Fiber-reinforced composite resin composition, and adhesive and sealing agent

A fiber-reinforced composite and resin composition technology, applied in fiber-reinforced composite resin compositions for adhesives or fillers, high-transparency sealants, adhesives and sealants, can solve the problem of unclear thermal conductivity , without considering the use of sealants, adhesives or fillers, etc., to achieve the effect of small linear thermal expansion coefficient

Inactive Publication Date: 2008-10-29

ROHM CO LTD +2

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the fiber-reinforced composite material in JP-A-2005-60680 does not consider use as a sealant, adhesive or filler.

In addition, the thermal conductivity in the in-plane direction (board surface direction) of this fiber-reinforced composite material shows a high thermal conductivity of, for example, 1 W / m·K, but the thermal conductivity in the direction perpendicular to it has not been clarified.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

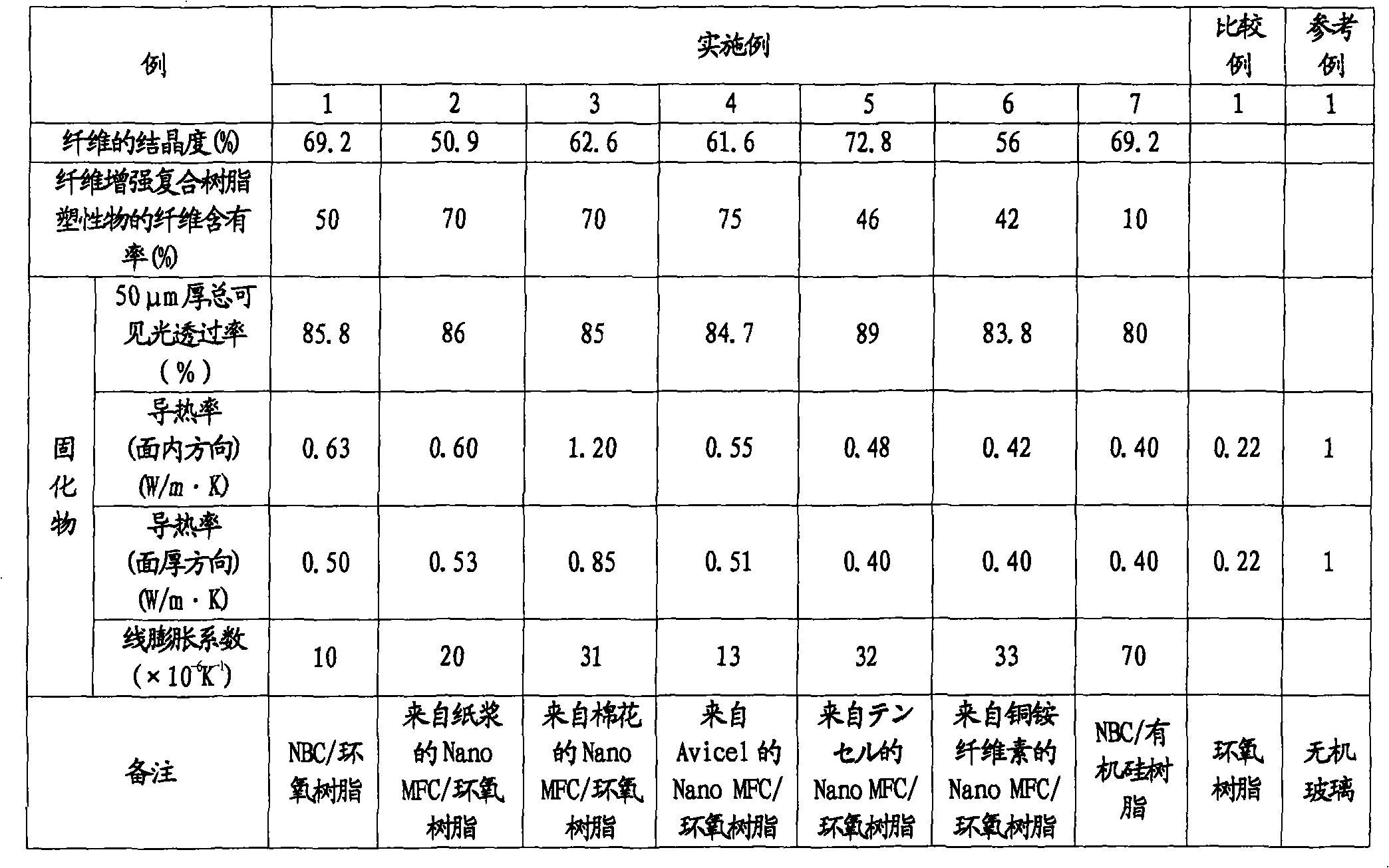

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

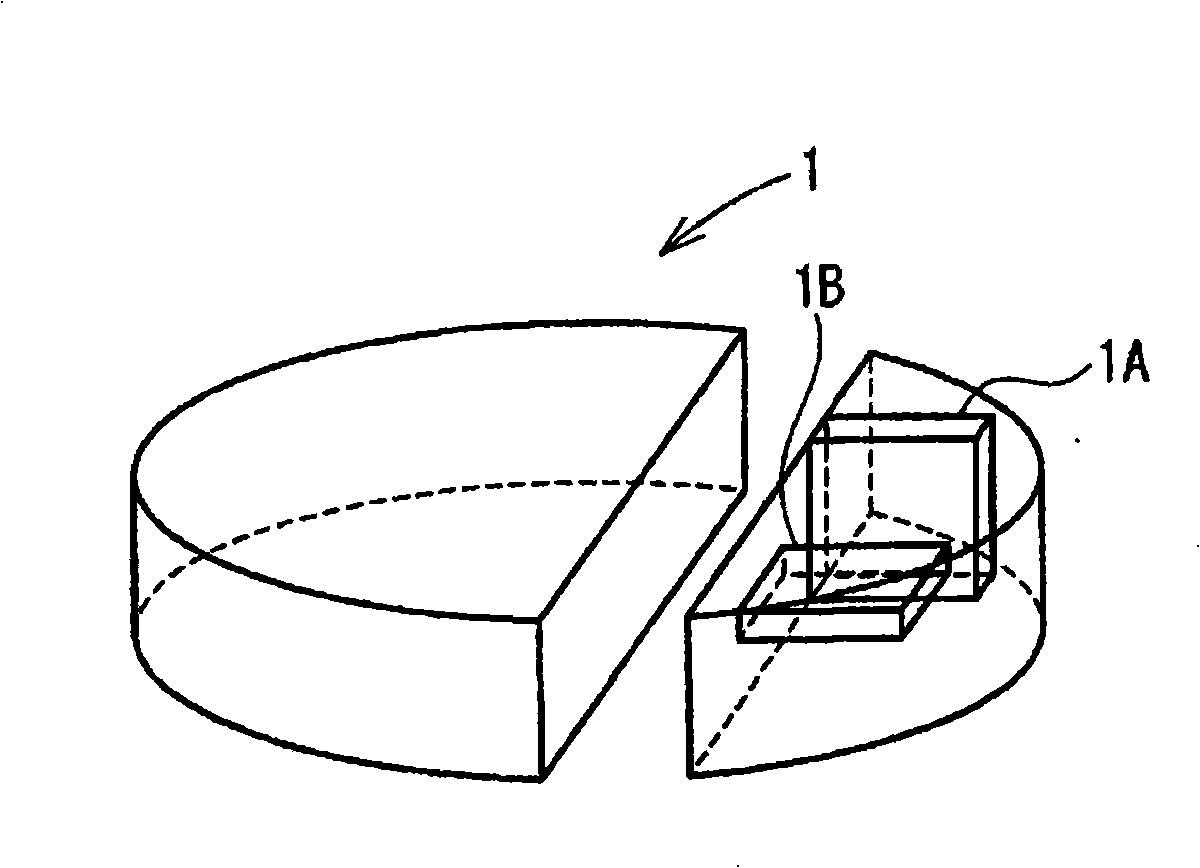

Disclosed is a fiber-reinforced composite resin composition which can be used as a sealing agent, an adhesive or a filler, specifically a fiber-reinforced composite resin composition which has low thermal expansion, high strength light weight and high thermal conductivity at such levels that have been required recently, particularly which has a high isotropic thermal conductivity at a satisfactory level. The composition comprises a fiber having an average fiber diameter of 4 to 200 