Short tranverse crankshaft connecting rod device of warp knitting machine

A technology of crankshaft connecting rod and warp knitting machine, which is applied in the field of warp knitting machine, and can solve problems such as large vibration, difficult speed, and large movement of knitting elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

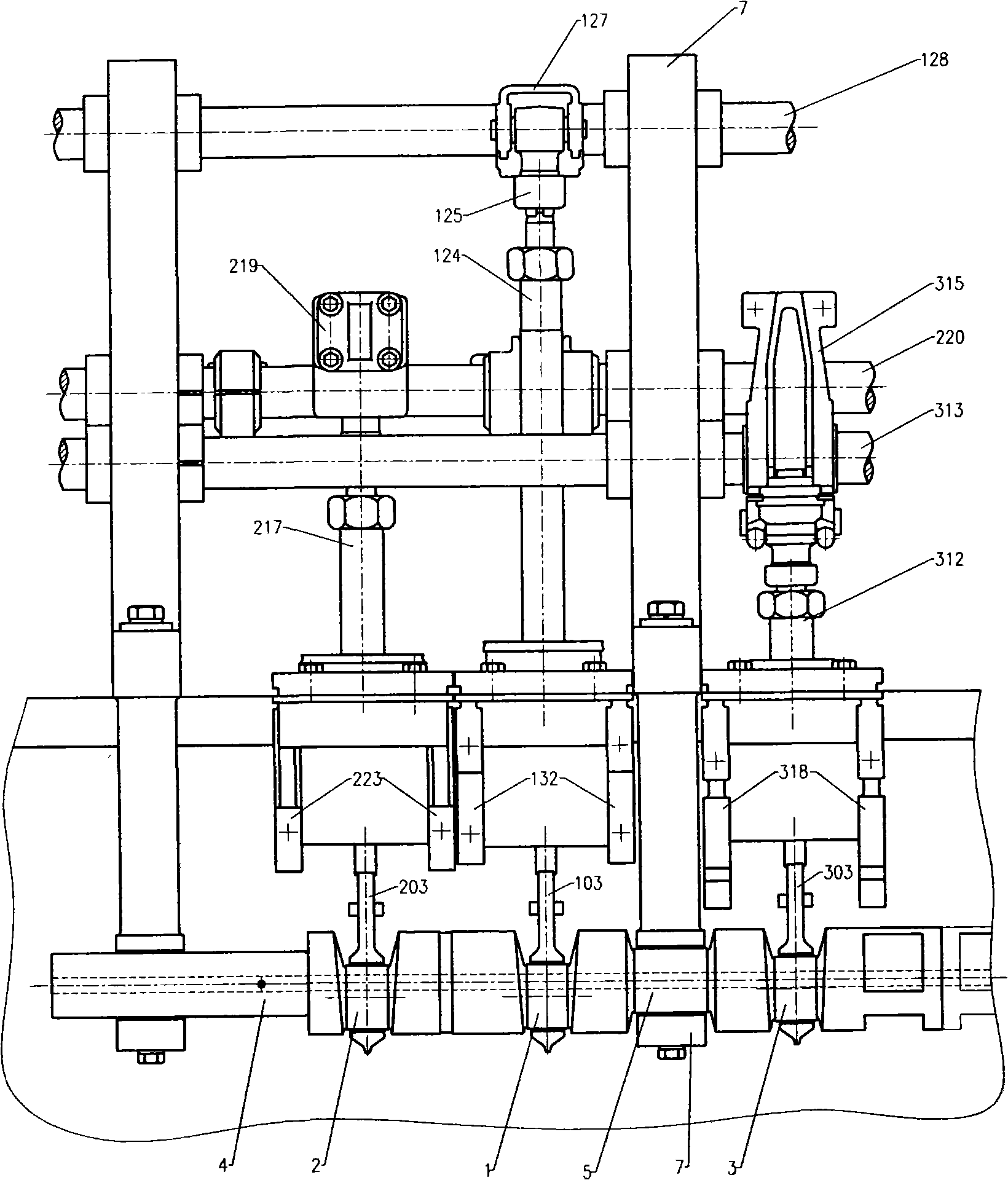

[0016] see figure 1 , a kind of warp knitting machine short stroke crankshaft connecting rod device of the present invention, comprises eccentric shaft, axle journal, middle wall plate, and its innovative point is: also be provided with the groove needle bed that is connected with eccentric shaft 1, guide needle Bed crankshaft linkage mechanism, needle core bed crankshaft linkage mechanism connected with eccentric shaft 2, sinker bed crankshaft linkage mechanism connected with eccentric shaft 3, said journal 4 is fixedly connected to the end of eccentric shaft 2 , the journal 5 is fixedly connected to the end of the eccentric shaft 3 , and the eccentric shafts 2 , 1 , 3 are connected in sequence and rotate around the journals 4 , 5 .

