Semi-opening type coal bed gas nitrogen dilated and liquefied process taking advantage of variable pressure for adsorbing residual pressure

A pressure swing adsorption and coalbed methane technology, which is applied in liquefaction, refrigeration and liquefaction, chemical instruments and methods, etc., can solve the problems of insignificant energy saving effect of coalbed methane compression power consumption, and achieve significant energy saving effect and the effect of reducing liquefaction work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

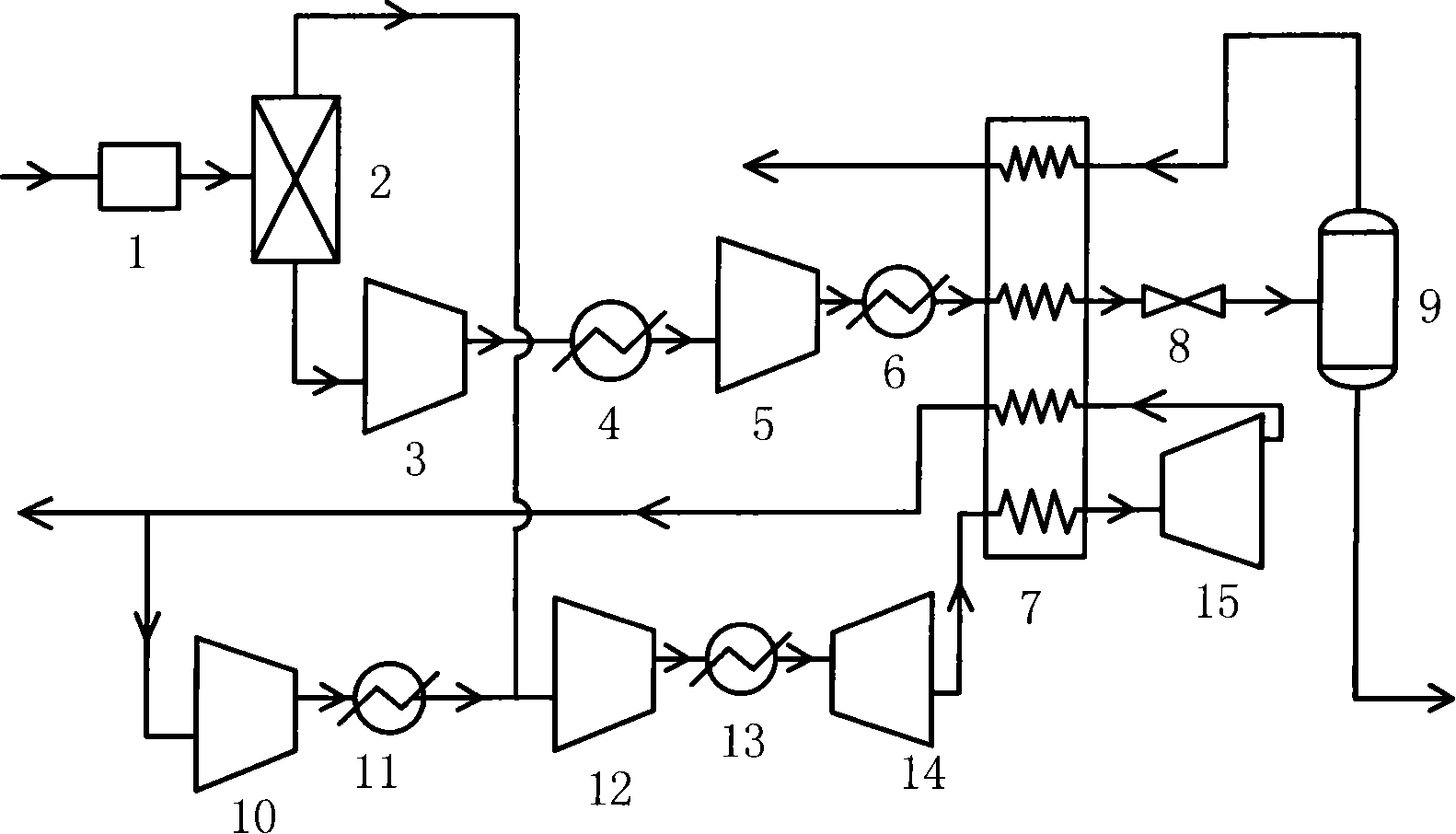

[0018] Implementation Option 1: If figure 1 As shown, the semi-open coalbed gas nitrogen expansion liquefaction process when the adsorption residual pressure is lower than 3MPa includes the following steps:

[0019] 1. Deoxygenation, desulfurization, decarburization, and drying of pressured normal-temperature CBM raw material gas in the pre-purification system 1 in the conventional natural gas liquefaction process;

[0020] 2. The pre-purified coalbed methane is enriched by pressure swing adsorption in the adsorber 2, and the concentrated coalbed methane with residual pressure nitrogen and normal pressure is separated. The adsorber (2) uses molecular sieve or activated carbon adsorber;

[0021] 3. The concentrated coalbed methane is compressed to a medium pressure of 0.6-0.8 MPa by the primary compressor 3 and compressed by the secondary compressor 5 to be greater than or equal to 4.5 MPa, and is water-cooled in the first cooler 4 and the second cooler 6 respectively. room te...

