Floating guiding hydraulic cylinder

A technology of floating guide and hydraulic cylinder, which is applied in the direction of fluid pressure actuation device, etc., can solve the problems of sealing ring wear, heat generation, damage, etc., and achieve the effect of improving working life, reducing wear and saving cost

Inactive Publication Date: 2008-10-15

CONTINUOUS CASTING TECH ENG OF CHINA

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As the working pressure of the oil cylinder increases, the tightening force of the seal ring on the piston rod also increases. Under the condition of high-speed reciprocating motion, the guide of the seal ring will wear, generate heat, and even be damaged.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

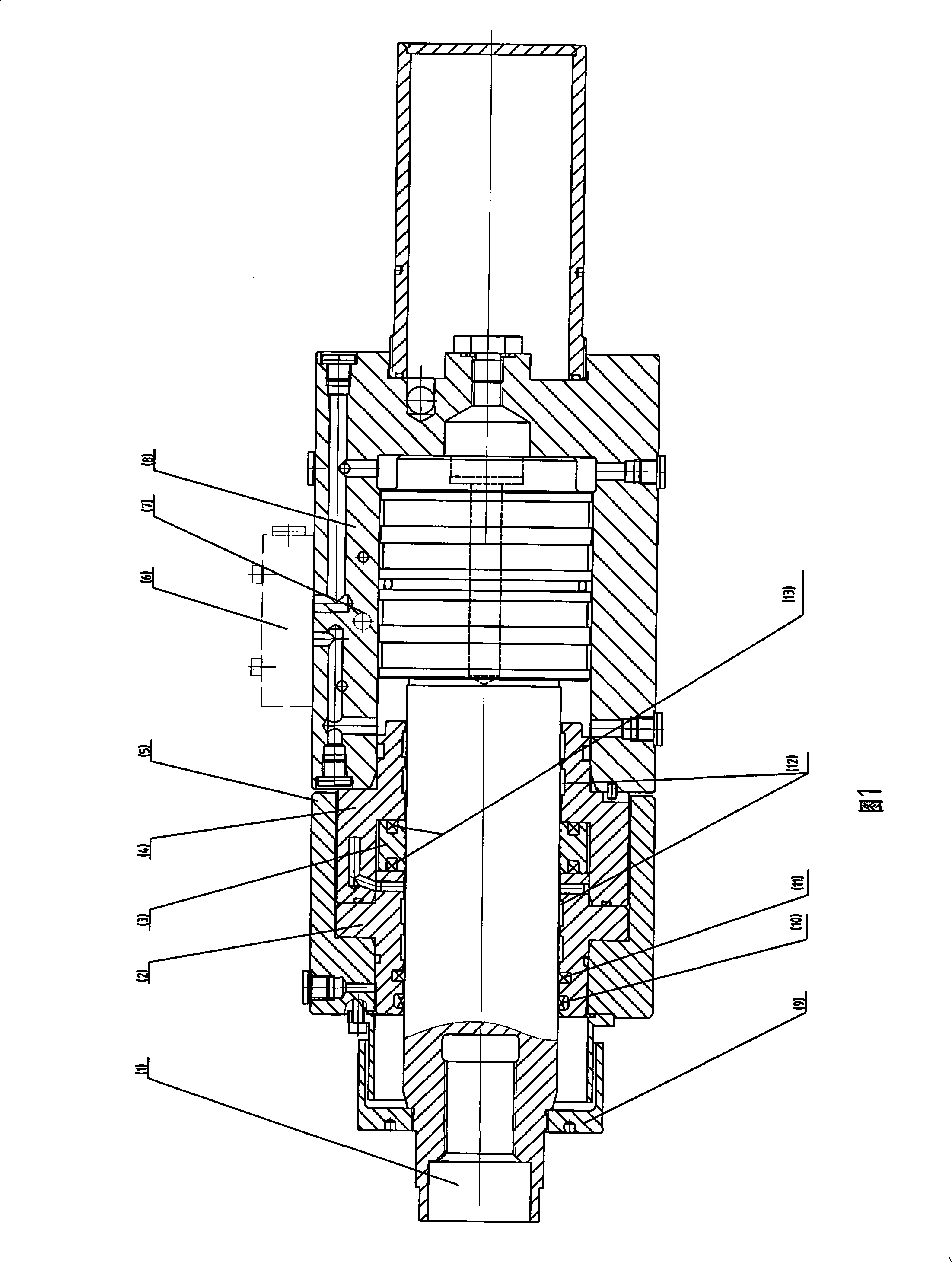

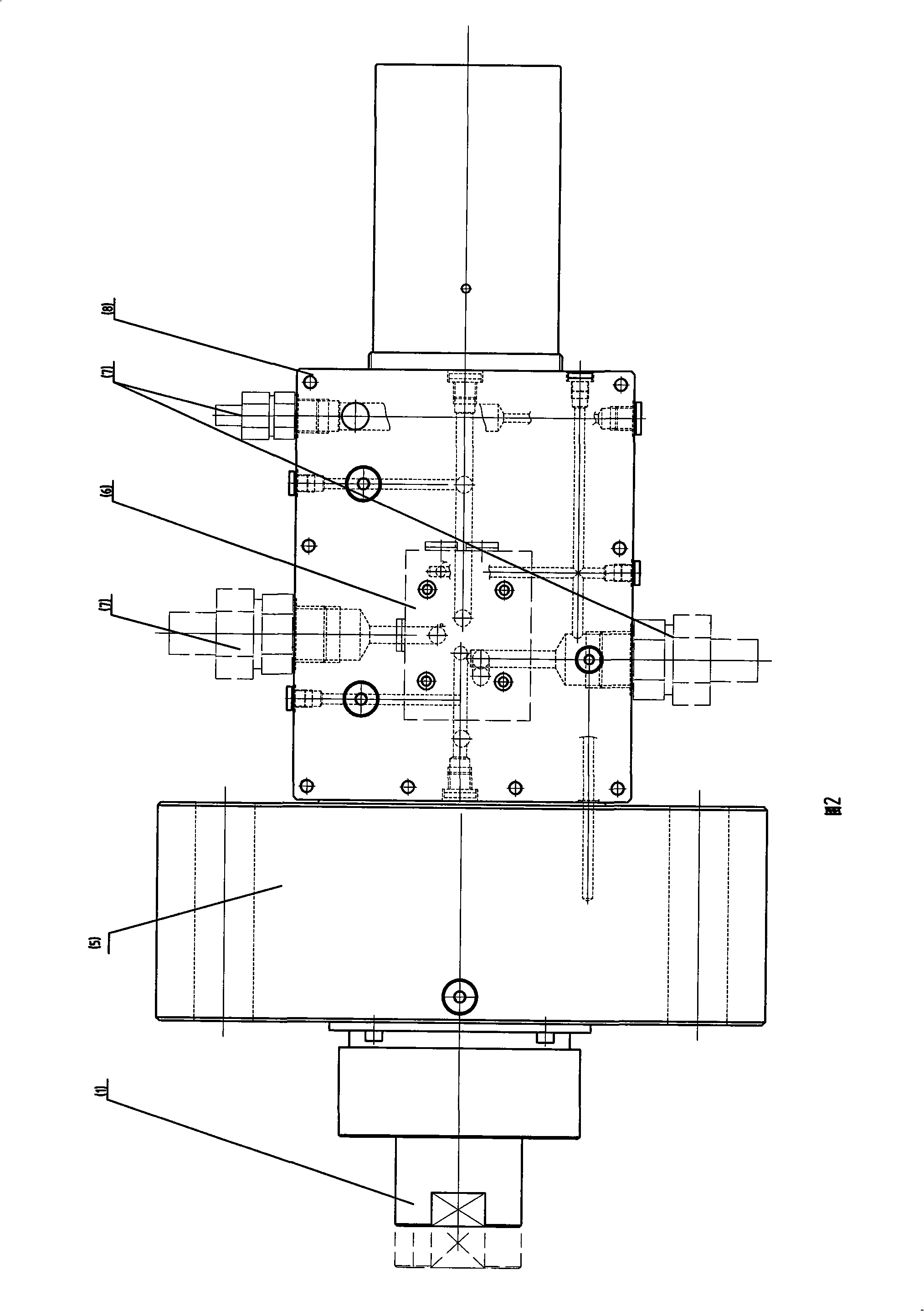

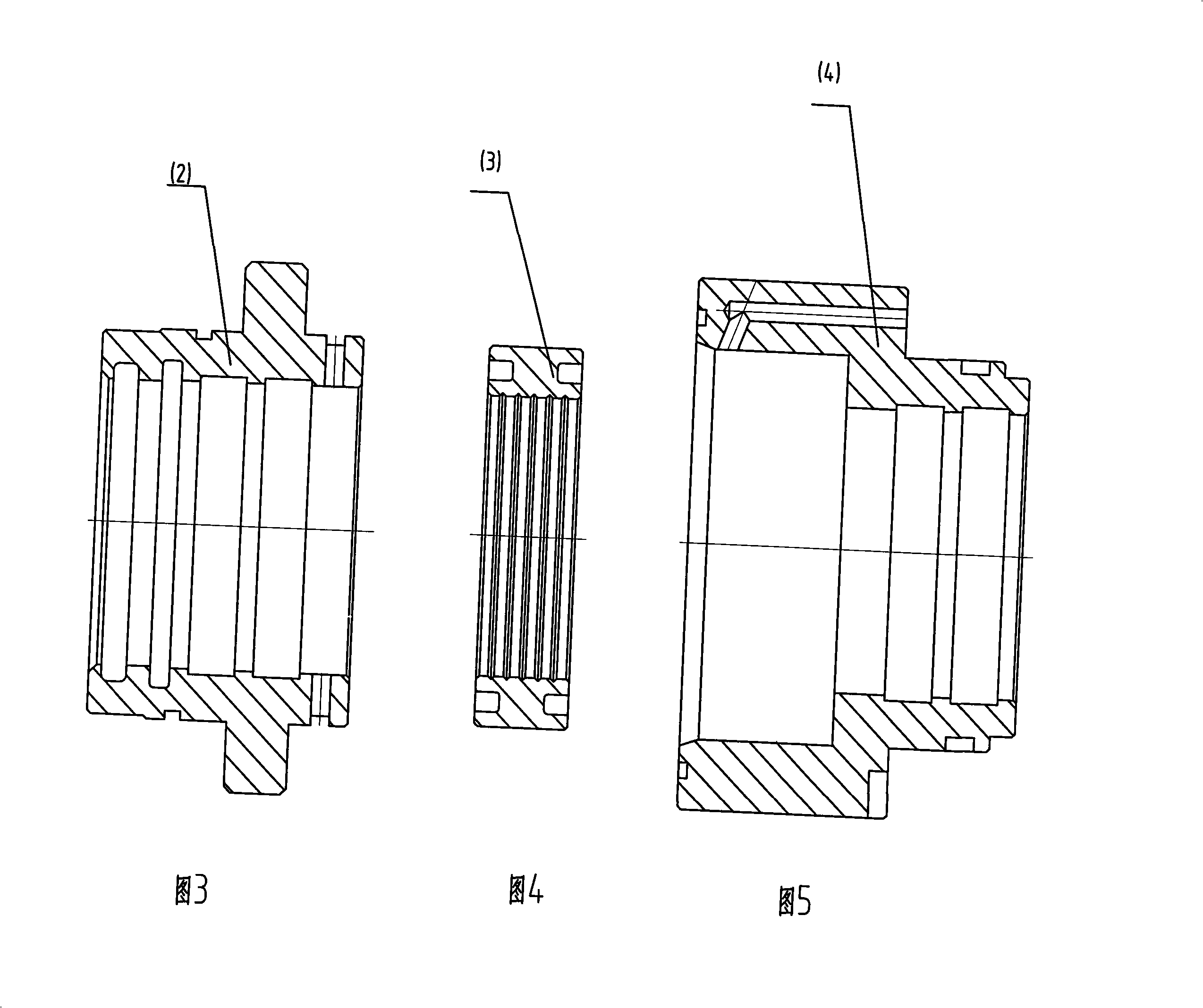

The invention discloses a floating guide hydraulic cylinder comprising a piston rod, a front gland, a hydraulic control valve, an external oil path, a cylinder barrel, sealing rings and a guide ring, and the