Process method of tripod ball inner sliding sleeve capable of axially moving and back extrusion concave die

A technology of axial movement and three-ball pins, which is applied in the direction of metal extrusion dies, etc., can solve the problems of insufficient metal of the inner sliding sleeve of three-ball pins, affecting product quality, metal flow, and unreasonable volume distribution, etc., to improve product quality. Quality, increase the effect of metal fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

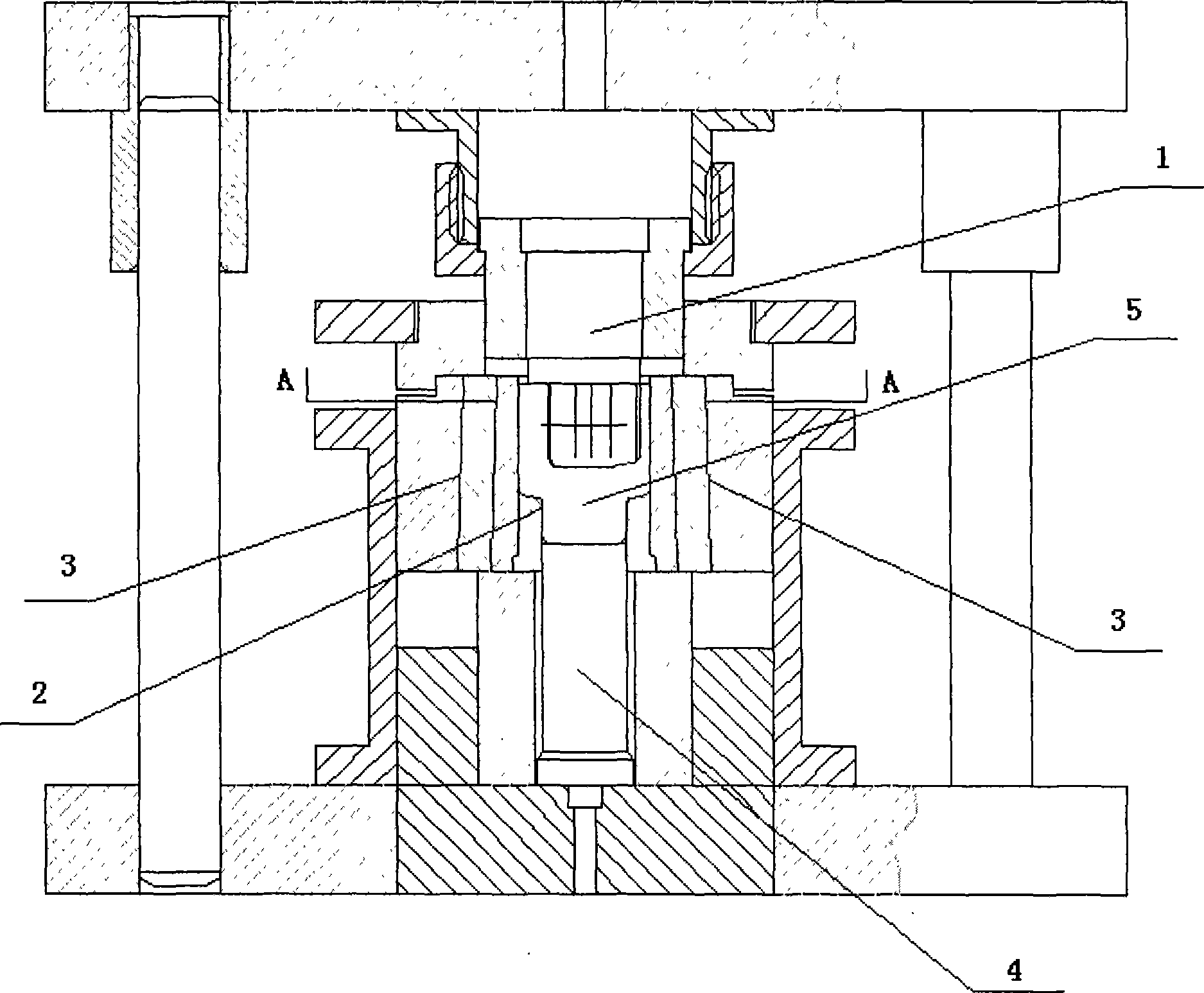

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0019] The processing method of the inner sliding sleeve of the three-ball pin that can move axially:

