A construction waste metal separation device

A technology for metal separation and construction waste, which is applied in solid separation, magnetic separation, cleaning methods and utensils, etc., can solve the problems of reduced adsorption capacity and reduced work efficiency, and achieves the improvement of service life, work efficiency, and separation quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

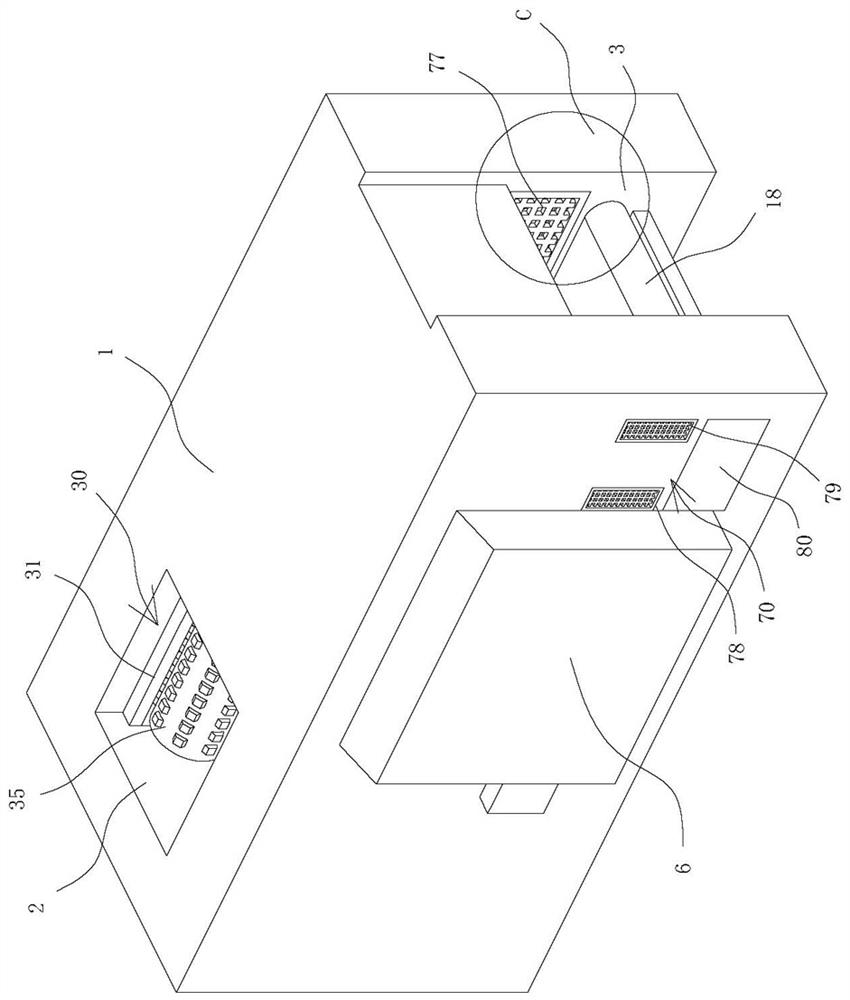

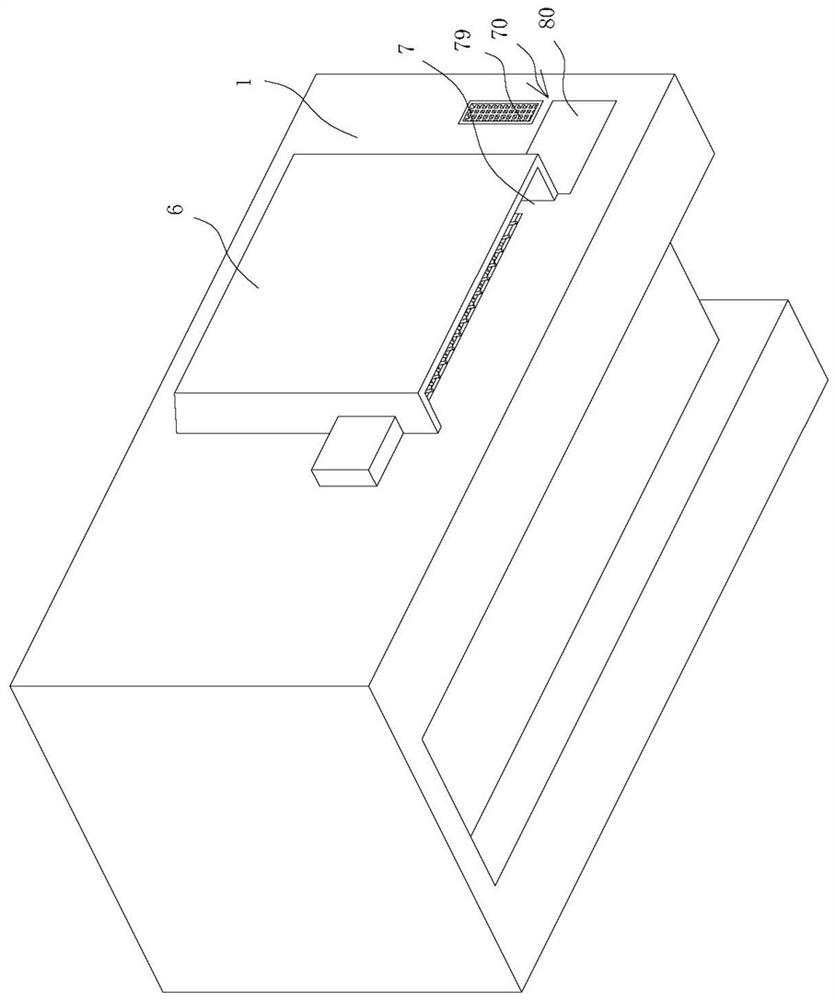

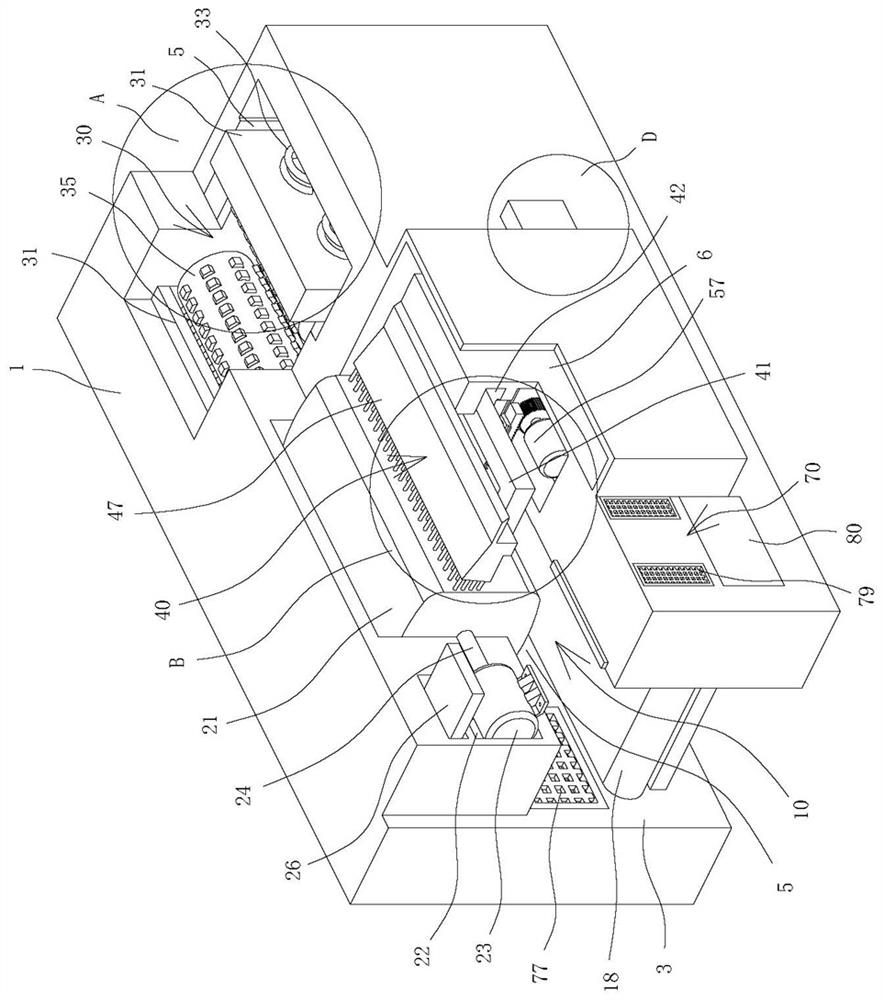

[0027] Such as Figure 1 to Figure 7 As shown, the construction waste metal separation device of the present invention comprises a frame 1, a working chamber 5 is provided in the middle of the frame 1, a feeding port 2 is provided at the upper end of the working chamber 5, a first discharge port 3 is provided at the right end of the working chamber 5, and a working chamber 5 is provided at the right end of the working chamber. 5. A separating mechanism 10 for absorbing metal is arranged in the middle, and a pulverizing mechanism 30 is arranged at 2 places of the feeding port. A dust suction mechanism 70 is provided at the discharge port 3, and the dust suction mechanism 70 is located on the right side of the separation mechanism 10.

[0028] Separation mechanism 10 comprises first motor 11, and frame 1 left end is provided with transmission chamber 12, and first motor 11 is located in transmission chamber 12, and first motor 11 front end is provided with first power shaft 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com