Light source module group with excellent heat dispersion performance

A technology of light source module and heat dissipation performance, which is applied in the direction of light source, point light source, circuit heat device, etc., can solve the problems of unsatisfactory thermal conductivity, thermal damage, and heat can not be effectively eliminated, and achieve the purpose of overcoming poor thermal conductivity Good, good heat dissipation effect, large thermal contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

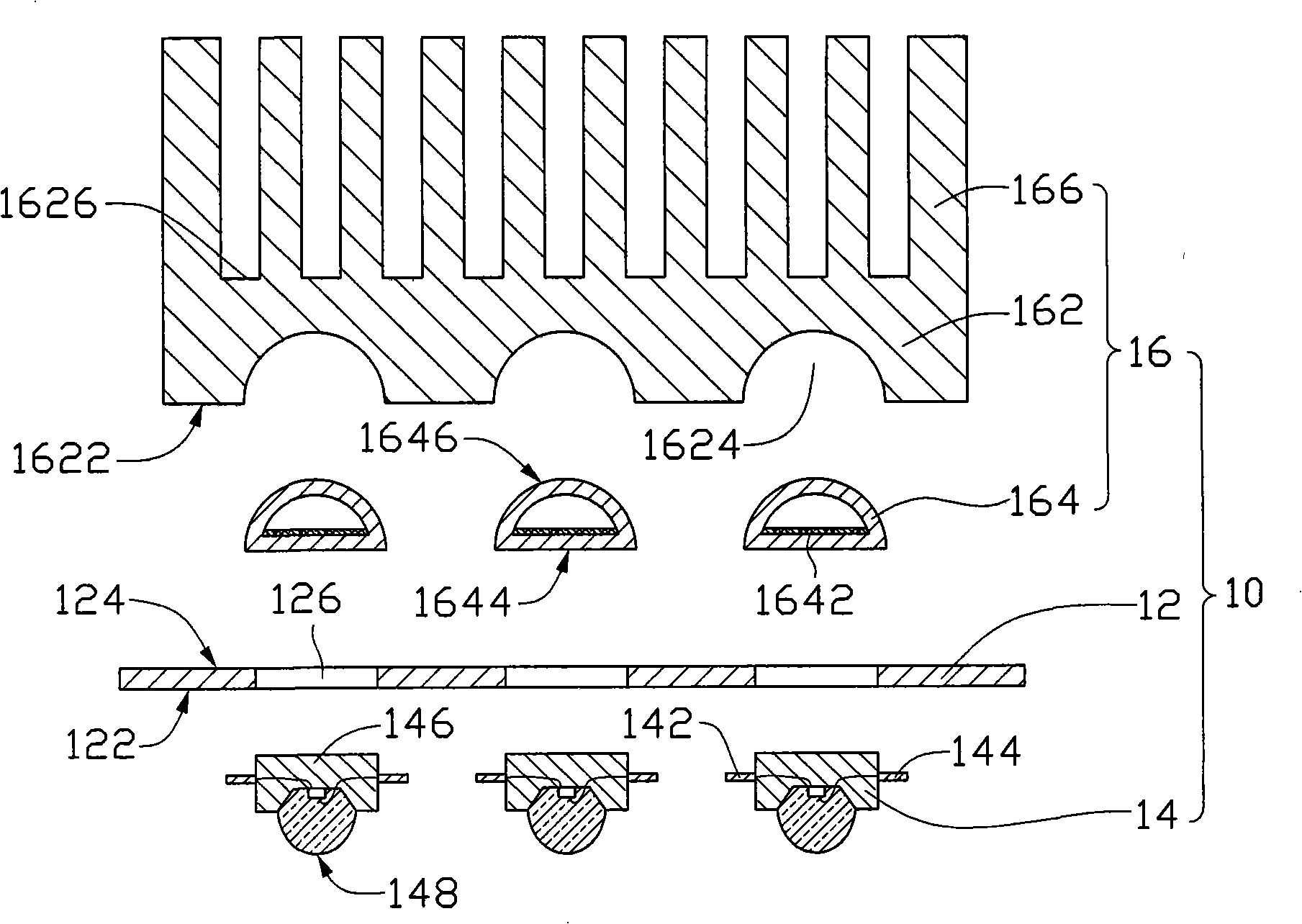

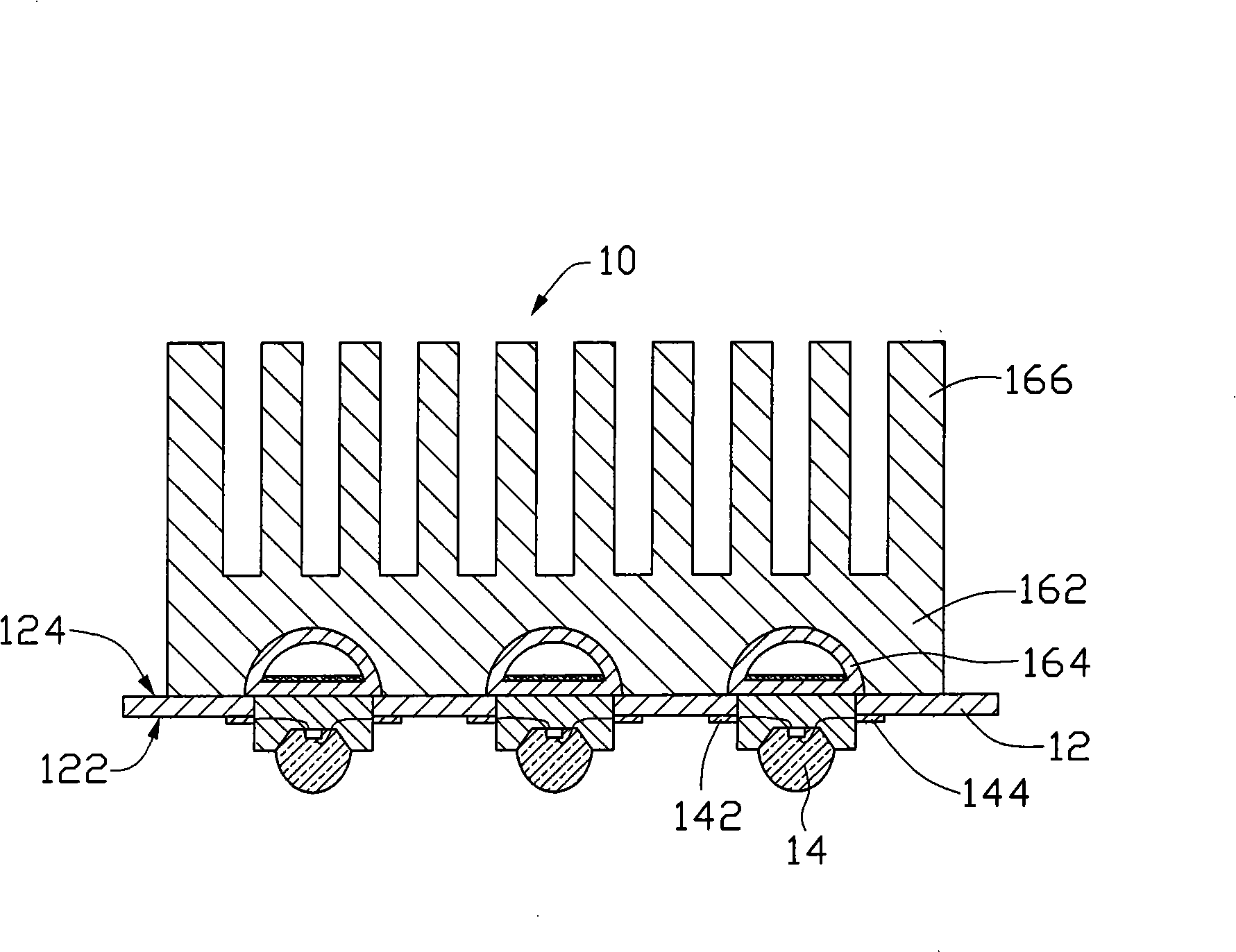

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] see figure 2 and image 3 , the light source module 10 with good heat dissipation performance provided by the embodiment of the present invention includes: a printed circuit board 12 , a plurality of light emitting elements 14 and a heat dissipation element 16 . The heat dissipation element 16 includes a base 162 , a plurality of heat conducting elements 164 and a plurality of heat dissipation fins 166 .

[0014] The printed circuit board 12 includes a first surface 122 , a second surface 124 opposite to the first surface 122 , and a plurality of through holes 126 passing through the first surface 122 and the second surface 124 . The number of the through holes 126 generally corresponds to the number of the light emitting elements 14 . Electrical connections (not shown) are provided on the printed circuit board 12 to form electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com