Energy-saving electromagnet

A technology of electromagnets and iron plates, applied in the direction of electromagnets, etc., can solve problems such as the shortage of copper wire resources, affect the reaction speed, pollution, etc., achieve the effects of improving ventilation and heat dissipation conditions, solving slow movement speed, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

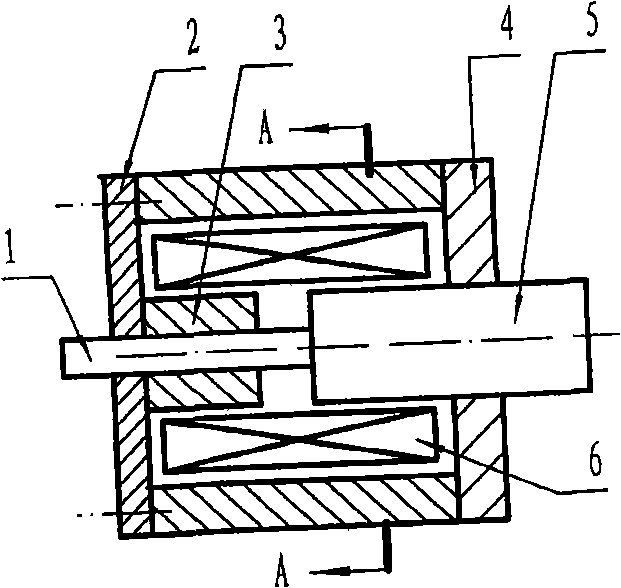

[0022] Embodiment 1 (see figure 1 , 2 ):

[0023] Depend on figure 1 , 2 It can be seen from the shown embodiment 1 that it includes a coil 6, an armature 5, a forehead iron 3, an upper cover 4, and a bottom plate 2; the characteristic is that the material of the coil 6 is aluminum wire.

[0024] The material of the upper cover 4 and the bottom plate 2 is iron plate.

[0025] The housing is a first circular tubular housing 7 with an axial through-slot hole 8, one end of the first circular tubular housing 7 is welded to the upper cover 4, and the other end is fixedly connected to the bottom plate 2 with screws ; The material of the first circular tubular shell 7 is iron pipe.

[0026] exist figure 1 Middle 1 is a push rod, and 9 is a mounting hole located on the base plate 2.

Embodiment 2

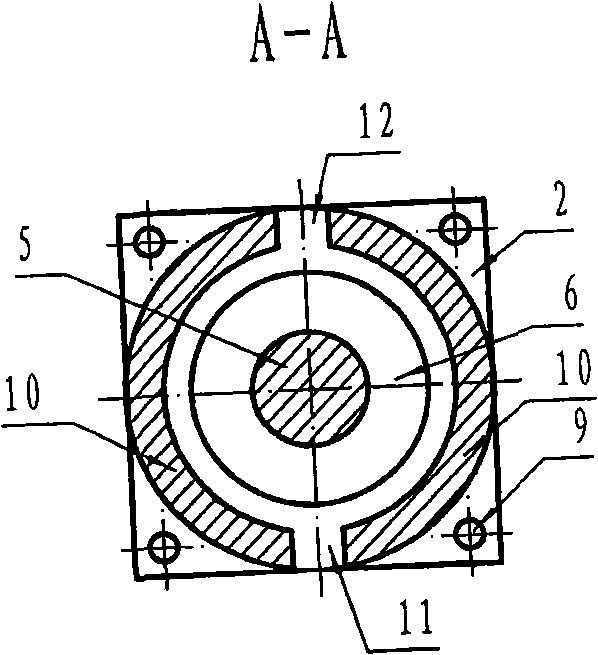

[0027] Embodiment 2 (see figure 1 , 3 ):

[0028] The difference between Embodiment 2 and Embodiment 1 is that the housing is a second circular tubular housing 10 with a pair of symmetrical axial through-slot holes 11 and 12 composed of two semicircular tubes. One end of the casing 10 is welded to the upper cover 4 , and the other end is fixedly connected to the bottom plate 2 with screws; the material of the second circular tubular casing 10 is iron pipe.

Embodiment 3

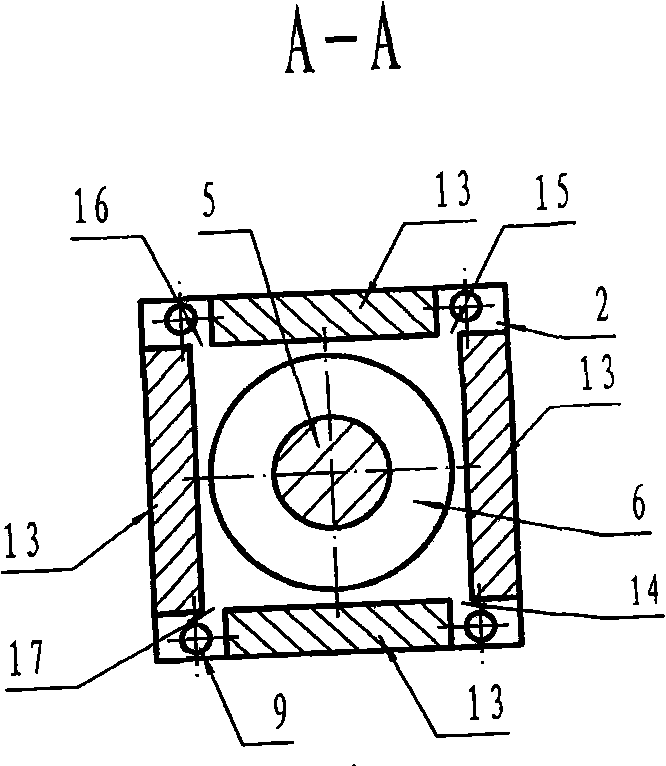

[0029] Embodiment 3 (see figure 1 , 4 ):

[0030] The difference between embodiment 3 and embodiment 1 is that the housing is a square tubular housing 13 composed of four iron plates, and the four edges of the square tubular housing 13 are respectively provided with first and second , the 3rd, the 4th gap 14,15,16,17, promptly be provided with gap between the adjacent sides of described four iron plates; One end of described four iron plates is welded with loam cake 4, and their other One end is respectively fixedly connected with the bottom plate 2 with screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com