Lever type pneumatic pressurizing cradle

A pneumatic pressurization and lever-type technology, which is applied in the direction of textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problem of inaccurate upper roller bearing axial centering limit, imperfect spinning supporting functions, and working pressure. Problems such as inconsistency in direction can be solved to achieve the effect of consistent part size, improved stress condition, and stable assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

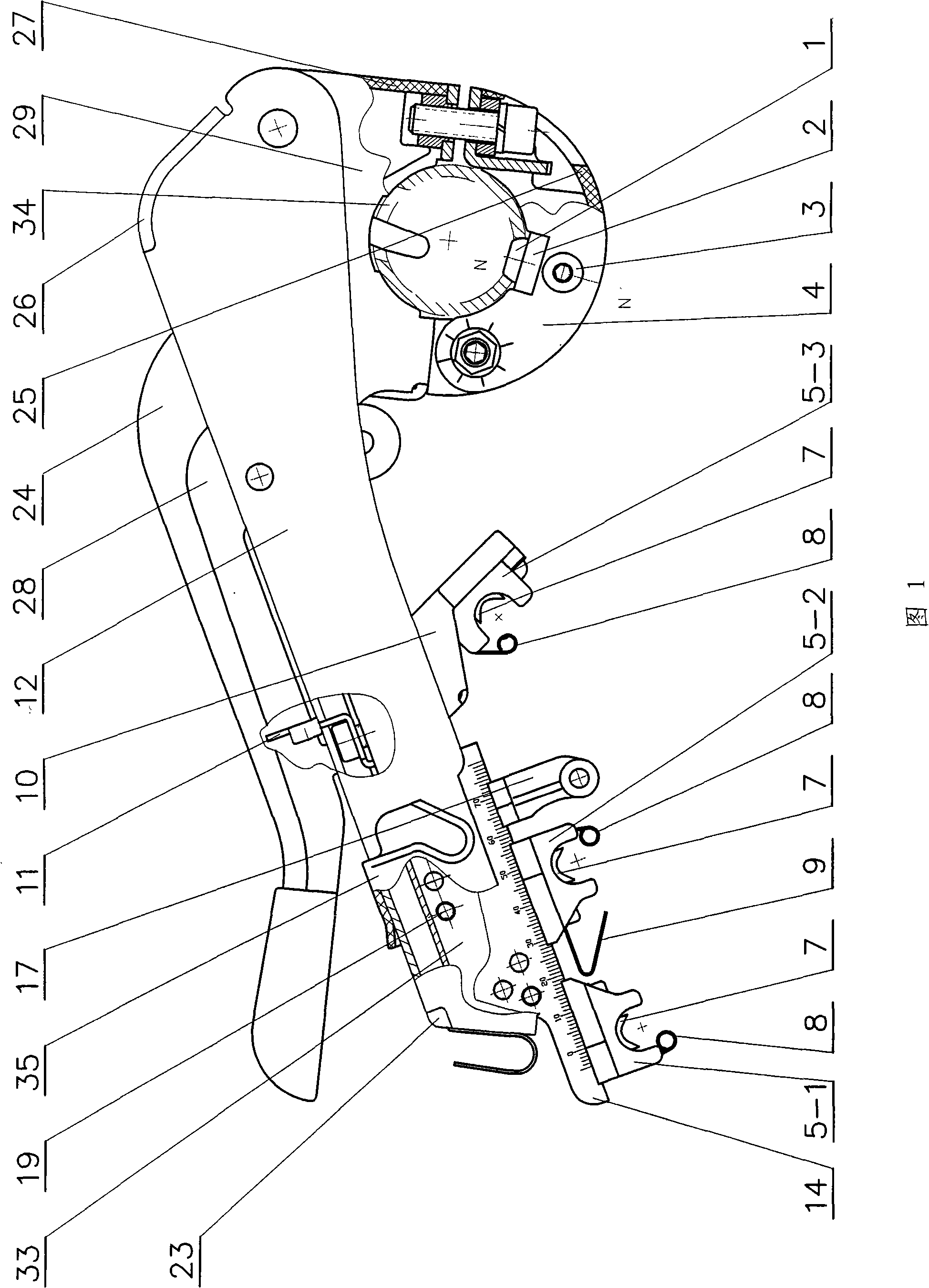

[0030] The structure of the lever type pneumatic pressurized cradle of the present invention will be further described below in conjunction with the accompanying drawings.

