Liquid container, sealing method, manufacturing method and reproducing method thereof, and reproducing liquid container

A liquid container and liquid technology, which can be used in printing, thin material processing, transportation and packaging, etc., and can solve the problems of ink composition changes and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

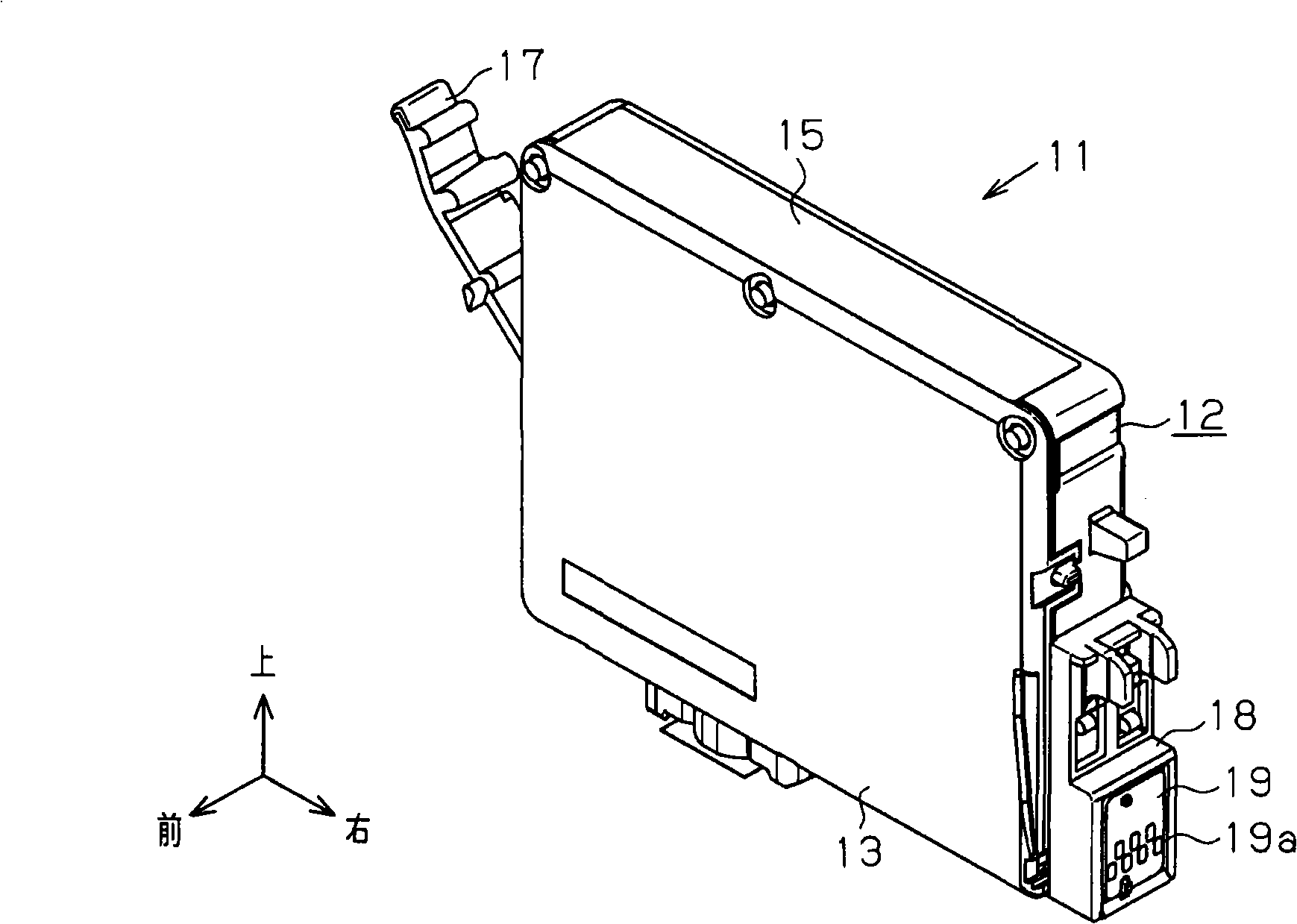

[0031] Below, according to Figure 1 ~ Figure 1 2. One embodiment of the present invention will be described. In the descriptions of this manual, the terms "front-back direction", "left-right direction", "up-down direction" and Figure 1 ~ Figure 4 Corresponds to the arrows in .

[0032] Such as Figure 1 ~ Figure 4 As shown, the ink cartridge 11 as a liquid container in a new product state has, for example, a flat substantially rectangular parallelepiped container body 12 made of a polyolefin (PO)-based resin material such as polypropylene (PP). Such as Figure 4 As shown, an opening 12a is formed on the front surface of the container main body 12, and a film member (not shown) made of a heat-weldable material is attached to the container main body 12 to cover almost the entire surface of the opening 12a, and A cover body 13 is detachably attached from the outside (front side) of the membrane member to conceal the opening 12a. In addition, a film member 14 made of a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com