Firtree -type bucket root steam turbine rotor blades and its locking notch vane

A moving blade and fir tree type technology, applied in the direction of machines/engines, blade support components, mechanical equipment, etc., can solve the problems of inconvenient processing, difficulty in ensuring the alignment of the two halves of the screw holes, and low work efficiency, and achieve structural Increased strength, easy assembly, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

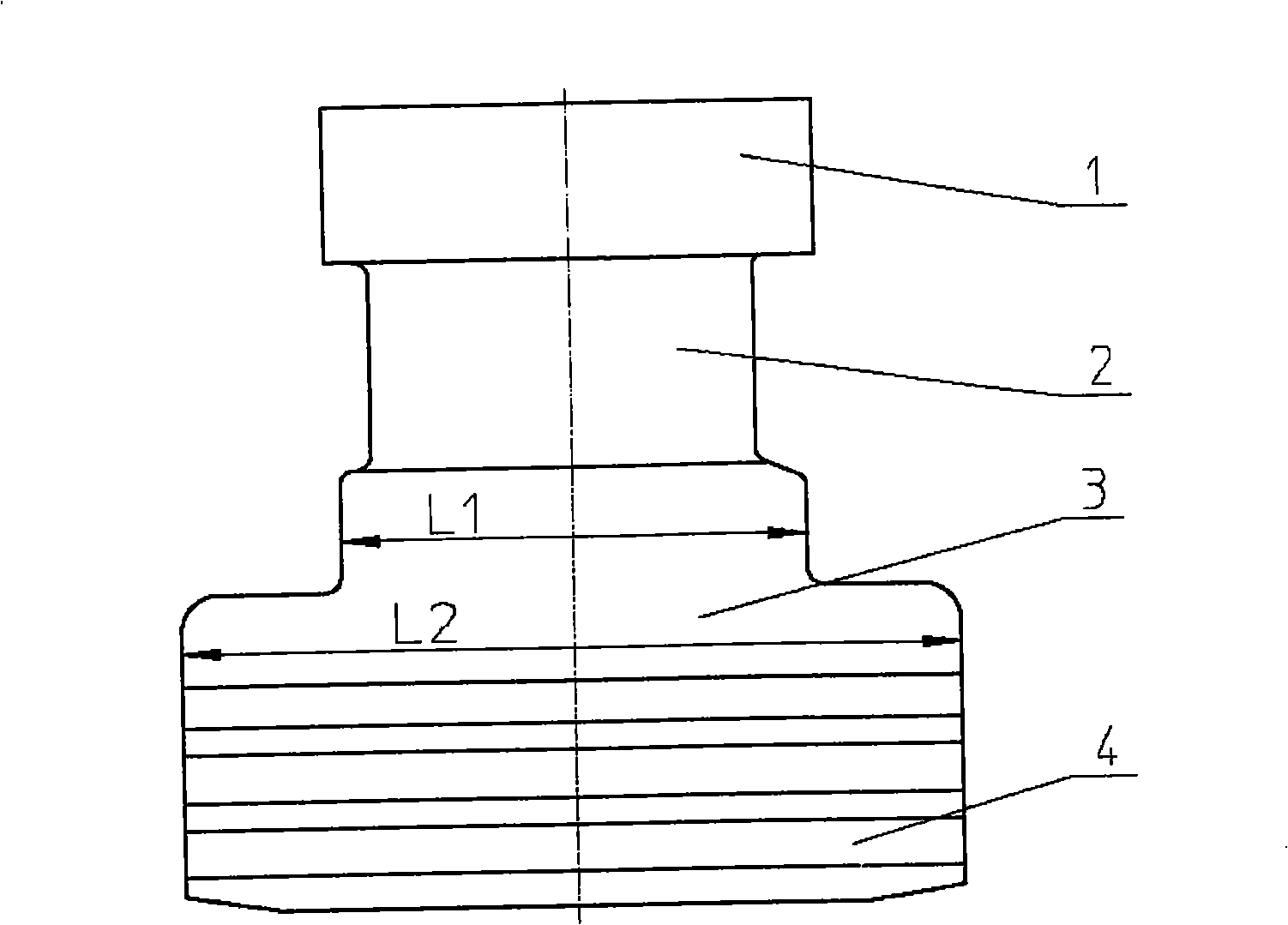

[0023] see image 3 : The fir tree type blade root moving blade has a crown 1, a blade body 2, a blade root intermediate 3, and a blade root 4, which are integral structures, wherein the axial width of the blade root intermediate 3 is L. The axial width of the blade root intermediate body 3 of the conventional blade is L 1 , the present invention is characterized in that the blade root intermediate body 3 is designed into a boss shape, and the width of the upper boss is L 1 , which is equal to the width of the root midbody of a traditional blade, and the width of the lower pedestal is L 2 , L 2 > L 1 , the width of blade root 4 is also L 2 , the dimensions of the blade root intermediate 3 and the blade root 4 are enlarged, and correspondingly, the width of the impeller is also increased to L 2 . The purpose of this improvement is twofold. First, the strength of the blade root 4 itself and the structural strength after assembly are improved, and the combination with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com