Controller with pulling resistant structure

A controller and anti-pull technology, which is applied to the parts, electrical components, coupling devices, etc. of the connecting device, which can solve the problems of occupying space, less than ideal structure, and troublesome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

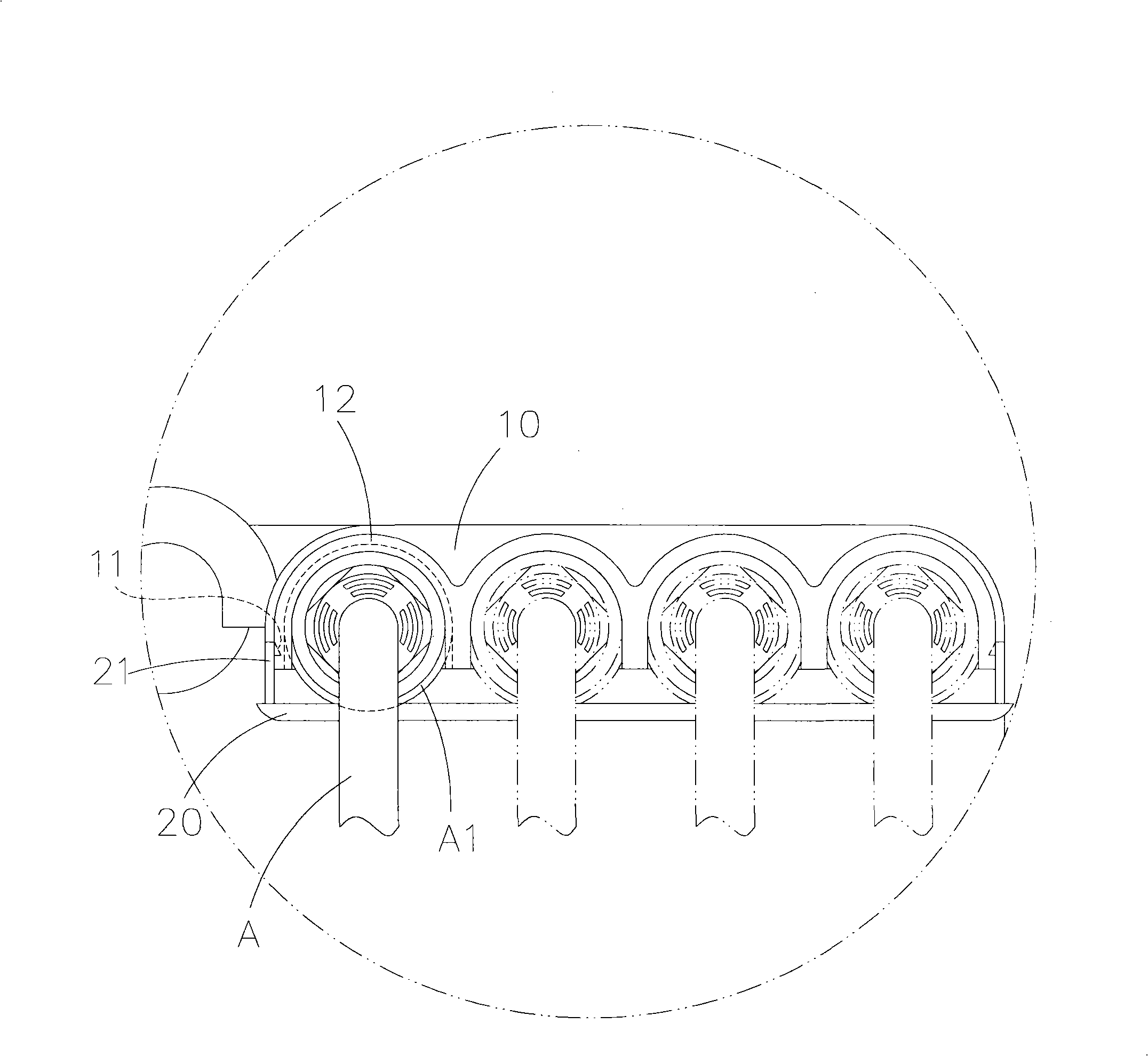

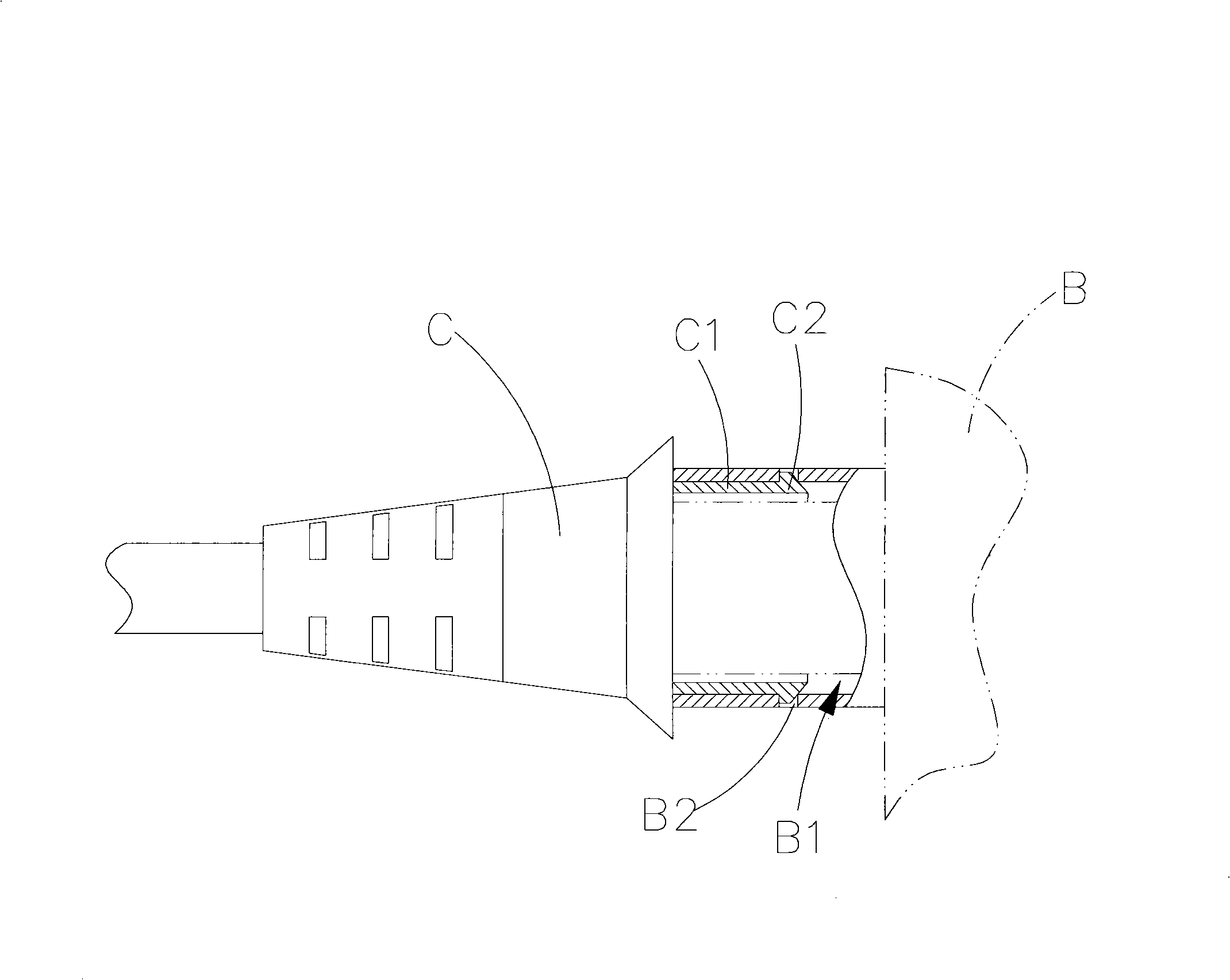

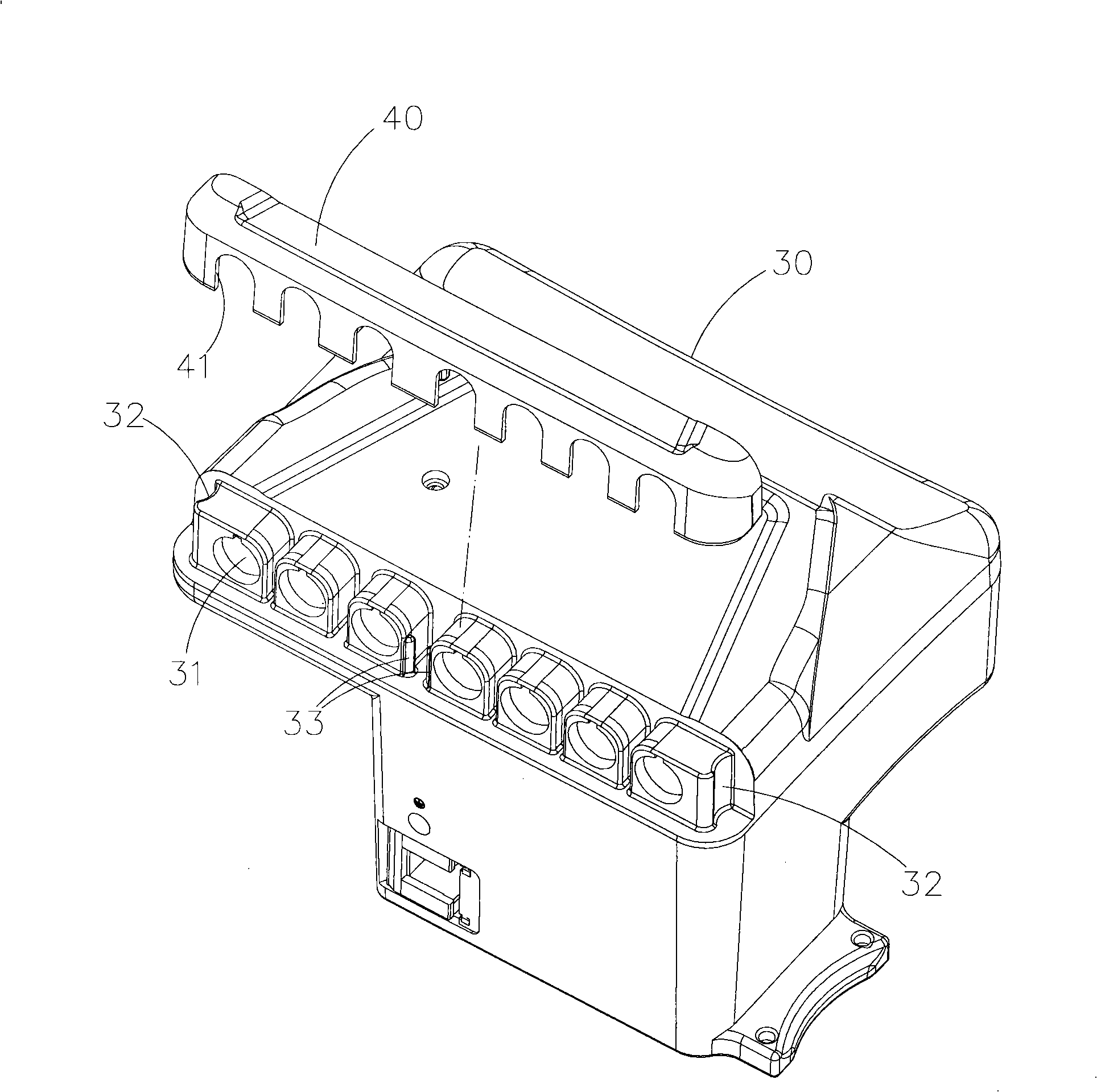

[0034] The controller of the present invention has an anti-pull structure, for example Figure 3 to Figure 7 As shown, the pull-out prevention structure is assembled in the embodiment of the controller such as image 3 and Figure 4 shown, where:

[0035] The controller 30 has a plurality of jacks 31 and joints S detachably inserted into the jacks 31. In this embodiment, the controller 30 forms a positioning recess 32 at its two ends, and each positioning The concave direction of the concave 32 is perpendicular to the insertion direction of the jack, and two convex parts 33 with opposite protrusion directions are formed on the controller 30, and the protrusion direction of each protrusion is perpendicular to the insertion direction of the jack. ;as well as

[0036] The anti-extraction structure 40 is assembled on the controller 30 corresponding to the jack 31 of the controller 30, and the anti-extraction structure 40 forms cutouts 41 corresponding to the number and shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com