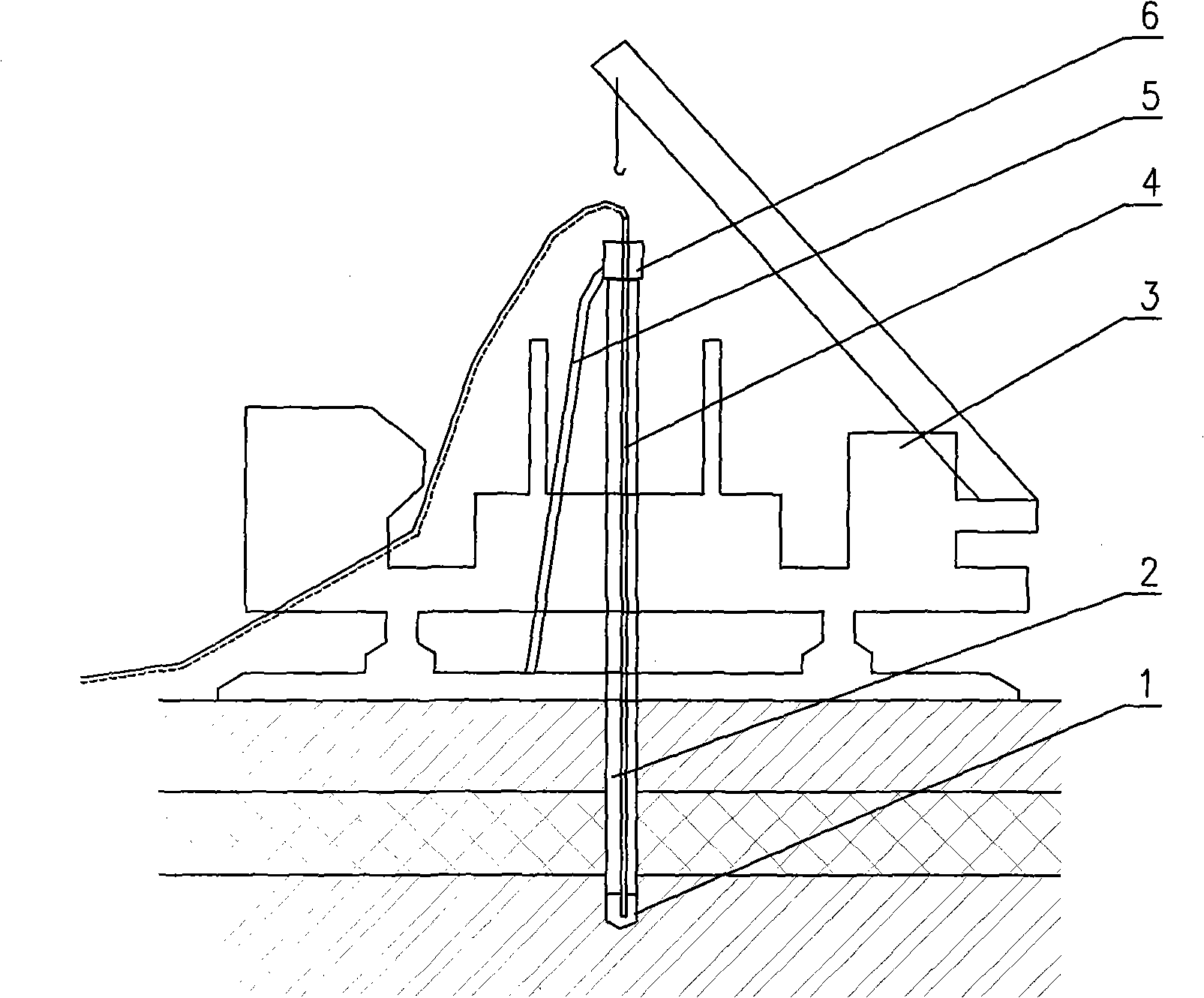

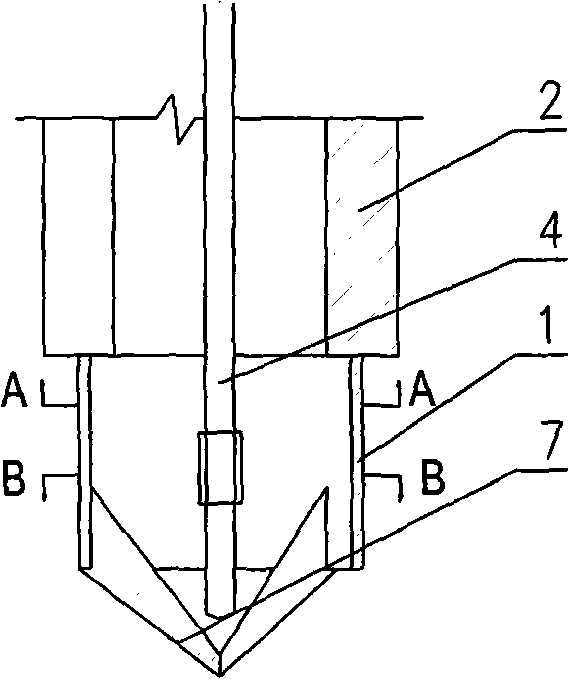

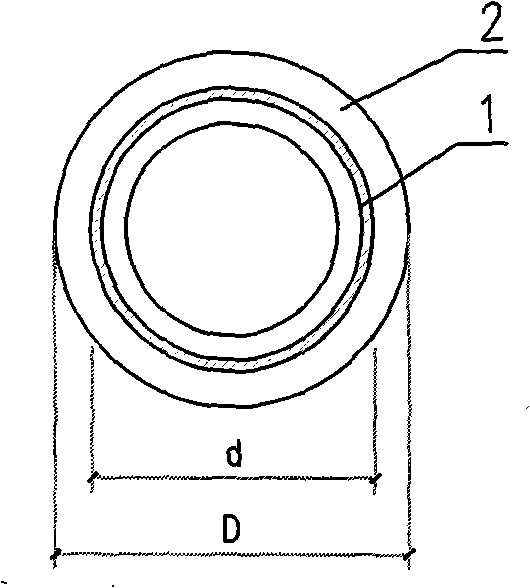

[0014] Make the pile point first, such as figure 2 , image 3 , Figure 4 Shown, the end of pile tip 1 is equipped with cutting knife 7, closes pile tip with higher intensity, the soil that meets water and disperses easily, such as: loess is mixed into mud, mud is filled in the cavity of pile tip, aired Dry. The pile tip 1 is welded to the end of the prefabricated hollow pile 2, and the pile top drainage bucket 5 and the drainage pipe 4 are fixed with screws. The outer diameter d of the pile tip is not greater than the outer diameter D of the prefabricated hollow pile and not smaller than the inner diameter of the prefabricated hollow pile. The prefabricated hollow pile 2 is placed on the pile driver 3. After the pile driver 3 is in place, the pile is quickly pressed through the miscellaneous filling soil layer. Because there is dry mud in the pile tip, the soil outside the pile tip cannot enter the pile tip. Then the pile is pressed at a slow speed, and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com