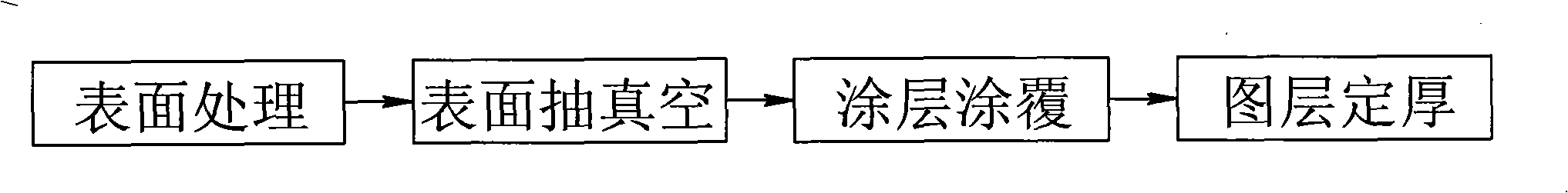

Vacuum coating technique of external surface coating and coating device

A technology of vacuum coating and process method, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., which can solve the problems of not being able to coat thickly at one time, increased processing costs, and local corrosion of metals, and achieve reduction Waste of manpower and materials, increased contact area, and high-quality production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In order to solve the problem of insufficient adhesion and subsidence of the scraping putty before spraying the primer on the fiberboard in the wood-based panel, which leads to the need for multiple scraping, this device is used to implement as follows:

[0025] (1) The workpiece processed by the MDF is smoothed with sandpaper or abrasive belt, the burrs are removed, and the surface is cleaned with a vacuum cleaner, and the pretreatment is completed.