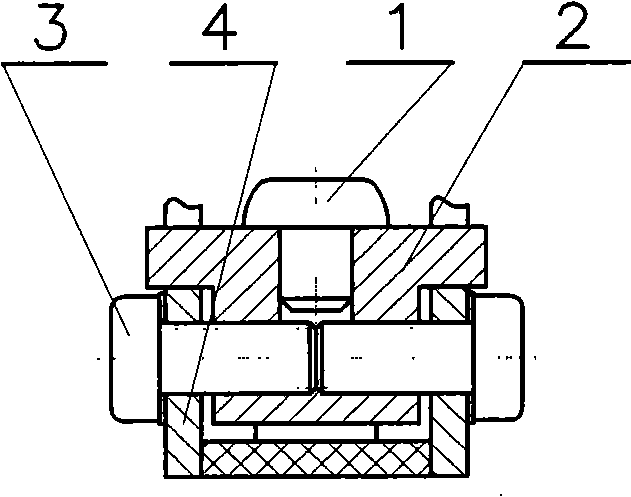

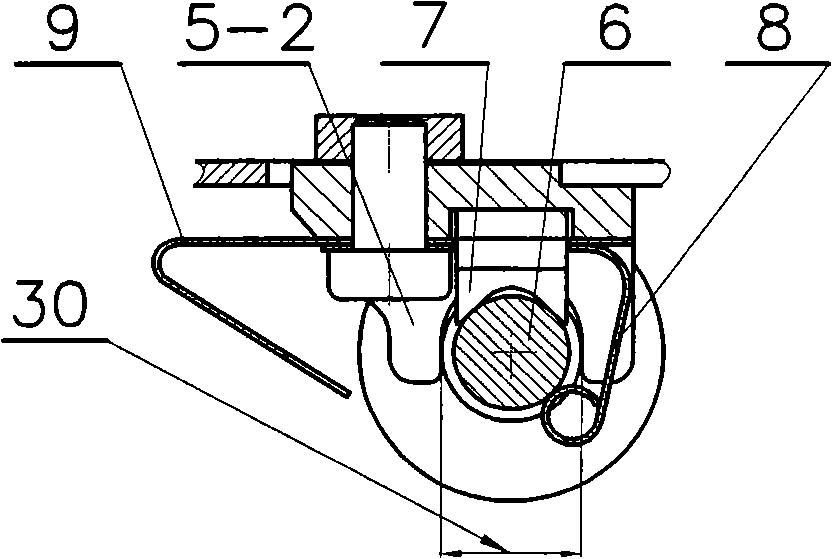

[0031] As shown in Figure 1, the lever-type pneumatic pressurized cradle in this embodiment includes a housing 12, a groove seat 33 hinged with the housing through a pin 19, and an adjustment seat 14 hinged with the groove seat, fixed on the groove seat The rear roller seat 10 on the top, the front bearing seat 5-1 and the middle bearing seat 5-2 installed on the adjustment seat, the rear bearing seat 5-3 installed on the rear roller seat, the handle 28 hinged with the housing and Upper deck 29, one end is hinged with the upper deck, the lower deck 4 that one end is threadedly connected with the upper deck, the holding tube 34 that is equipped with an air bag clamped by the upper deck 29 and the lower deck 4; The overall shape is arc-shaped and streamlined, using plastic fasteners I23, plastic fasteners II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com