Process for removing nonmetal inclusion in molten steel

A non-metallic inclusion and molten steel technology, applied in the field of pure steel smelting, can solve the problems of only 1 to 3 minutes, no more than 5 minutes, fast consumption of the horn, small action area, etc., to reduce the number of inclusions, Wide range of action, the effect of increasing the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

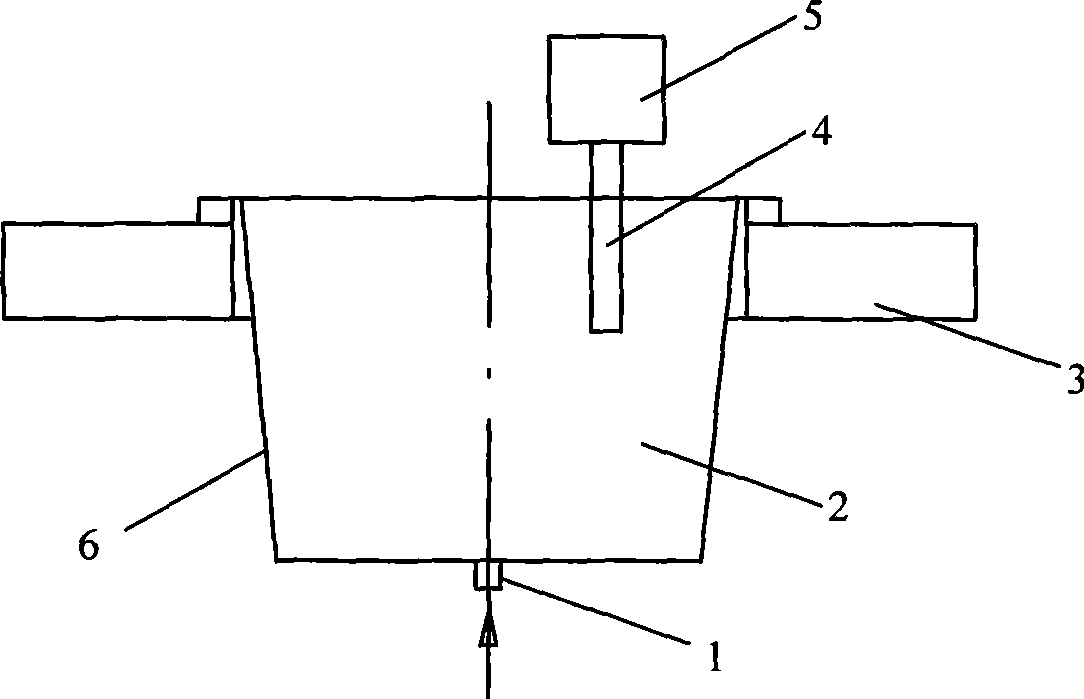

[0015] The method of the present invention is different from the application of ultrasonic waves in the crystallizer or RH degassing ladle or tundish introduced in the JP06220551A patent. Pneumatic stirring, one or several horns are extended to the middle and lower part of the molten steel 2, and the ultrasonic wave is introduced into the molten steel 2 through the horn 4, and a large number of fine air bubbles are generated by using its strong impact and cavitation effect, increasing Adsorb and capture the area of inclusions, improve the collision chance of bubbles and inclusions and the coagulation effect of inclusions, and achieve the purpose of rapid growth, floating, separation and removal.

[0016] The operation steps are as follows: first, hoist the ladle 6 containing the molten steel 2 on the turntable 3; start blowing Ar gas through the Ar blowing port 1 and stir for a maximum of 2 minutes, then stop blowing Ar gas to generate a certain number of bubbles in the molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com