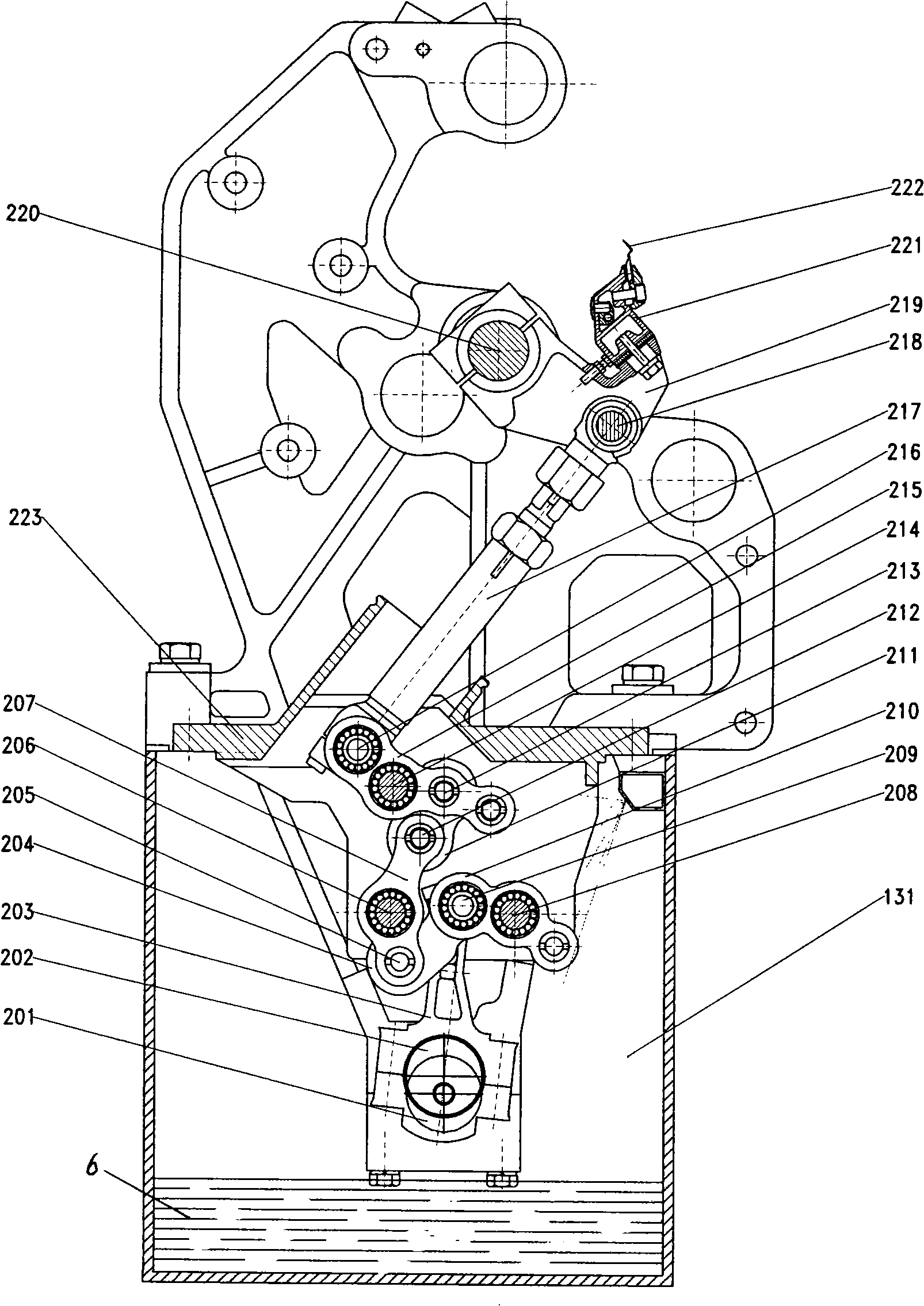

[0017] Depend on figure 2 It can be seen that the crankshaft linkage mechanism of the grooved needle bed and the yarn guide needle bed includes the groove needle bed, the yarn guide needle bed crankshaft 101, and the eccentric journal of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com