Device for drilling miniature borehole on ultra-short radius of coiled tubing

An ultra-short-radius, tiny wellbore technology, which is applied to drilling drives, drilling equipment, and directional drilling in the wellbore. It can solve problems such as downhole accidents and pin failures, save drilling costs, and increase axial area. , Improve the effect of transmission while drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

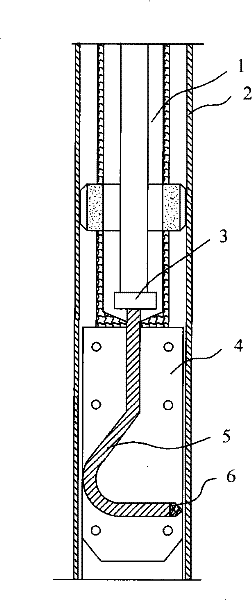

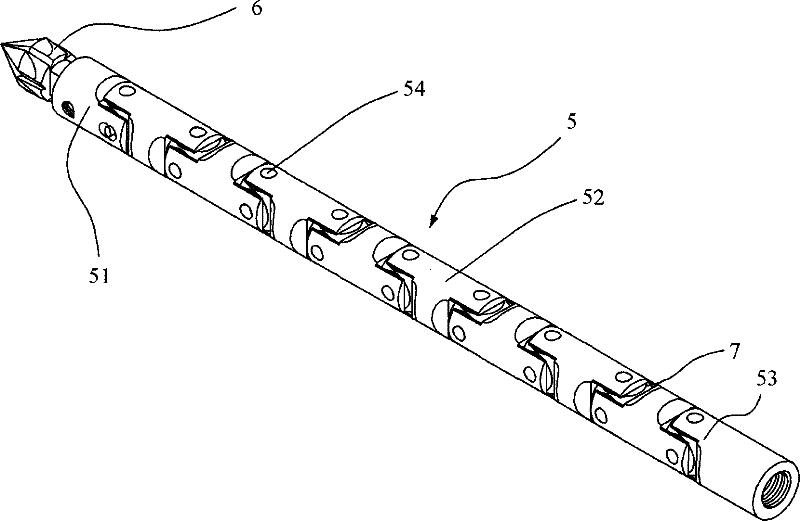

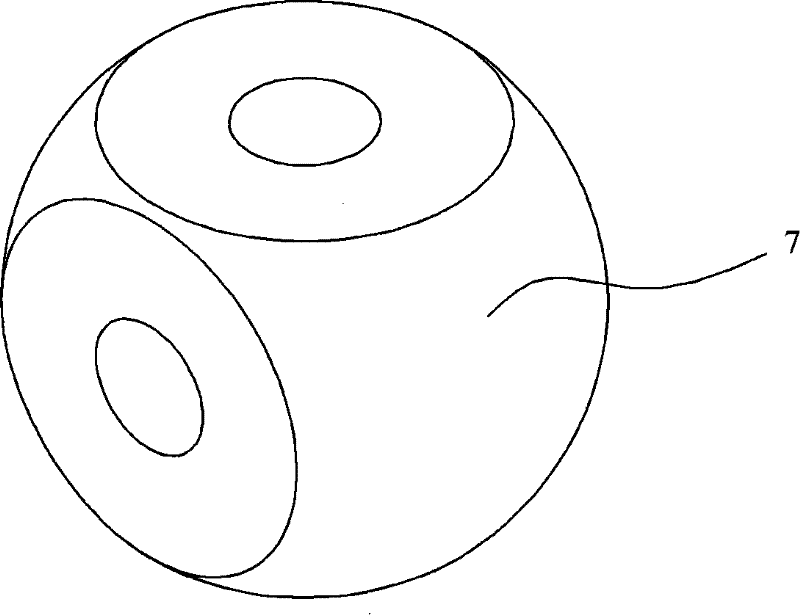

[0011] Such as figure 1 , 2 As shown, the present invention includes: a coiled tubing 1, a guide 4, a flexible transmission shaft 5, a drive motor 3 and a drill bit 6; the flexible transmission shaft 5 is installed in the guide 4, and the drill bit 6 is arranged at the output end of the flexible transmission shaft 5, The driving motor 3 is arranged at the input end of the flexible transmission shaft 5; the flexible transmission shaft 5 includes more than three transmission joints, the transmission joints are connected by ball joints 7, and the transmission joints and the ball joints 7 are in surface contact. The oil flow in the coiled tubing 1 makes the driving motor 3 rotate, thereby driving the flexible transmission shaft 5 to rotate.

[0012] The specific setting method of the flexible transmission shaft 5 is as follows: figure 2 , 3 As shown, the transmission section includes a top section 53 connected to the drive motor 3, a bottom section 51 connected to the drill bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com