Wire connector

A technology of connectors and wires, which is applied in the field of electronic equipment, can solve problems such as difficult processing and installation, short circuits, and time-consuming, and achieve the effects of reducing labor costs and time, improving work efficiency, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

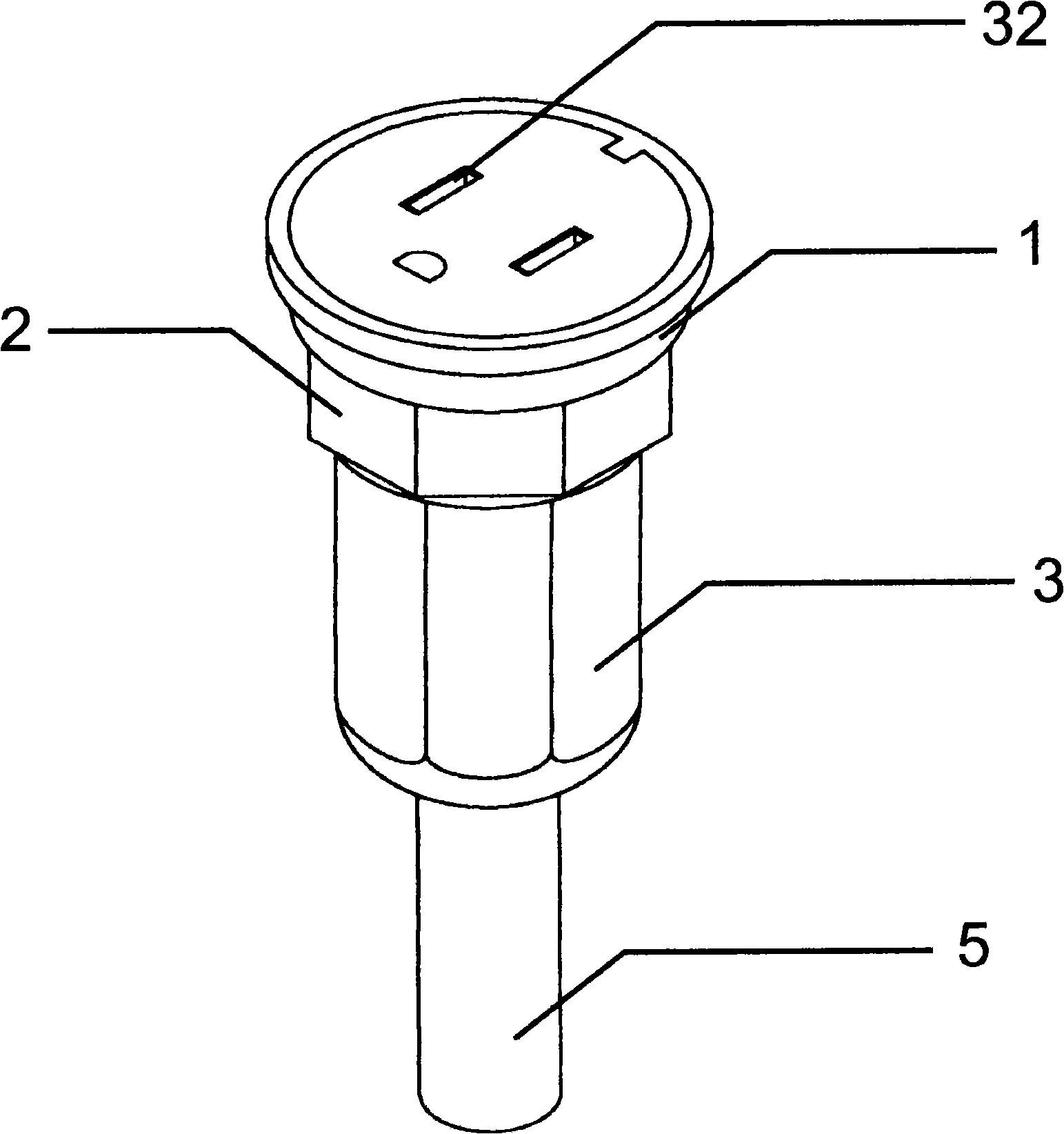

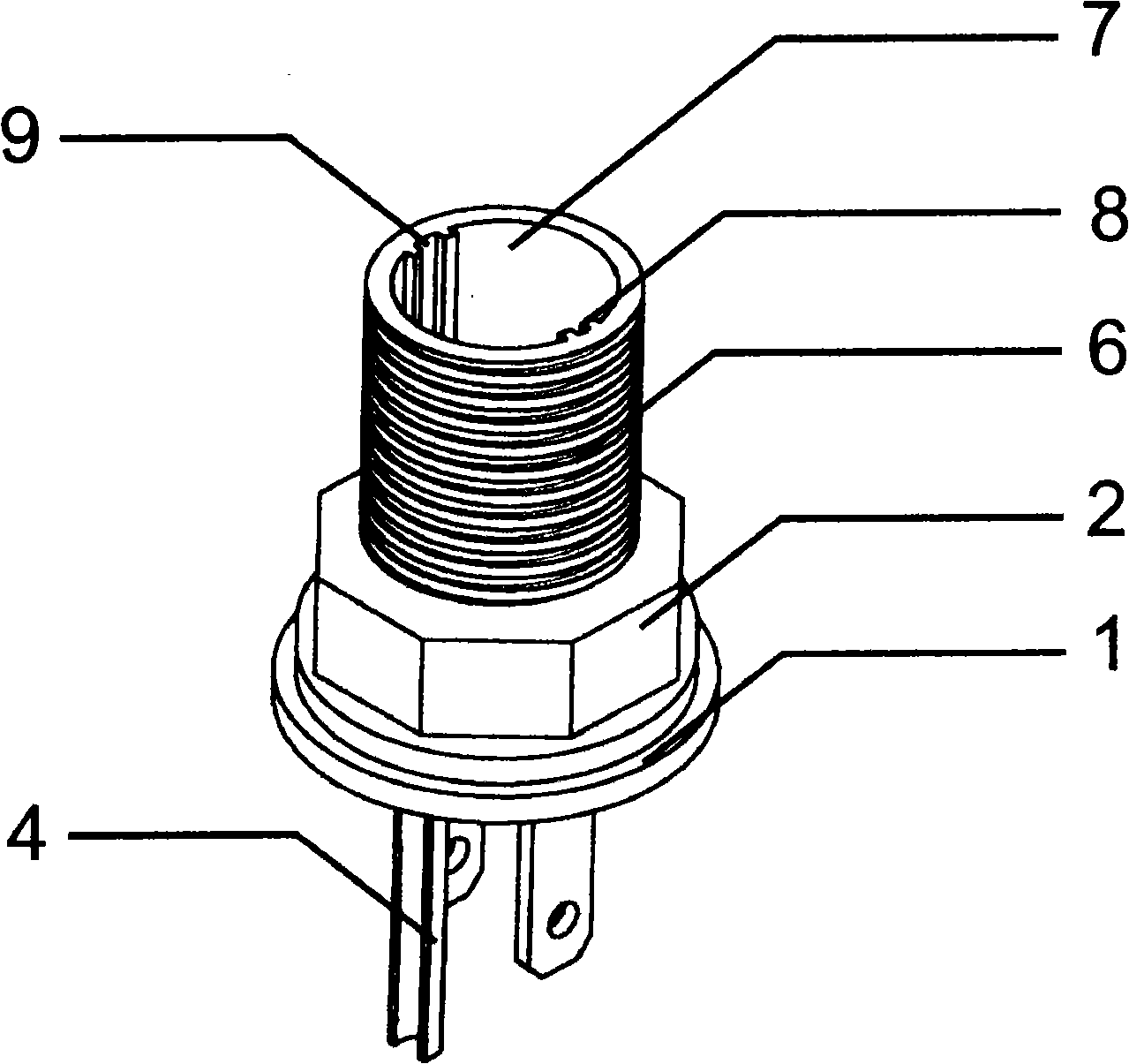

[0064] An electric wire connector provided by the present invention is composed of a connector body (31), a fixing aid (15), and an insertion aid (16), such as figure 1 , 2 , 3, 4, 5, 6, and 7, it is characterized in that the connector body (31) is composed of a plug body (1), a socket body (2) and a shell back cover (3), wherein the plug body (1) is A conductive insert hole (32) is left, and several conductive inserts (4) are provided for docking with the power supply. The other end of the plug body (1) is connected to the socket body (2), and the socket body (2) opposite to the plug body (1) is provided with a docking seat (10), and there are several pointed strips on the docking seat (10) shaped metal butt rod (11). The socket body (2) is connected with a hollow cylinder, the surface of the hollow cylinder is provided with a socket thread (6), and the inner wall of the shell back cover (3) is also provided with a back cover thread (13), and through the surface of the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com