nm. When the composition is cured in a plate-like shape, the cured product has a total light transmittance of 70% or higher per 50 [mu]m thickness as measured at an wavelength of 400 to 700 nm and thermal conductivities both in a thickness-wise direction and a plane-wise direction of 0.4 W / m. K or higher. In the cured product, the fiber is oriented randomly.

Description

Fiber reinforced composite resin composition and adhesive and sealant technical field The present invention relates to a fiber-reinforced composite resin composition used as a sealant, an adhesive, or a filler. Specifically, it relates to a highly transparent sealant, adhesive, or A fiber-reinforced composite resin composition for a filler. The present invention also relates to adhesives and sealants formed using the fiber-reinforced composite resin composition. Background technique Resin compositions used as sealants, adhesives, and fillers may require high transparency, low thermal expansion, high strength, light weight, and high thermal conductivity due to their use and characteristics of cured products. Wait. For example, sealing materials for LEDs are required to be highly transparent to transmit light from phosphors, and to ensure dimensional stability, durability, and light weight of products in the use environment, small thermal expansion coefficients and high st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L101/00C08K7/02C08L1/00C09J101/00C09J201/00

CPCC08J5/045C08K3/0033C08K7/02C08L1/02C08L63/00C08L83/00C09J101/02C08K3/013C08L2666/14C08L2666/02

Inventor 矢野浩之能木雅也伊福伸介阿部贤太郎竹泽由高半田敬信

Owner ROHM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com