Seamless long bamboo sectional material

A bamboo profile, seamless technology, applied in the direction of slender components, wood treatment, wood processing equipment, etc., can solve the problems of insufficient transverse connection strength, limit the processing of bamboo products, increase the difficulty of cleaning, etc., to save bamboo resources and protect Bamboo assets, little deformability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

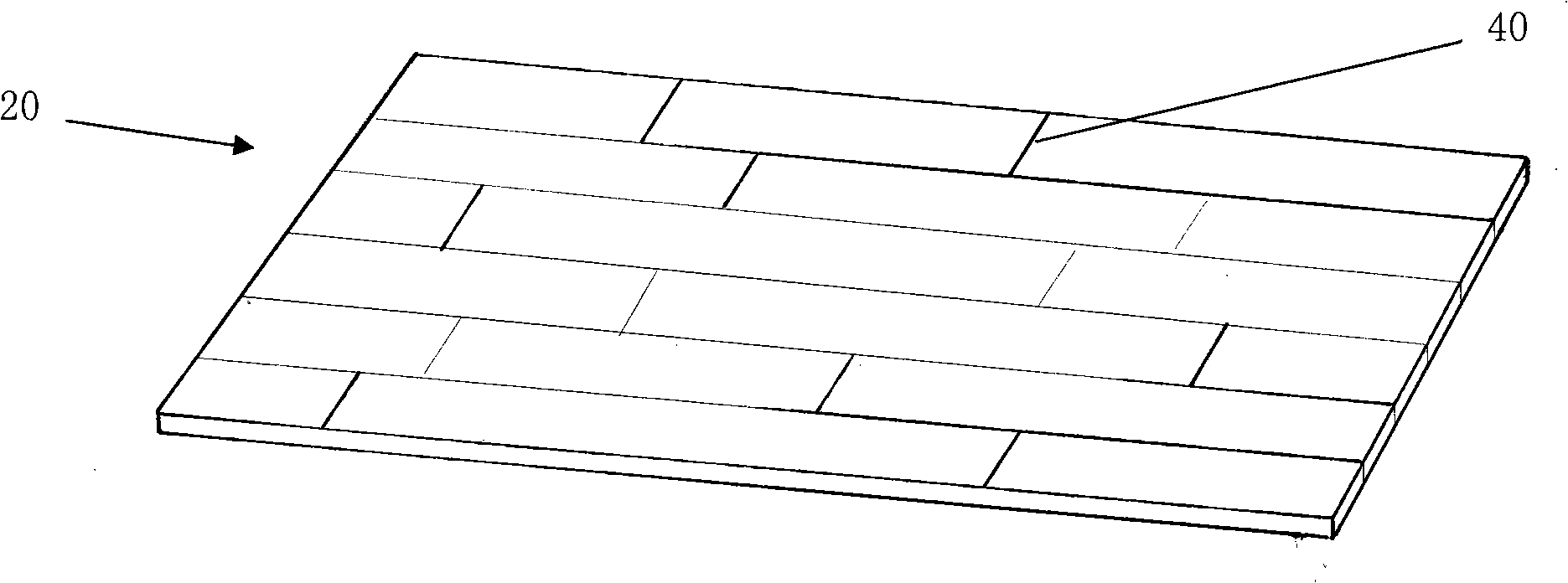

[0063] see Figure 5 As shown in the structural schematic diagram of the bamboo profile in Example 1 of the present invention, two single-layer boards A30, 31 are stacked in the same direction with each other, and composite molding is adopted, and side pressing and hot-pressing are carried out under the press. The hot-pressing temperature 85~165℃, pressure 5~35kg / cm 2 , made of bamboo profiles.

Embodiment 2

[0065] see Figure 6 As shown in the structural schematic diagram of the bamboo profile in Example 2 of the present invention, the three-layer single-layer boards A30, 31, 32 are stacked vertically and horizontally with each other, and pressed and composited. , hot pressing temperature is 85~165℃, pressure is 5~35kg / cm 2 , made of bamboo profiles.

Embodiment 3

[0067] see Figure 7 As shown in the structure schematic diagram of the bamboo profile in Example 3 of the present invention, a single-layer board B20 is sandwiched between two single-layer boards A30 and 31, and the three single-layer boards are stacked vertically and horizontally with each other, pressed and compositely formed, and the molding method For: side pressure hot pressing composite under the press, the hot pressing temperature is 85 ~ 165 ℃, the pressure is 5 ~ 35kg / cm 2 , made of bamboo profiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com