[0020] ①Blanking, intercepting bar;

[0021] ② Upsetting, heating the bar to a temperature of 900°, upsetting in the upsetting die to form two cylinders of different sizes and diameters and the transition section between them;

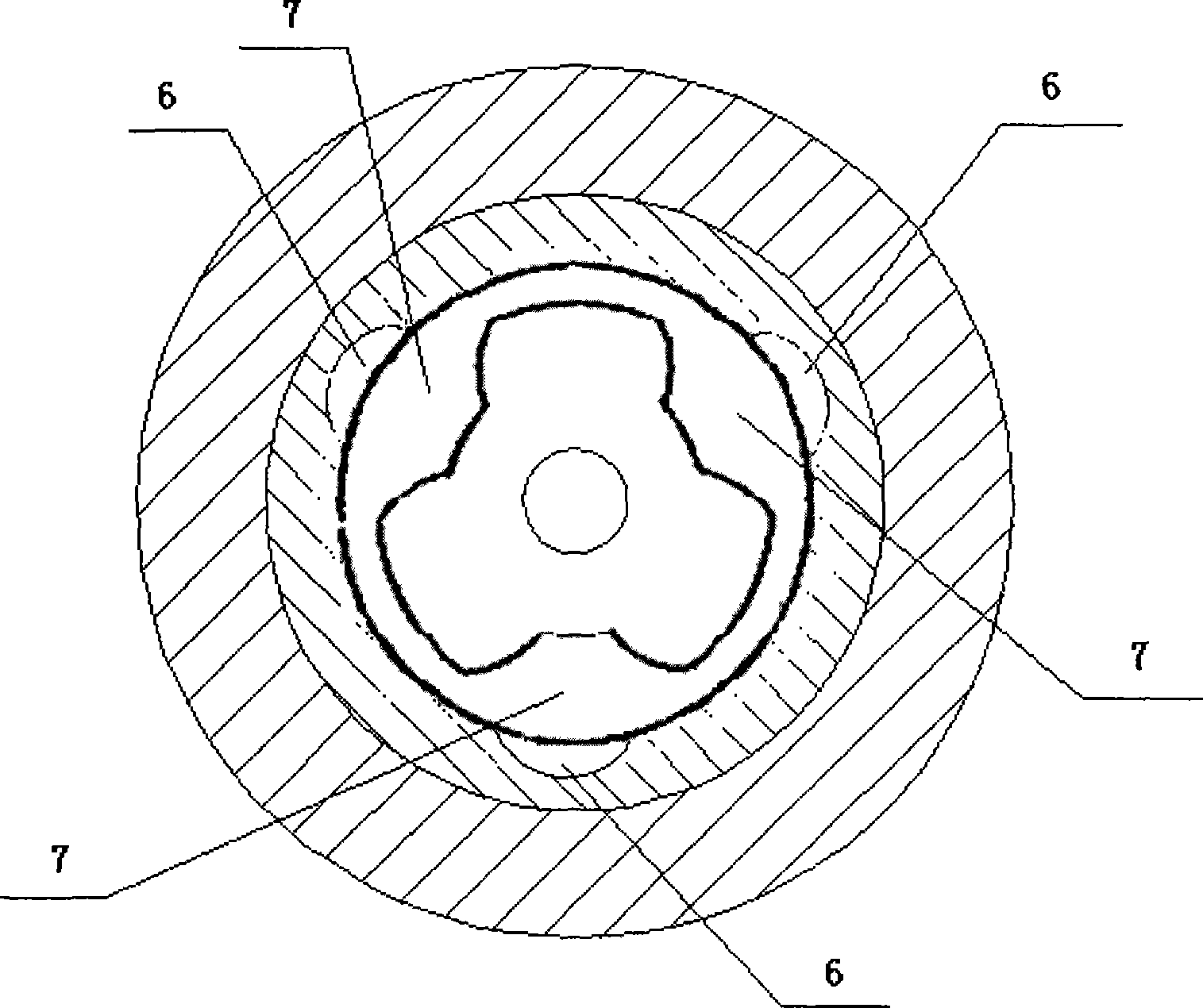

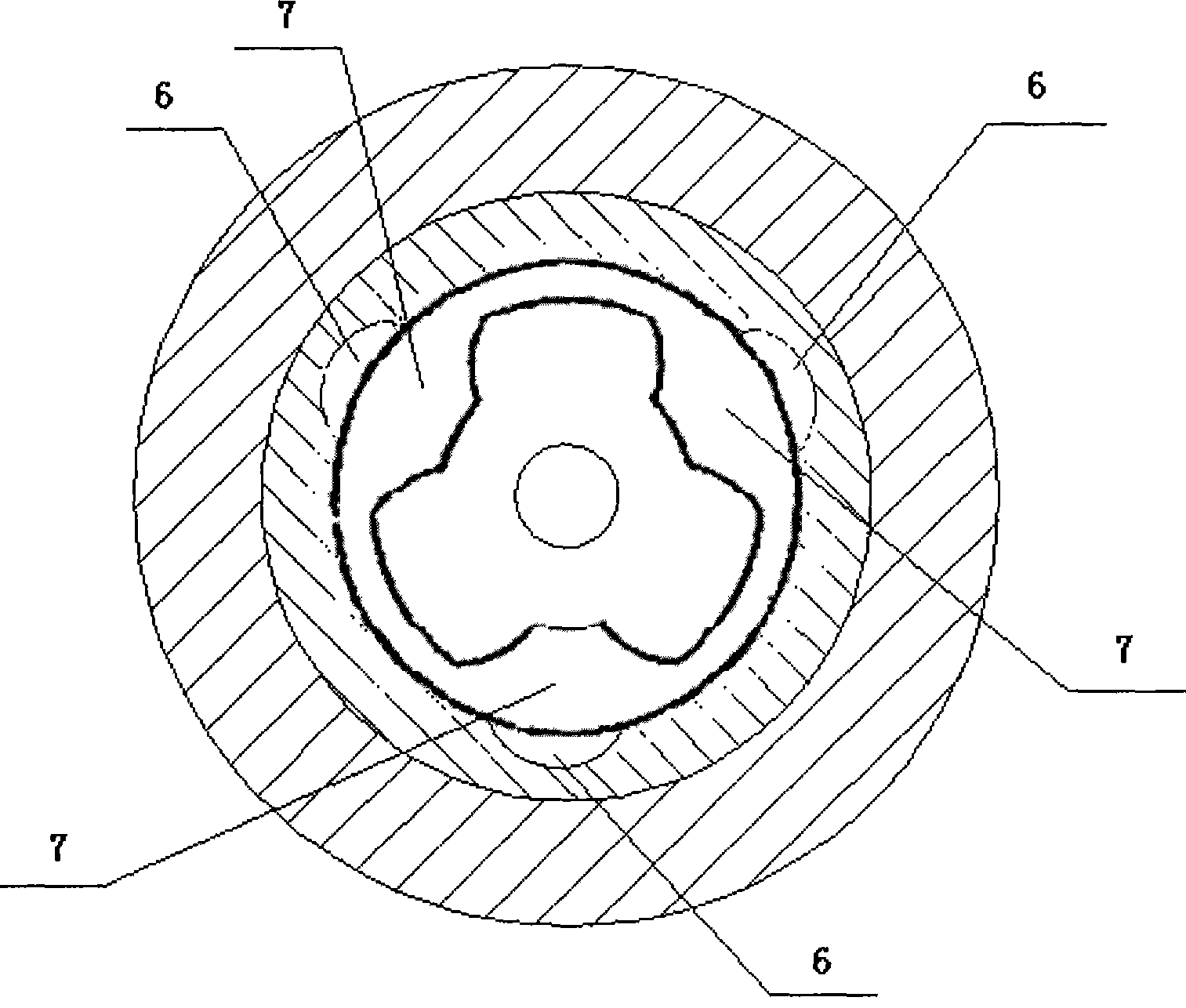

[0022] ③Reverse extrusion in a hot state. In the reverse extrusion die, the punch is used to back-extrude the large cylinder so that the inner hole of the large cylinder forms a three-ball pin lane;

[0023] ④ After annealing, cool to normal temperature, perform shot blasting, phosphating, and saponification treatment, and obtain the semi-finished product of the three-ball pin inner sliding sleeve;

[0024] ⑤Using the finishing mold to finish and extrude the inner hole fair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com