Embodiment approach 2

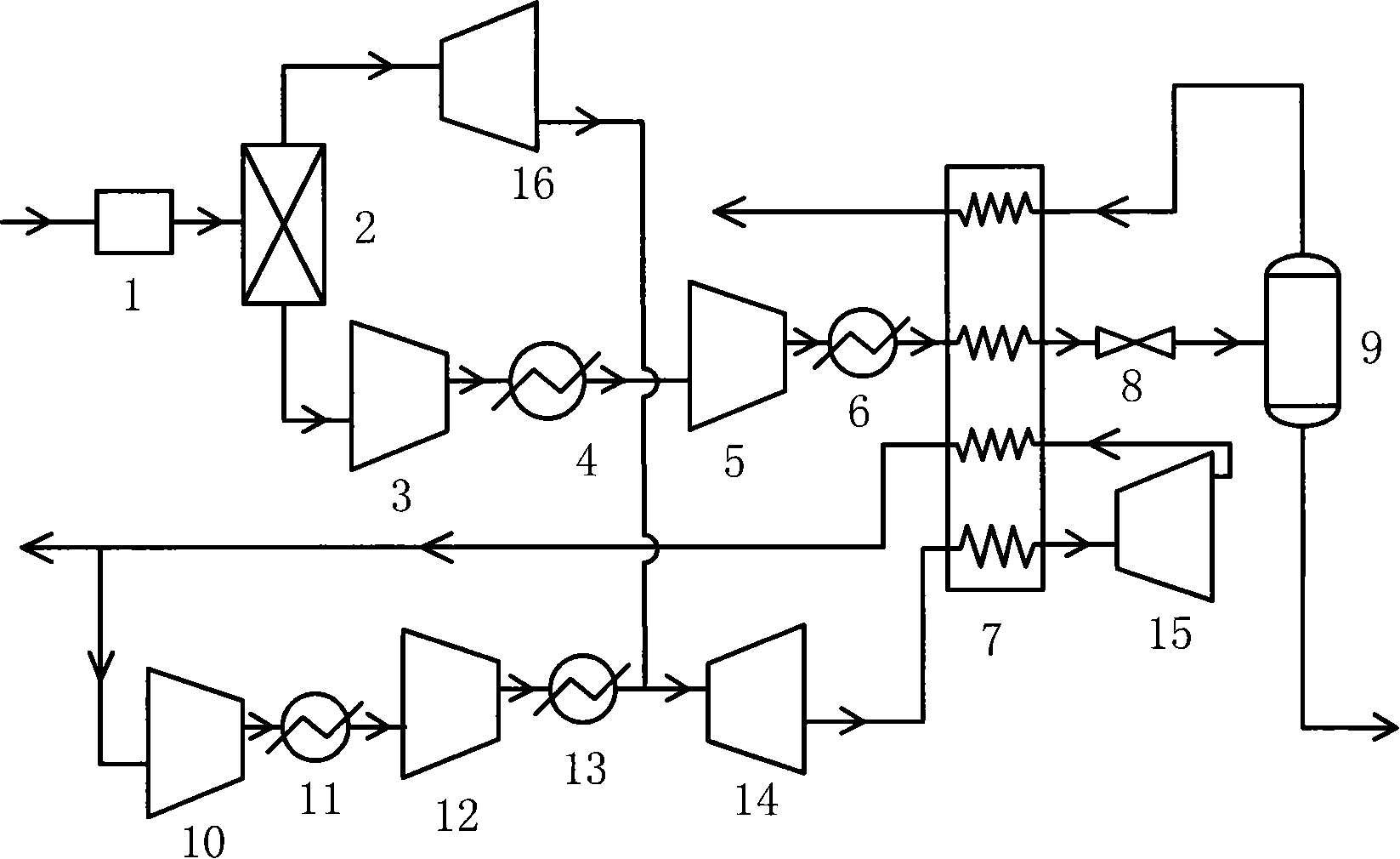

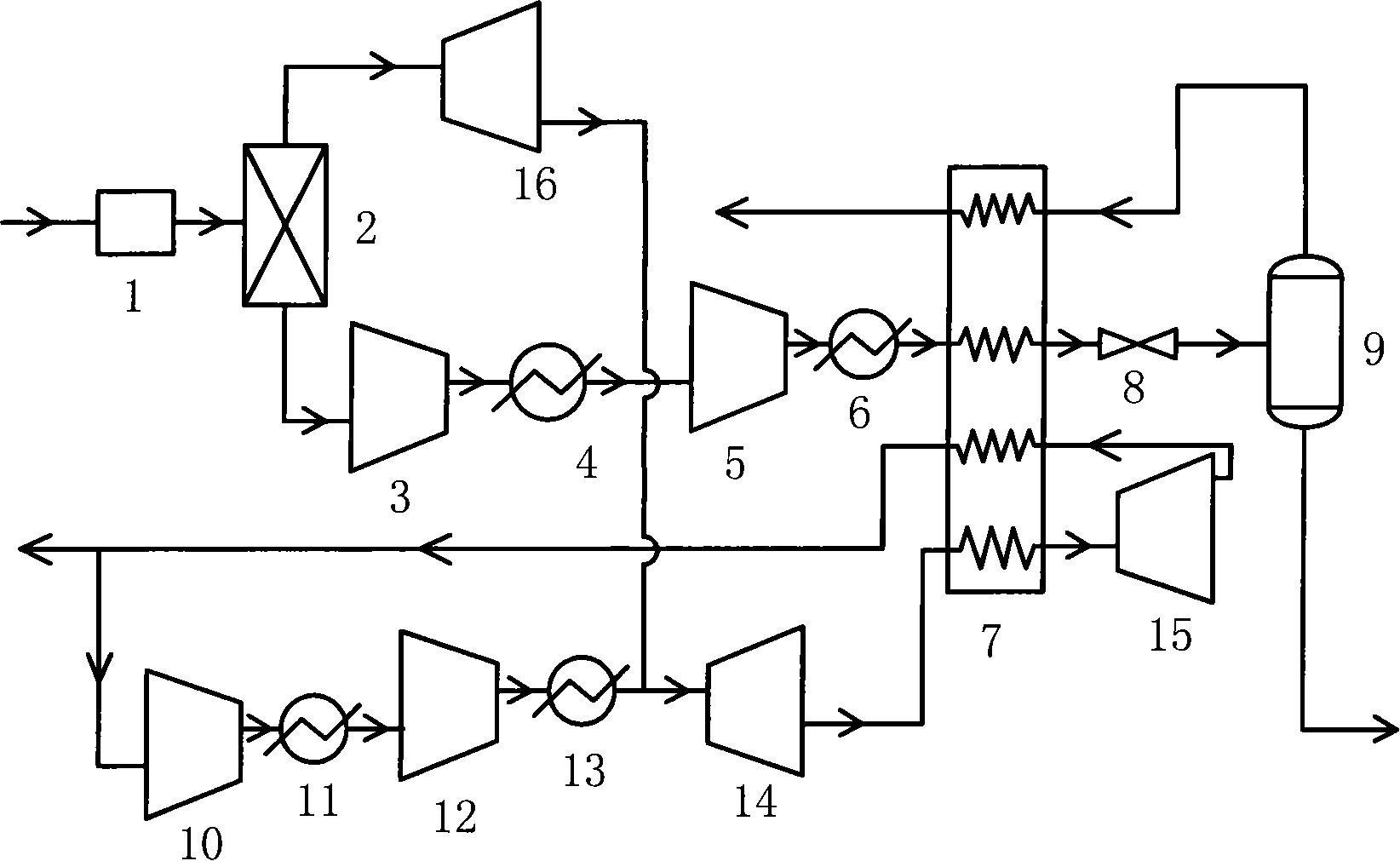

[0024] Implementation Option 2: If figure 2 As shown, the semi-open CBM nitrogen expansion liquefaction process when the adsorption residual pressure is higher than 3MPa includes the following steps:

[0025] Step 1, step 2 and step 3 are respectively the same as step 1 in embodiment 1, step 2 and step 3;

[0026] 4. The high-pressure concentrated coal-bed methane is cooled into low-temperature concentrated coal-bed methane in the heat exchanger 7. Part of the required cooling capacity is provided by the semi-open nitrogen expansion cycle, and the other part is provided by the cold gas separated from the gas-liquid separator. supply. The semi-open nitrogen expansion cycle is as follows: the nitrogen with excess pressure separated by adsorption is first expanded to 3MPa in the excess pressure nitrogen expander 16, and then compressed to 3MPa with the first-level nitrogen compressor 10 and the second-level nitrogen compressor 12 respectively. and the third cooler 11 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com