hydraulic cylinder is characterized in that a cylinder sleeve of the hydraulic cylinder consists of a left cylinder sleeve, a floating sleeve and a right cylinder sleeve, wherein the left cylinder sleeve is sleeved on an outer surface of a piston rod, the floating sleeve is arranged between the left cylinder sleeve and the right cylinder sleeve, the floating sleeve is connected with the left cylinder sleeve and the right cylinder sleeve by the sealing rings of the floating sleeve at two ends. Clearance between the floating sleeve and the piston rod is sealed to form pressure fall, the sealing member between the left cylinder sleeve and the piston rod is in a low pressure state, which can realize better sealing and can work efficiently in a long time. The clearance of the floating sleeve is adjusted properly so that the pressure fall can be controlled well; because of presence of the floating sleeve, demand of processing precision of a matching member is reduced, thereby having low cost and convenient popularization.

Description

Floating guide hydraulic cylinder technical field This technology is widely used in places where hydraulic cylinders for hydraulic drives, servo cylinders and similar actuators are used. Due to its general processing accuracy requirements and long service life, it is especially suitable for application in the metallurgical industry where the environment is harsh and replacement is inconvenient. Background technique Most of the guides commonly used in hydraulic cylinders and servo cylinders at home and abroad are sealing rings, but the sealing materials and processing and treatment methods are continuously improved to improve the service life, which can basically meet the use requirements. As the working pressure of the oil cylinder increases, the tightening force of the seal ring on the piston rod also increases. Under the condition of high-speed reciprocating motion, the guide of the seal ring will wear, generate heat, and even be damaged. Contents of the invention Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F15B15/20F15B15/00

Inventor 周国强阎瑞河钟光

Owner CONTINUOUS CASTING TECH ENG OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com