Conveyor belt self-adapting adjusting apparatus of belt conveyor

A belt conveyor, self-adaptive adjustment technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of excessively dense roller setting spacing, strong operating experience, conveyor belt cuts, etc., to prevent Conveyor belt drum or lateral discount, wide application range and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

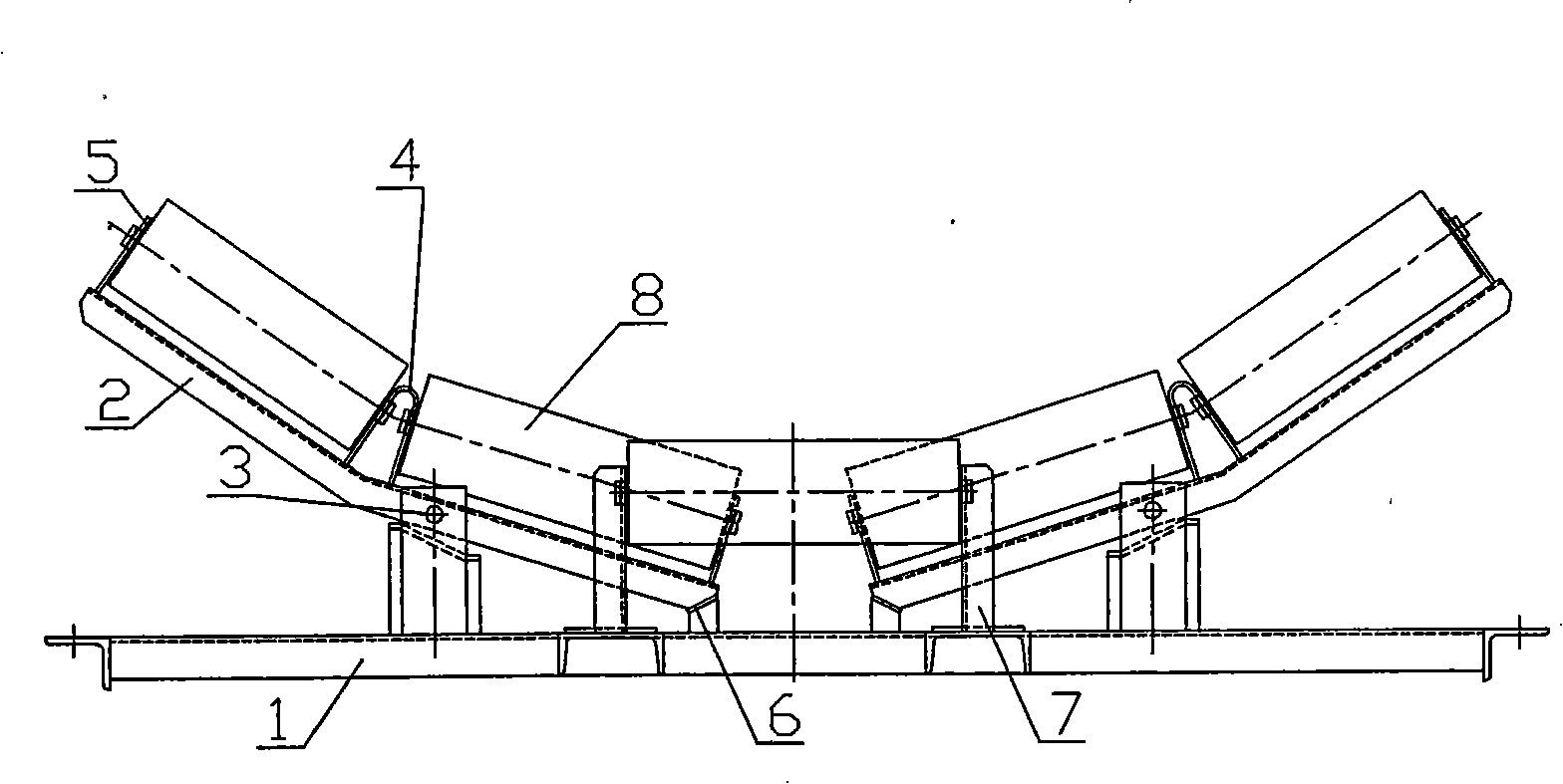

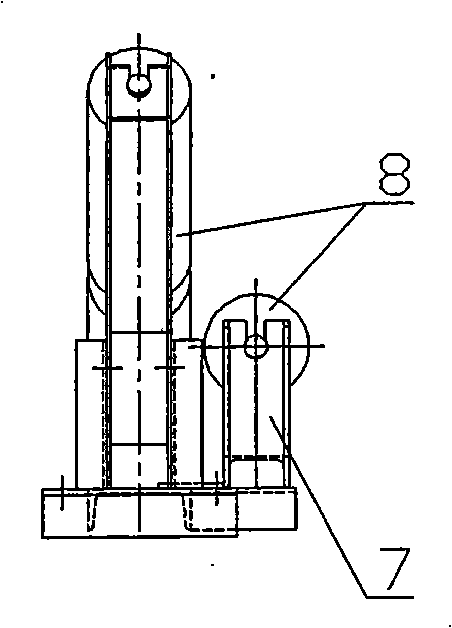

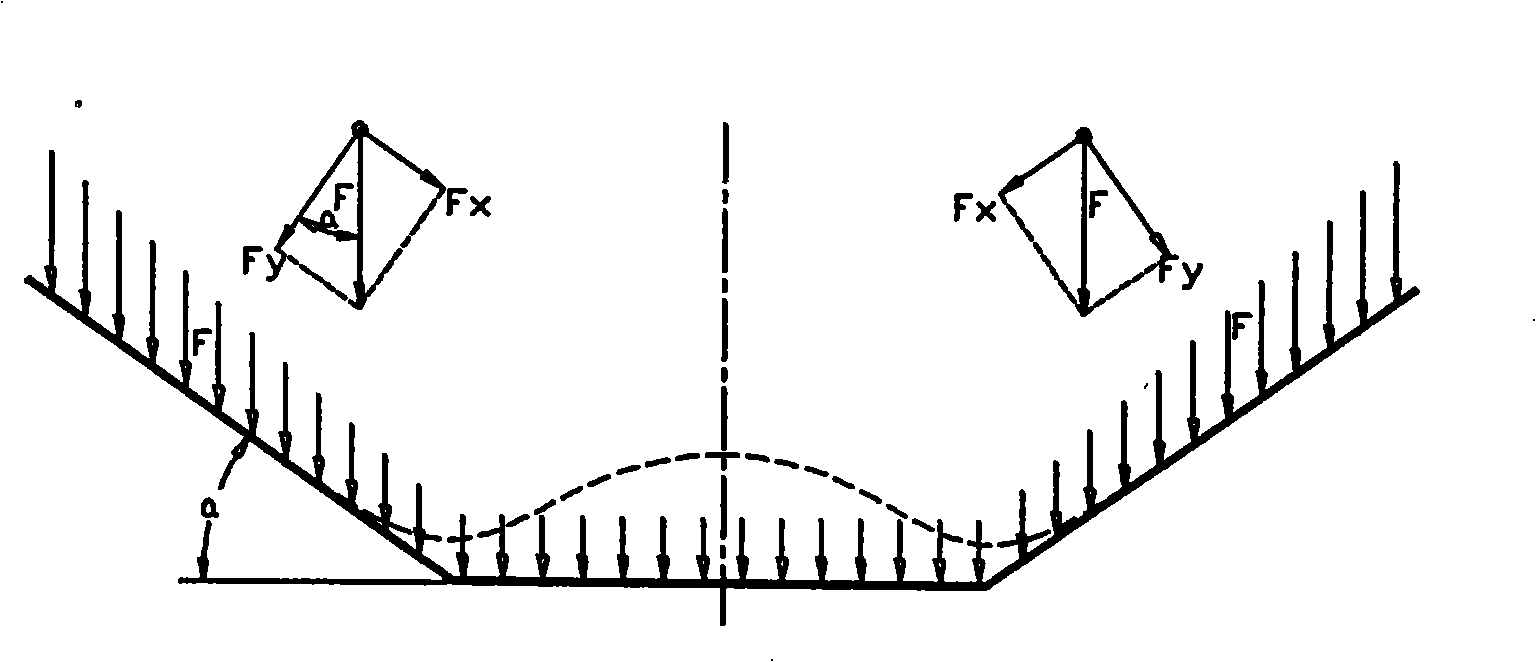

[0020] Such as figure 1 , figure 2 As shown, a belt conveyor belt self-adaptive adjustment device is characterized in that it is provided with a beam 1 parallel and fixedly connected to the belt conveyor frame, and two V-shaped swing roller brackets are correspondingly arranged on the left and right sides of the beam 1 2. The swing roller bracket 2 and the beam 1 are coaxially hinged through the connecting shaft 3; in practice, the beam 1 is used to be fixed on the belt conveyor frame as the swing roller bracket 2, the fixed roller bracket 7 and the roller 8 the carrier. The swing idler bracket 2 is provided with a connecting shaft 3 near the lower part of the middle, and the swing idler bracket 2 is coaxially hinged with the beam 1 . The middle part of each swing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com