Production process of high-quality carbazol and anthracene

A production process and high-quality technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve problems such as small production scale, large solvent consumption, low product yield and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

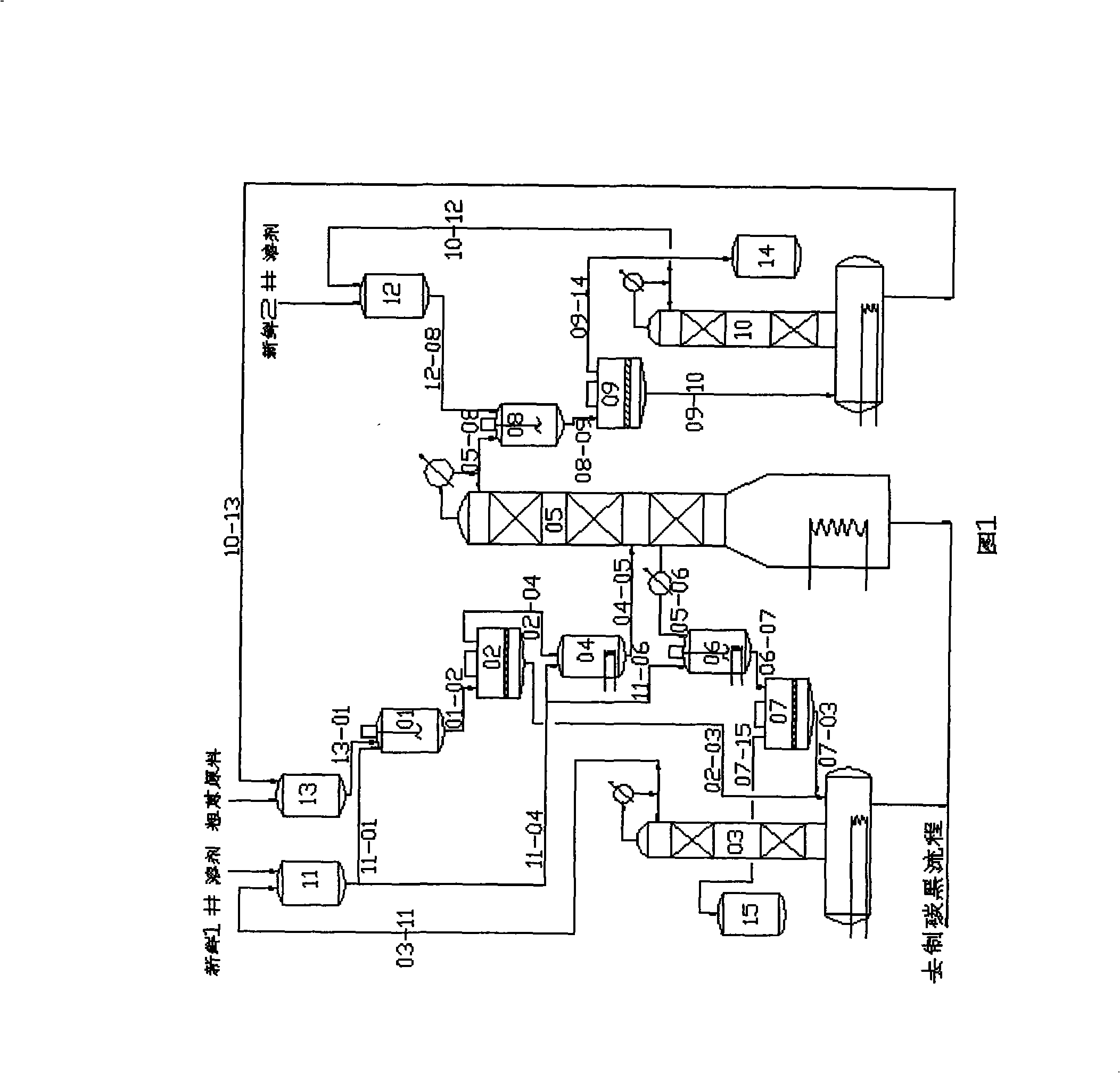

[0023] Embodiment 1: Crude anthracene processing capacity 1000kg / hr produces refined carbazole and refined anthracene

[0024]Crude anthracene raw material, which contains 28% of anthracene, 27% of phenanthrene, 14% of carbazole, about 13% of light components in total, and about 18% of derivatives and heavy components. The production device and flow process are shown in Figure 1. The crude anthracene raw material enters the raw material pre-washing tank 01 in an amount of 1000kg / hr for pre-washing. The pre-washing 1# solvent is xylene (mixed xylene, the same below), and xylene and raw material The mass ratio is 2:1, and the washing is carried out at 28°C under normal pressure. After stirring for 10 minutes, the solid-liquid mixture in the raw material washing tank 01 is transported to the automatic centrifuge 02 for solid-liquid separation, and the rotation speed is 6000r / min. The solid phase obtained by separation is the filter residue, and its components are carbazole, anthr...

Embodiment 2

[0026] Embodiment 2: crude anthracene processing capacity 1000kg / hr produces refined carbazole and refined anthracene

[0027] Crude anthracene raw material, which contains 28% of anthracene, 27% of phenanthrene, 14% of carbazole, about 13% of light components in total, and about 18% of derivatives and heavy components. The production equipment and process are shown in Figure 1. The crude anthracene raw material enters the raw material pre-washing tank 01 at a rate of 1000kg / hr for pre-washing. The pre-washing 1# solvent is 200# solvent oil, and the mass ratio of solvent to raw material is 2.5:1 , the washing is carried out at 28°C under normal pressure, and after stirring for 10 minutes, the solid-liquid mixture in the raw material washing tank 01 is transported to the automatic centrifuge 02 for solid-liquid separation at a speed of 5500r / min, and the solid phase obtained from the separation is the filter residue , the components are carbazole, anthracene, a small amount of ...

Embodiment 3

[0029] Embodiment 3: crude anthracene processing capacity 1100kg / hr produces refined carbazole and refined anthracene

[0030] The crude anthracene raw material contains 26% of anthracene, 28% of phenanthrene, 12% of carbazole, about 12% of light components in total, and about 24% of derivatives and heavy components. The production device and process are shown in Figure 1. The crude anthracene raw material enters the raw material pre-washing tank 01 at an amount of 1100kg / hr for pre-washing. The pre-washing 1# solvent is trimethylbenzene, and the mass ratio of the solvent to the raw material is 2.5:1. It is carried out under normal pressure at 28°C. After stirring for 10 minutes, the solid-liquid mixture in the raw material washing tank 01 is transported to the automatic centrifuge 02 for solid-liquid separation at a speed of 6500r / min. The solid phase obtained from the separation is the filter residue. It is divided into carbazole, anthracene, a small amount of phenanthrene, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com