Cooling jacket of electric car motor

A cooling water jacket, electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of insufficient heat transfer, limit the heat dissipation efficiency of the motor, limit the output power of the motor, etc., to achieve good strength and improve heat dissipation. The effect of improving efficiency and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

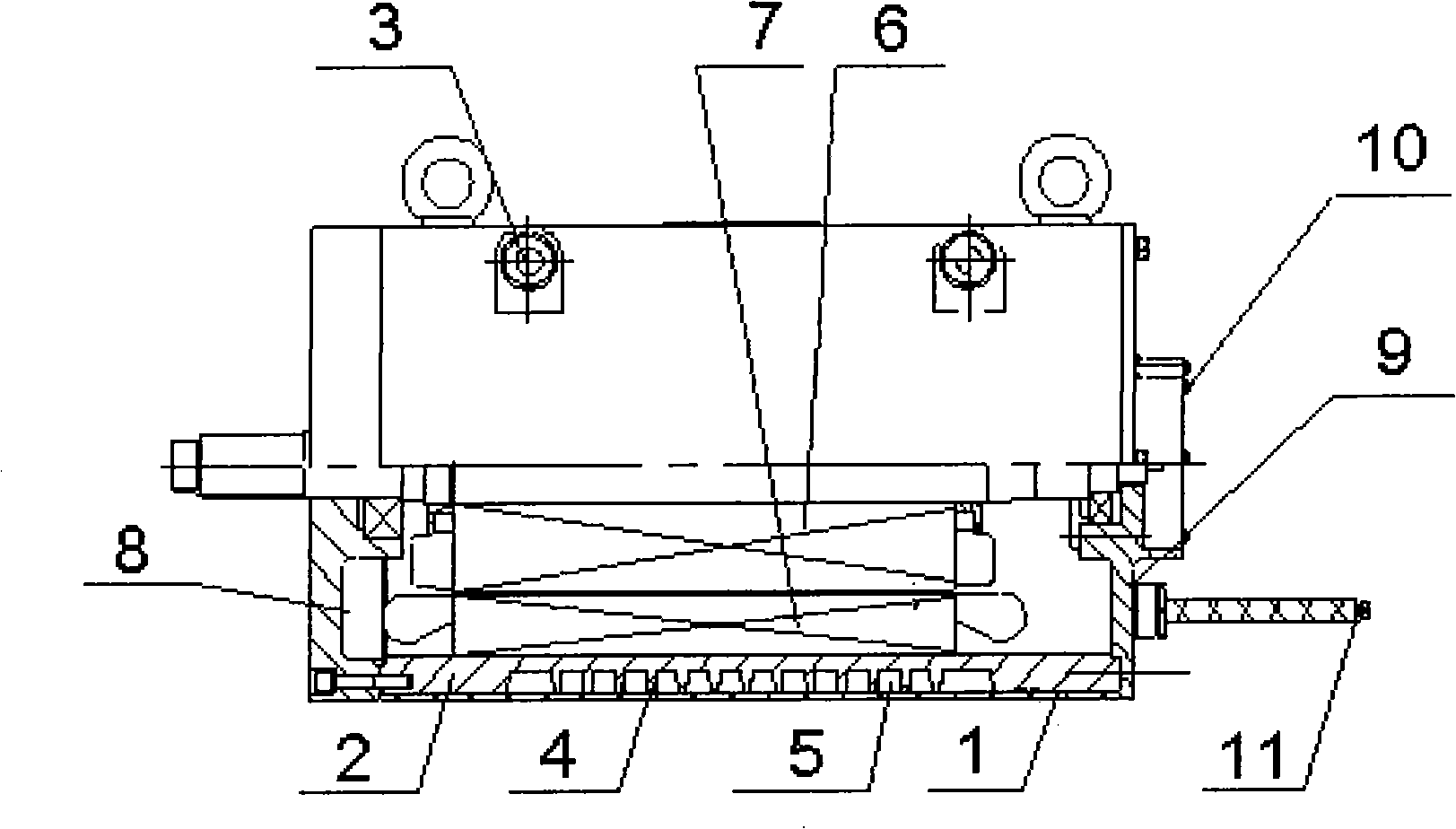

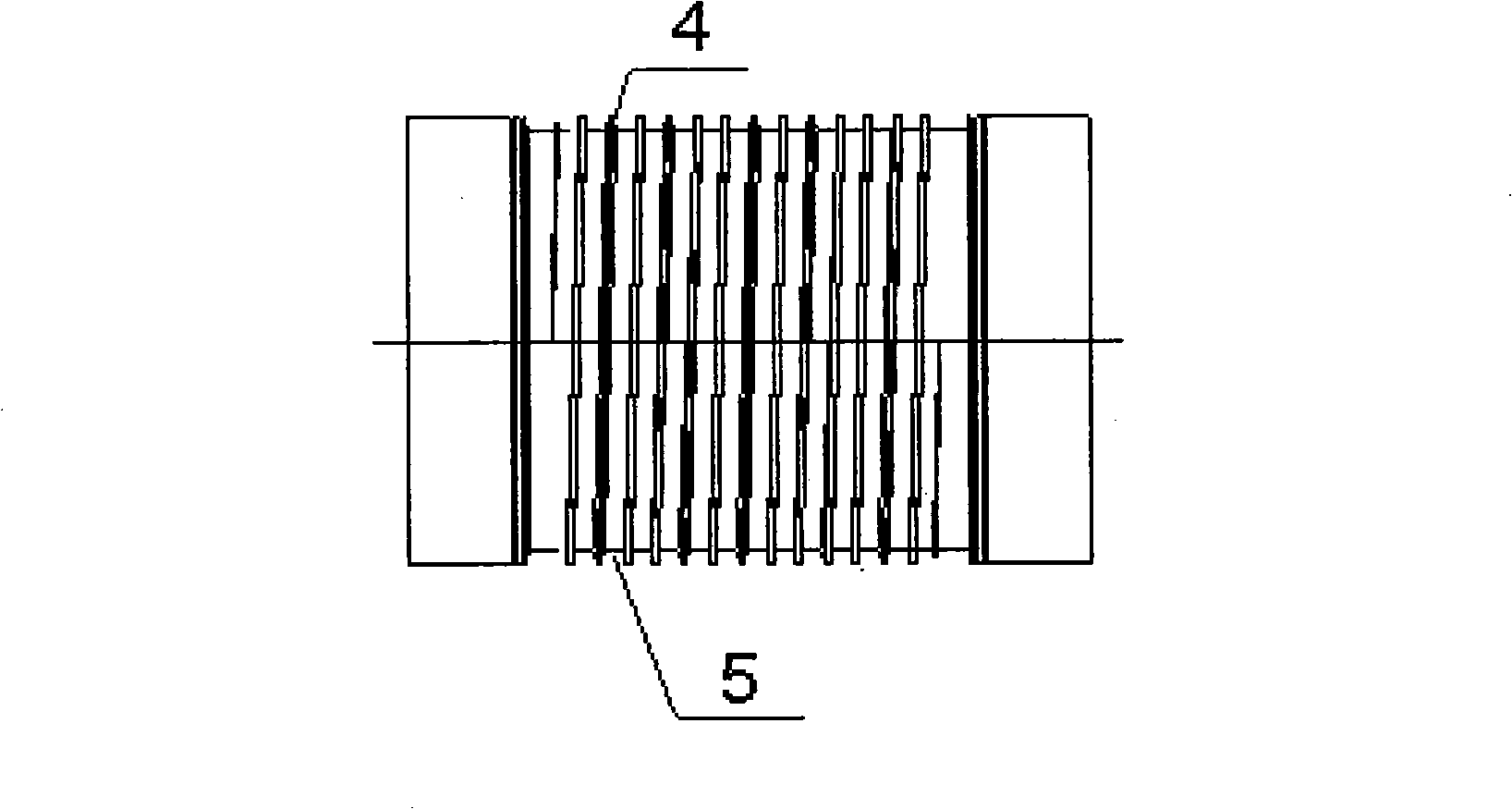

[0009] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 , figure 2 As shown, the electric vehicle motor cooling water jacket includes a double-layer structure, the outer ring shell 1 and the inner ring layer 2 of the water cooling cavity are welded into a whole, the outer ring shell 1 is provided with a cooling water pipe 3, and the inner ring layer of the water cooling cavity A spiral trapezoidal cooling rib 4 is provided on the top, forming a spiral water cavity 5 with the outer ring shell. The rotor 6 and the stator 7 are arranged in the cooling water jacket, and the front end cover 8 and the rear end cover 9 are respectively arranged at the two ends of the outer ring shell 1, and the speed sensor 10 and the lead-out cable 11 are connected to the rear end cover 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com