Device for measuring temperature of hot-rolled strip steel

A technology for temperature measurement and hot-rolled strip steel, which is applied to length measuring devices, temperature measurement of moving solids, metal rolling, etc. Simple, good craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

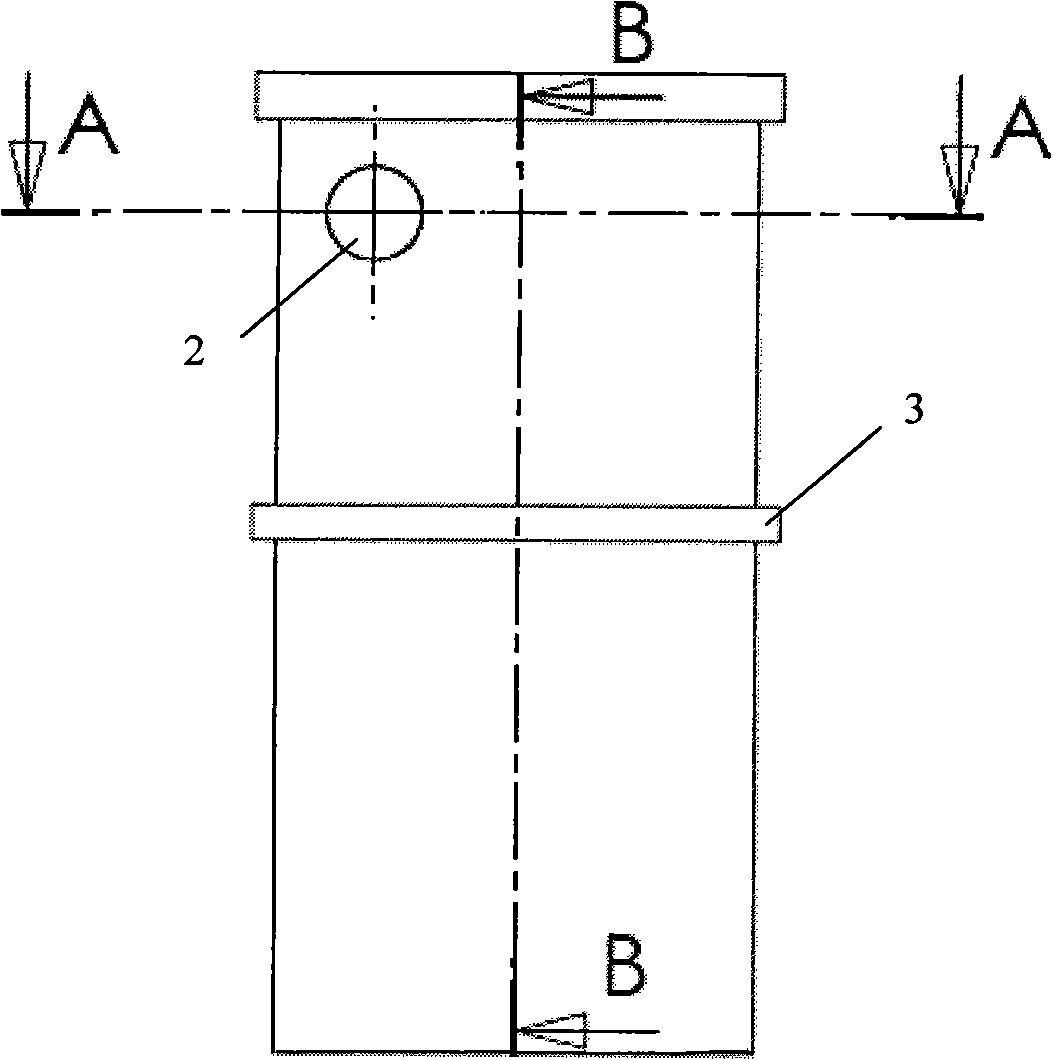

[0019] Such as figure 1 , figure 2 ,, image 3 , Figure 5 As shown, the present invention includes a measurement chamber 8, a nozzle 1 and a non-contact temperature sensing element 6; a nozzle boss 3 is arranged on the outer cylindrical surface of the nozzle 1, and a nozzle top partition 4 is installed on the top surface of the nozzle 1, and the nozzle air intake The port 2 is arranged tangentially along the circumference, and the measuring chamber air inlet 7 is opened on the lower cylindrical surface of the measuring chamber 8. The nozzle 1 is installed in the lower part of the measuring chamber 8, and the nozzle boss 3 and the nozzle top partition 4 form a sliding movement with the measuring chamber 8. Cooperate, the air inlet 7 of the measurement chamber is located between the nozzle boss 3 and the nozzle top partition 4, the measurement chamber 8 above the nozzle top partition 4 is equipped with a non-contact temperature measurement sensing element 6, the air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com