Method and apparatus of impulse fluid jet type membrane bioreactor

A membrane bioreactor, pulse jet technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems such as inconvenience of operation, and achieve energy saving, operating energy consumption and operating noise. Low, increase the effect of biochemical reaction rate

Active Publication Date: 2011-01-05

GO HIGHER ENVIRONMENT GRP CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the continuous jet aeration, the membrane fouling can only be further controlled by adjusting the aeration volume, and because the gate valve is used to control the circulation pump flow, the operation is inconvenient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

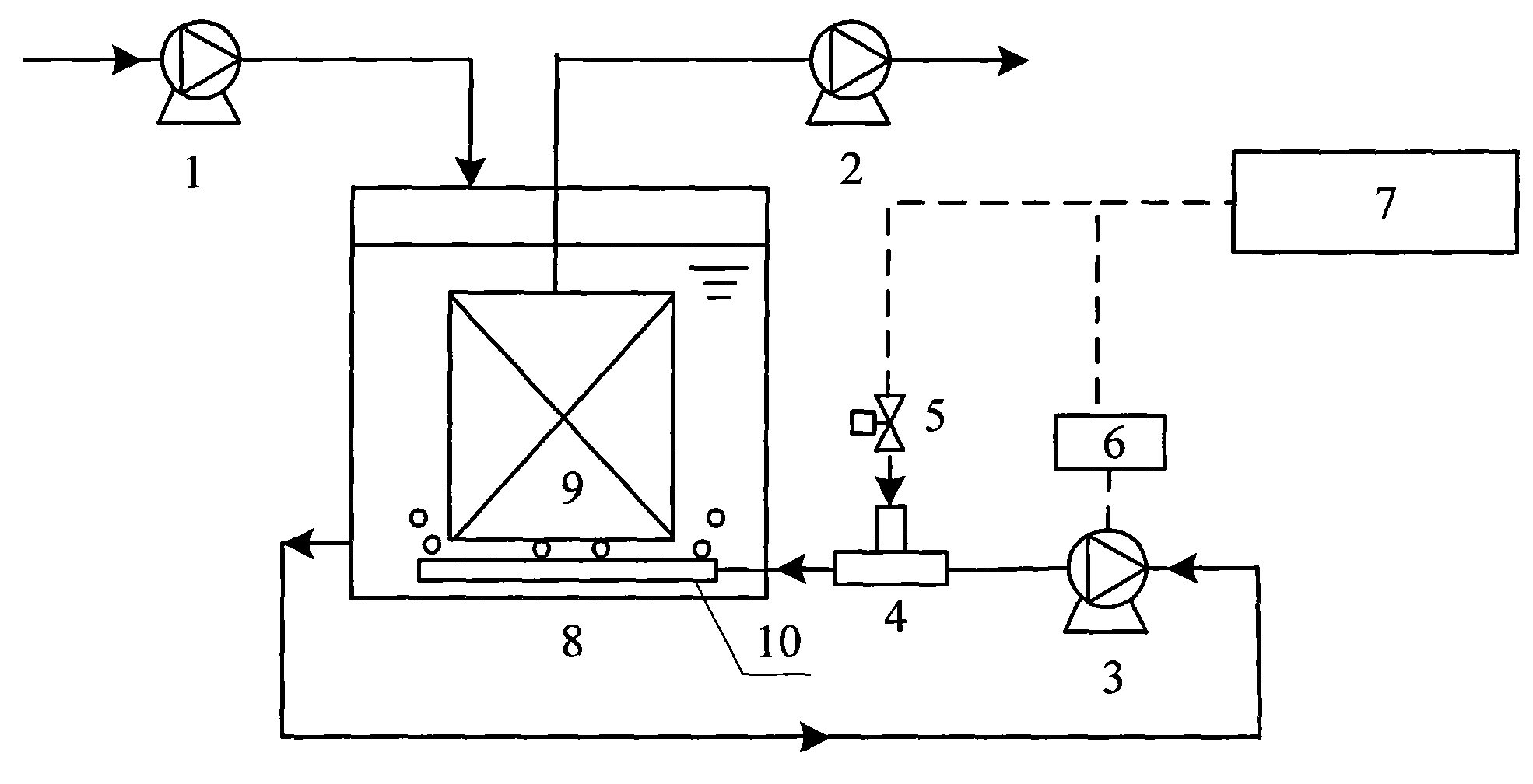

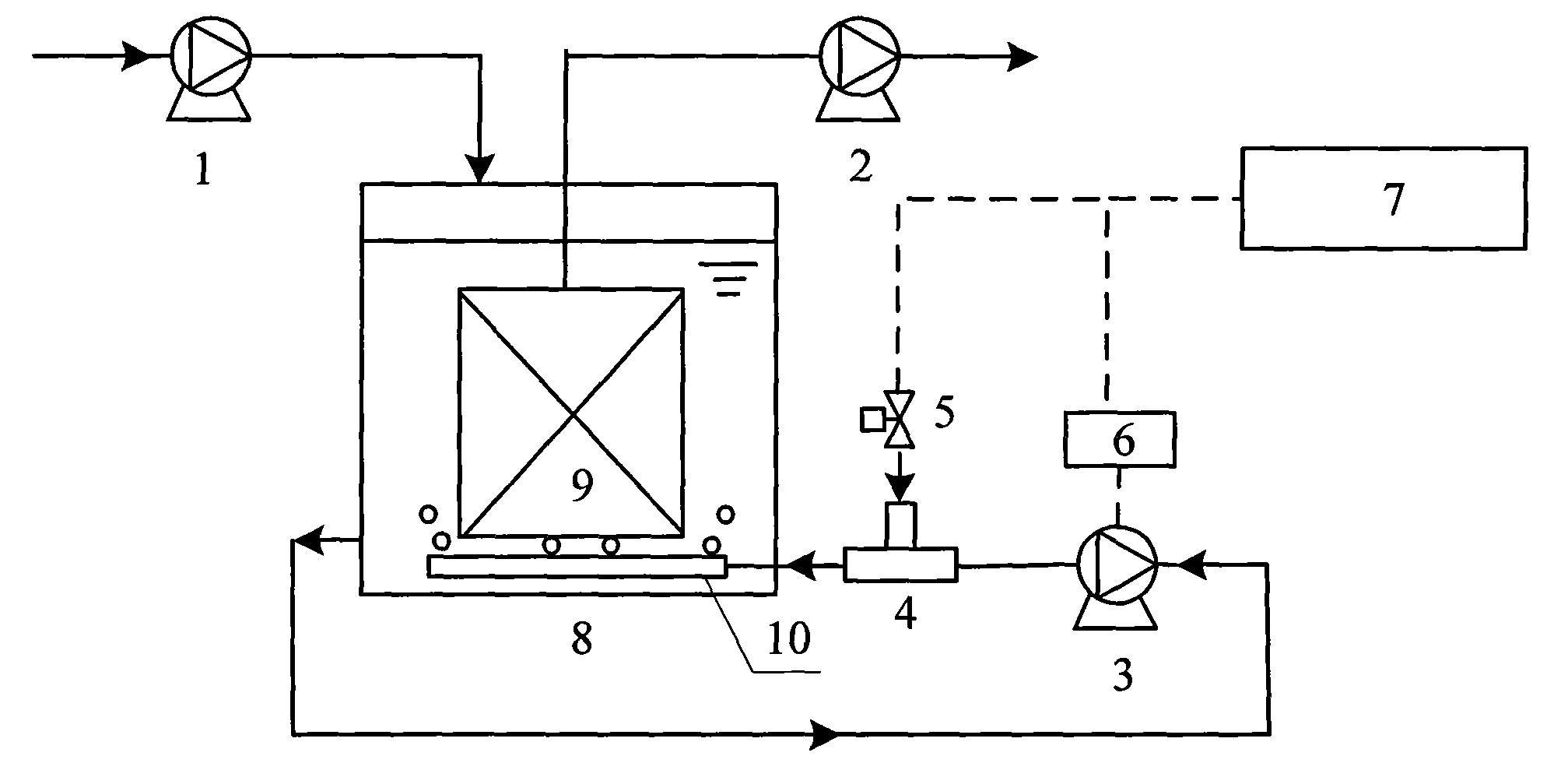

The invention provides a method of a pulse-jet membrane bioreactor and a device for realizing the method. The method adopts a jet aerator to replace a traditional blower to realize the cross-flow scouring effect of membrane components; wherein, circulating fluid flows through the jet aerator at high speed; air enters the jet aerator in a pulse way by a valve controlled by PLC and jets at the bottom through a gas spreading distributor; the PLC system regulates the cross-flow state of gas-liquid two-phase flow on the membrane surface by changing circulation flow rate and pulse frequency, so as to improve the scouring effect of the air to the membrane surface, to further control membrane pollution, to improve the energy utilization efficiency of a circulating pump and to reserve energy. The use of the jet aerator also increases the utilization efficiency of oxygen and improves sludge degradation effect. The device has the advantages of low operation energy consumption and low operation noise, slight membrane pollution, less early investment in equipment, simple structure of the device, small occupation area, simple and convenient operation and convenience in automatic running and control.

Description

Device and method of use of a pulse jet membrane bioreactor technical field The invention relates to a pulse-jet type membrane bioreactor device and use method, and belongs to the technical field of sewage treatment and reuse, and membrane bioreactors. Background technique With economic development and population growth, the scale of cities in our country continues to expand, water consumption continues to increase, and water supply is increasingly insufficient. The continuous improvement of the level of urbanization and the rapid development of industry have made the water environment pollution more and more serious. In order to solve the problems of water resource shortage and water environment pollution, many countries have carried out research on sewage recycling. Membrane bioreactor (Membrane Bioreactor, MBR) has received widespread attention due to its excellent and stable effluent quality. The research on MBR began in the 1960s. As a new and efficient sewage treat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F3/12

CPCY02W10/10

Inventor 陈福泰范正虹麻丽峰邢林林

Owner GO HIGHER ENVIRONMENT GRP CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com