A method of manufacturing a structure

A mask, gold layer technology, applied in the field of manufacturing microelectronic devices with this structure, can solve the problems of limiting micro-contact printing, harmfulness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

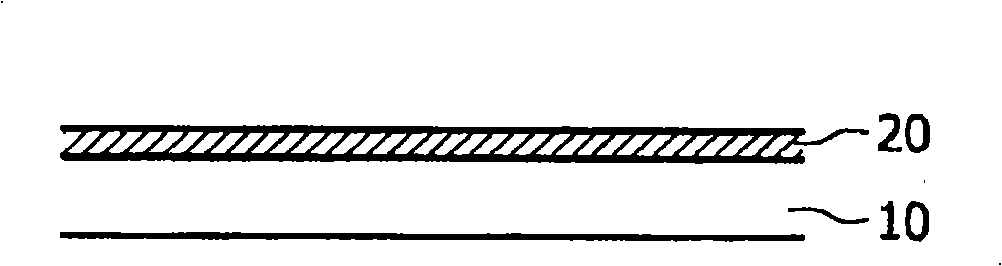

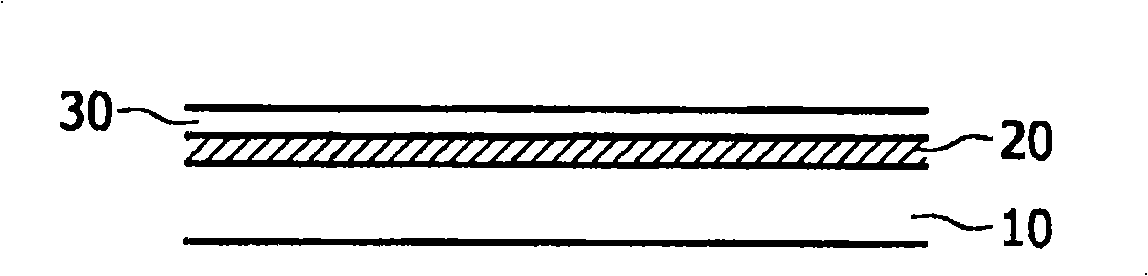

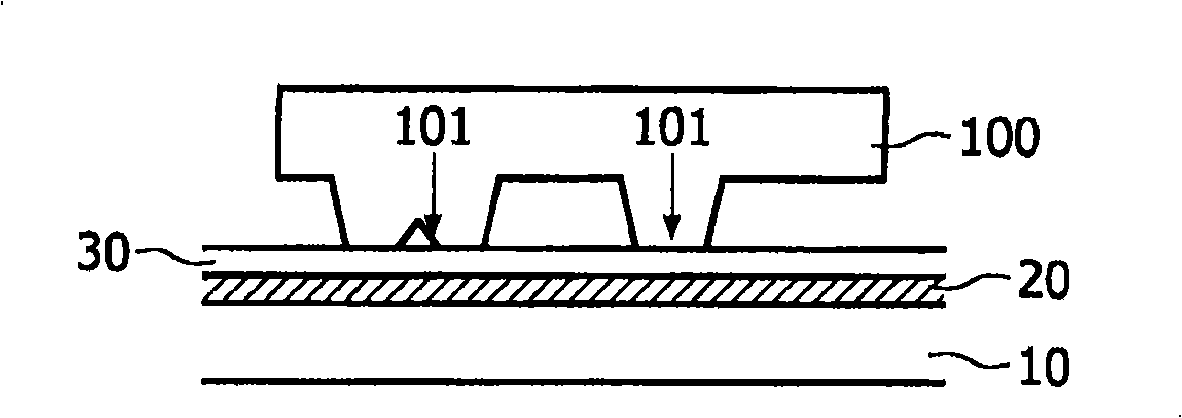

[0028] Figure 1 shows the six stages in a first embodiment of the method of the invention in cross-sectional view. Microcontact printing was used in this example for the patterning of the gold oxide layer. Therefore, patterning occurs after oxidation. More details are given in Examples 1-7.

[0029] Figure 1A A substrate 10 is shown with a gold layer 20 thereon. The substrate is a silicon substrate. The substrate has been thermally oxidized and provided with a Ti adhesion layer. Thereafter, the gold oxide layer 30 is provided by oxidizing the gold layer 20 in a plasma treatment ( Figure 1B ). Then, the gold oxide layer 30 is patterned using the stamp 100 ( Figure 1C). A stamp 100 suitable for microcontact printing has a stamp surface 101 conforming to a desired pattern. As is known to those skilled in the art, such a stamp is suitably fabricated from PDMS and any ink is provided to the stamp 100 prior to embossing. The ink includes a solvent with an active componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com