Dust boot with grease channel

A technology of lubricating oil channel and dust cover, applied in the field of ball and socket joints, to reduce the risk of pollution and the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

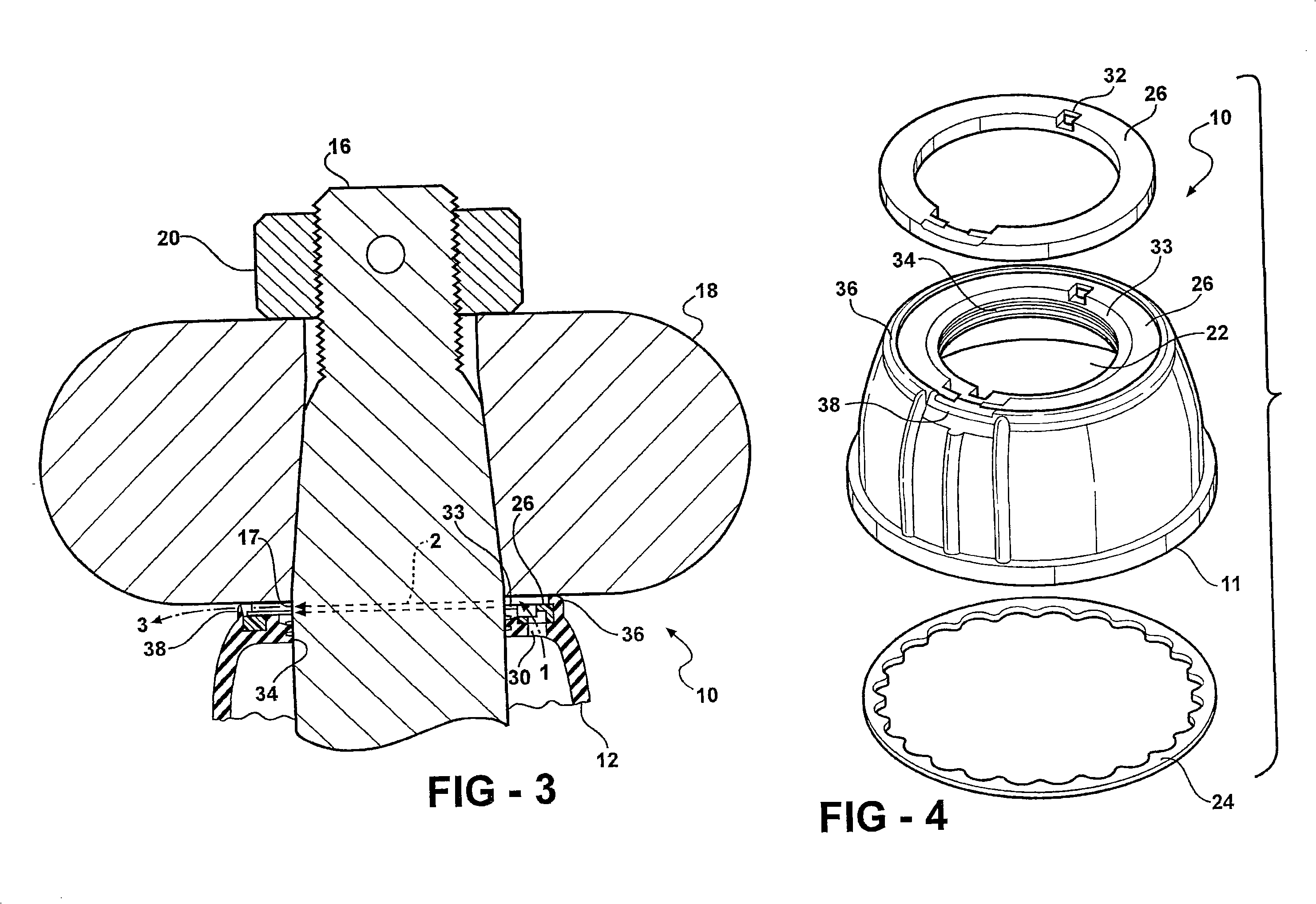

[0025] Referring to FIGS. 1-8C , the dust cover 10 of the present invention is roughly as shown in FIGS. 1 and 2 . The dust cover 10 is a highly resilient device, typically molded into a domed or convoluted shape. The dust cover may take other shapes than domes, including stepped or capped cylinders, accordion folds, or variations of other known shapes. The dust cover 10 is generally made of elastic body such as natural or artificial rubber or various plastics. Choose a material that deforms without appreciable resistance, but whose inherent elasticity tends to return it to its original molded shape after deformation.

[0026] In this embodiment, the body of the dust cover 10 is dome-shaped and includes a large orifice 12 or mounting hole 12 at the housing end 13 having a lip 11 or other suitable for coupling with the joint housing. The structure that the bolt outlet end 19 of 14 tightly fits. The large hole 12 and lip 11 of the dust cover 10 may be reinforced with a rigid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com