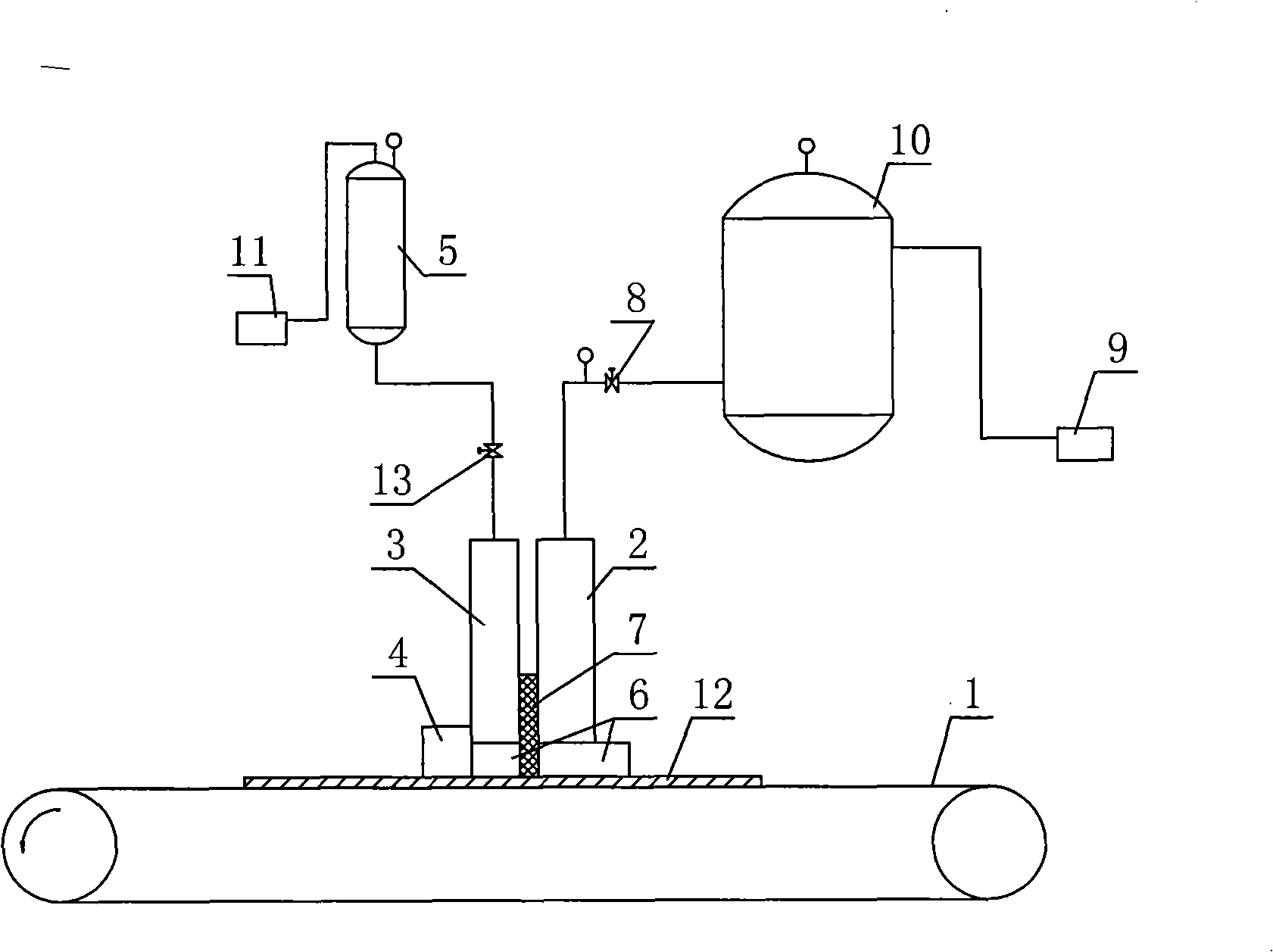

[0026] (2) Start the vacuum pump 9, the vacuum aspirator 2 is connected with the vacuum pressure tank 10 (pressure-0.09MPa), the MDF is a porous non-completely airtight material, and the vacuum aspirator 2 is divided into two suction ports, which can be adjusted independently Vacuum pressure, the size of the front suction port is large (pressure -0.06~-0.07MPa), which is convenient for rapid suction and degassing, and the rear suction port is narrow (pressure -0.07~-0.08MPa), so as to ensure the elasticity of the tail of t...

Embodiment 2

[0034] A curved plastic panel was originally sprayed with a special PU primer, and then re-sprayed with a PU high-gloss topcoat. The utilization rate is 50%. The paint mist and solvent volatilization lead to poor working environment, and long-term operation is easy to cause occupational diseases. Now use this process and special equipment to process as follows:

[0035] (1) The surface of the curved plastic plate needs to be painted with 200-mesh silica sand, then washed with deionized water and dried.

[0036] (2) Start the vacuum pump 9, the vacuum aspirator 2 is connected with the vacuum pressure tank 10 (pressure-0.03MPa), the plastic part is a completely airtight material, the vacuum aspirator is divided into 1 suction port, and the vacuum pressure is adjusted- 0.02~-0.01MPa; the elastic seal 6 is made of 3mm thick silicone film, and the elastic seal 6 is also processed into an arc according to the arc of the board, and can be naturally and tightly pressed on the board u...

Embodiment 3

[0044] The surface of a steel metal ceiling needs to be coated with colored solid-color acrylic paint. The focus is on the adhesion and anti-corrosion protection of the paint film, and the fullness of the paint film is not high. Agent = 1: 0.5: 0.7, now adopt this process and device as follows:

[0045] (1) After sandblasting, alkali washing, pickling, and phosphating, the plates are washed with deionized water and dried.

[0046] (2) Start the vacuum pump 9, the vacuum aspirator 2 is connected with the vacuum pressure tank 10 (pressure-0.06MPa), the vacuum aspirator 2 is a suction port, adjust the vacuum pressure -0.04~-0.05MPa; the elastic seal 6 It is made of 3mm thick silicone film, which can be naturally and tightly pressed on the plate under the action of vacuum negative pressure; the elastic sealing spacer 7 is made of 10mm thick silicone film.

[0047] (3) The paint formula is adopted as paint: curing agent: diluent=1: 0.5: 0.2, the paint is filled in the feed storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com