High vacuum multiple layer heat insulation quilt manufacture method

A technology of multi-layer heat insulation and production method, which is applied in heat exchange equipment, pipe protection through heat insulation, heat preservation, etc., can solve the problems of deterioration of heat insulation performance, uncertainty of the degree of influence of heat insulation performance, and damage to the reflective layer, etc., so as to shorten the wrapping time , avoid adverse effects, reduce the effect of radiation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] The manufacturing method of the high-vacuum multi-layer thermal insulation quilt of the present invention comprises the following steps:

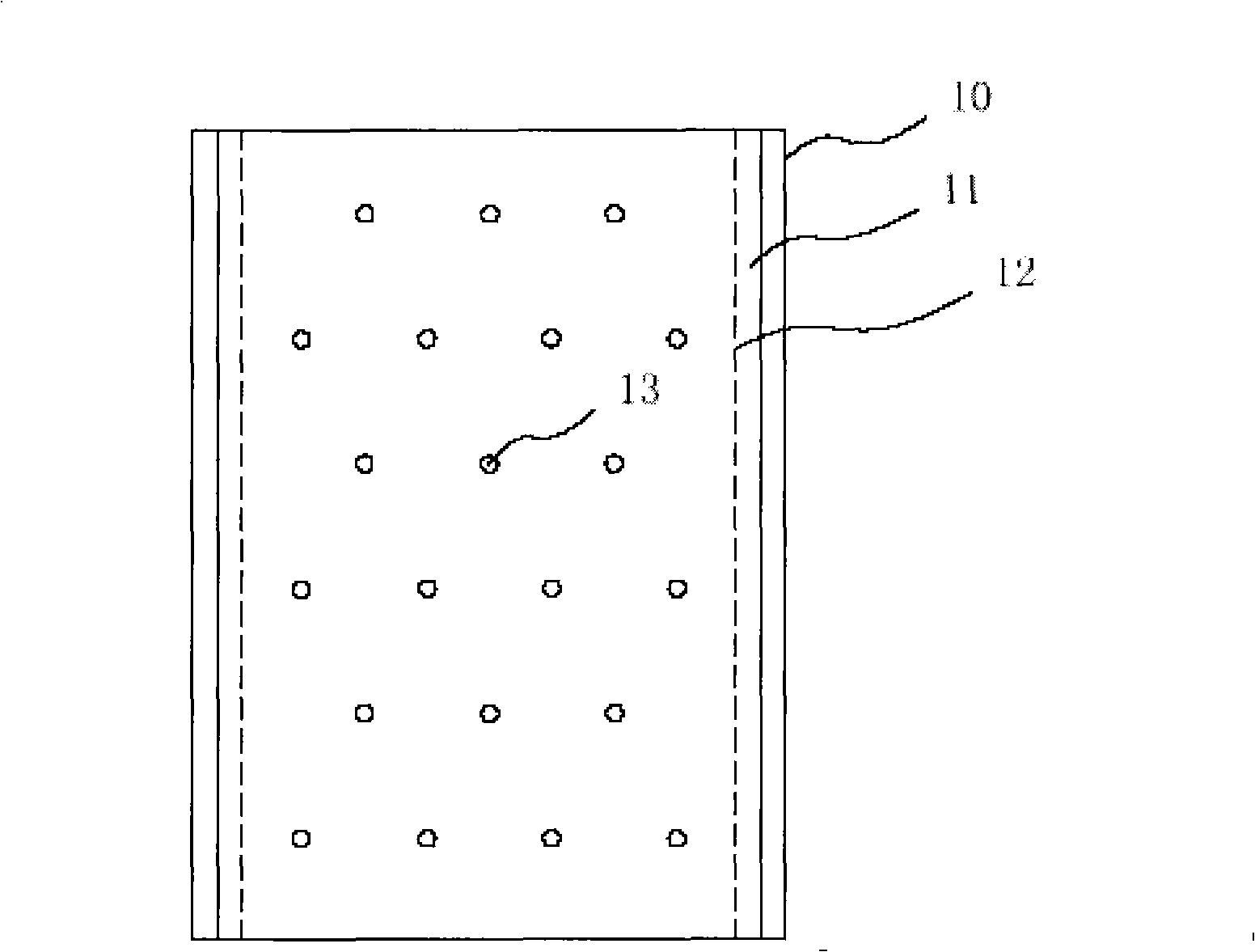

[0027] 1. Prepare a mechanized assembly line for the production of multi-layer insulation quilts. The assembly line includes: roller frame 1, feeding transmission device 4, two seaming machines 5, punching machine 6, output transmission device 7, working platform 8, two seaming machines The machine 5 is respectively located on both sides of the working platform 8, the feeding transmission device 4 is matched with the action of the two seaming machines 5, the discharge transmission device 7 cooperates with the punching machine 6 to discharge materials intermittently, and the punching machine 6 can be used in the heat-insulating quilt 9 Air holes 13 are opened on the entire width, and the heat ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com