Applications of montmorillonite for bacteriostasis and corrosion protection in paper making process

A technology of papermaking technology and montmorillonite, which is applied in the field of antibacterial and antiseptic application of montmorillonite in papermaking technology, and the application field of minerals in papermaking technology, which can solve problems such as cumbersome methods, waste, and failure of sterilization

Active Publication Date: 2008-10-15

ZHEJIANG RENHENG CHEM

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the bactericidal spectrum is not wide enough, the growth and reproduction of some microorganisms cannot be controlled

There are many times of use, and the method is cumbersome. It is necessary to adjust the input site, usage amount and use frequency of the fungicide according to the specific conditions of the sludge generation. Often, the sterilization fails due to insufficient dosage, or the excessive dosage leads to waste and pollutes water resources.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

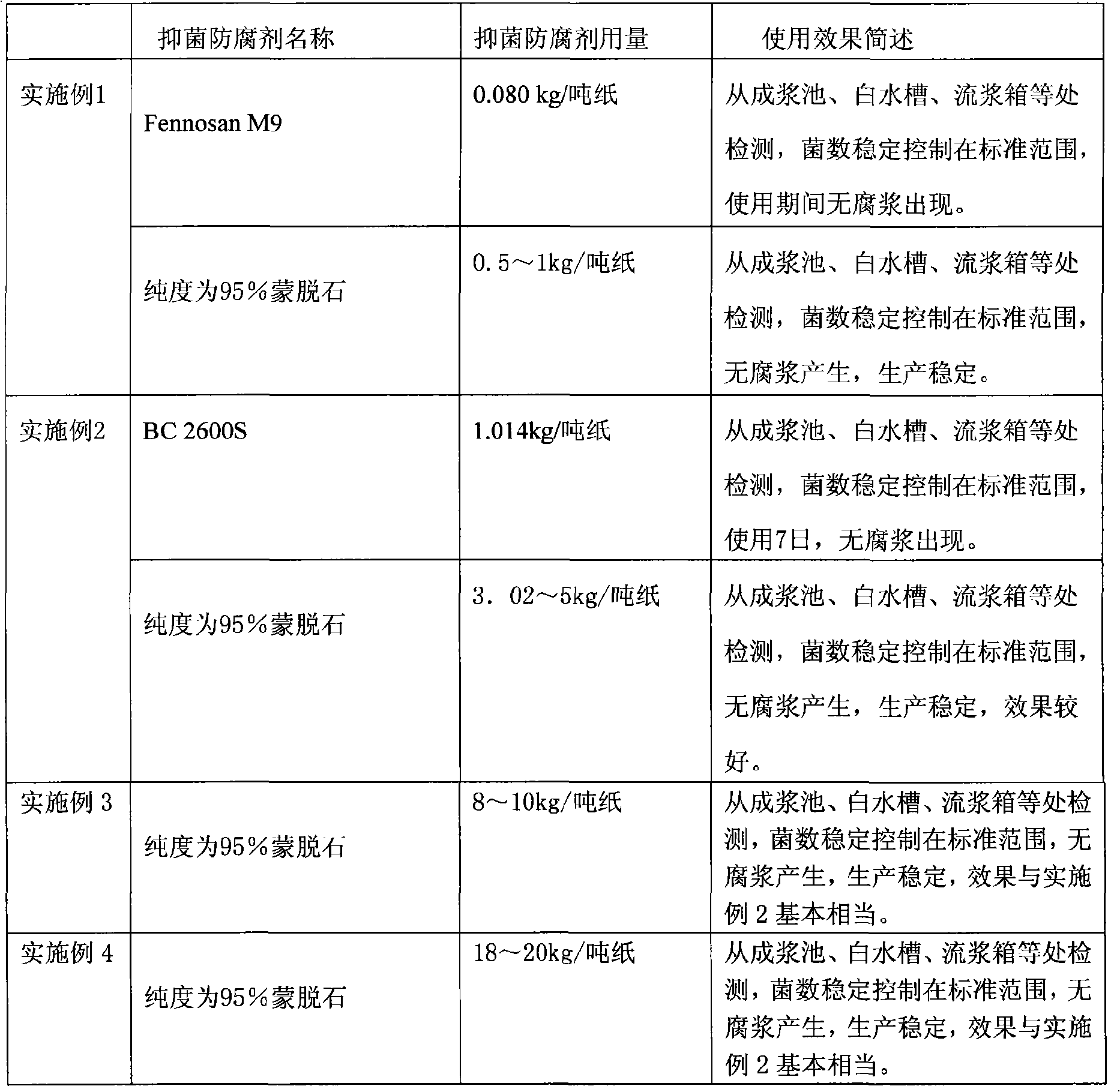

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

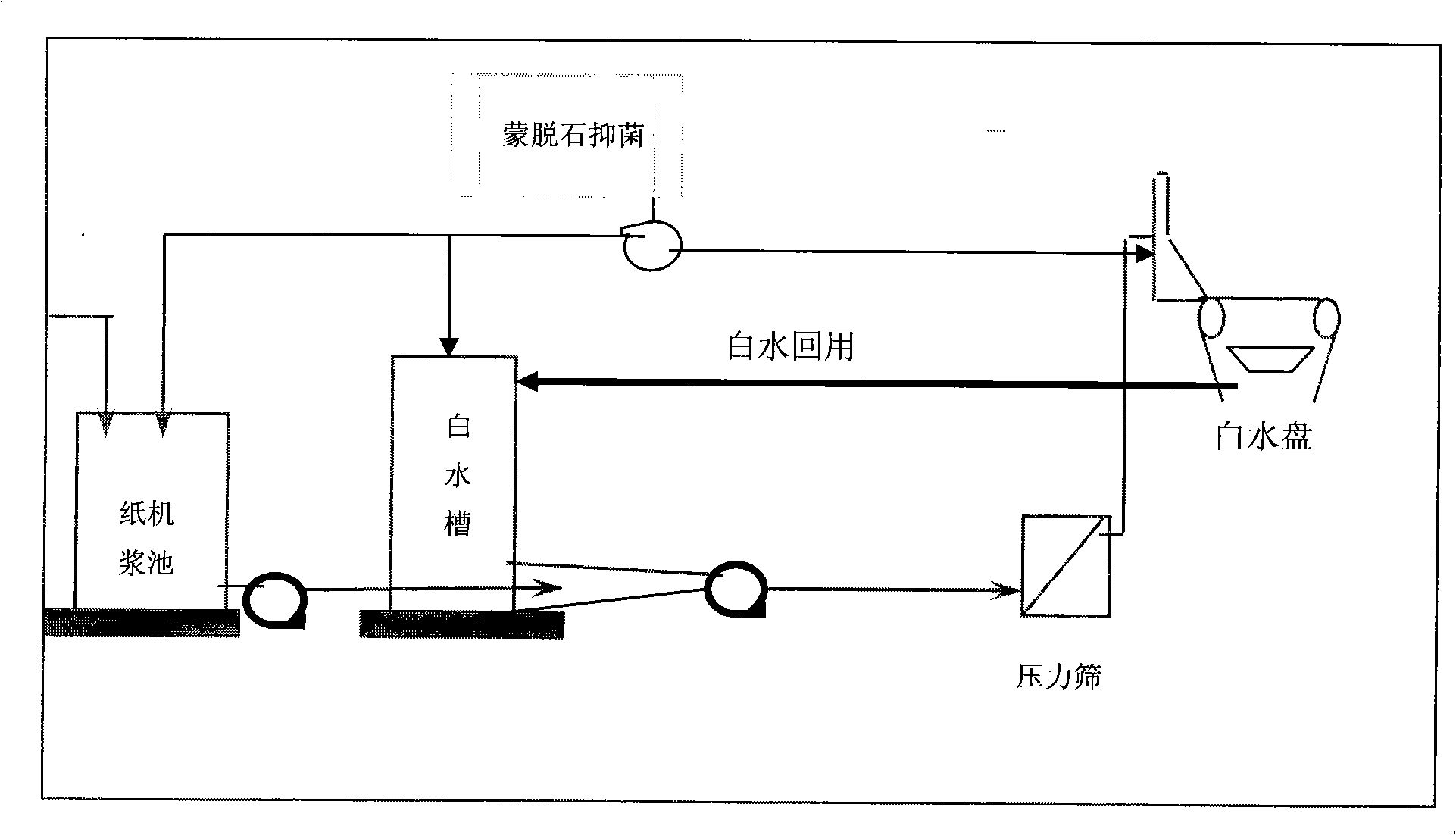

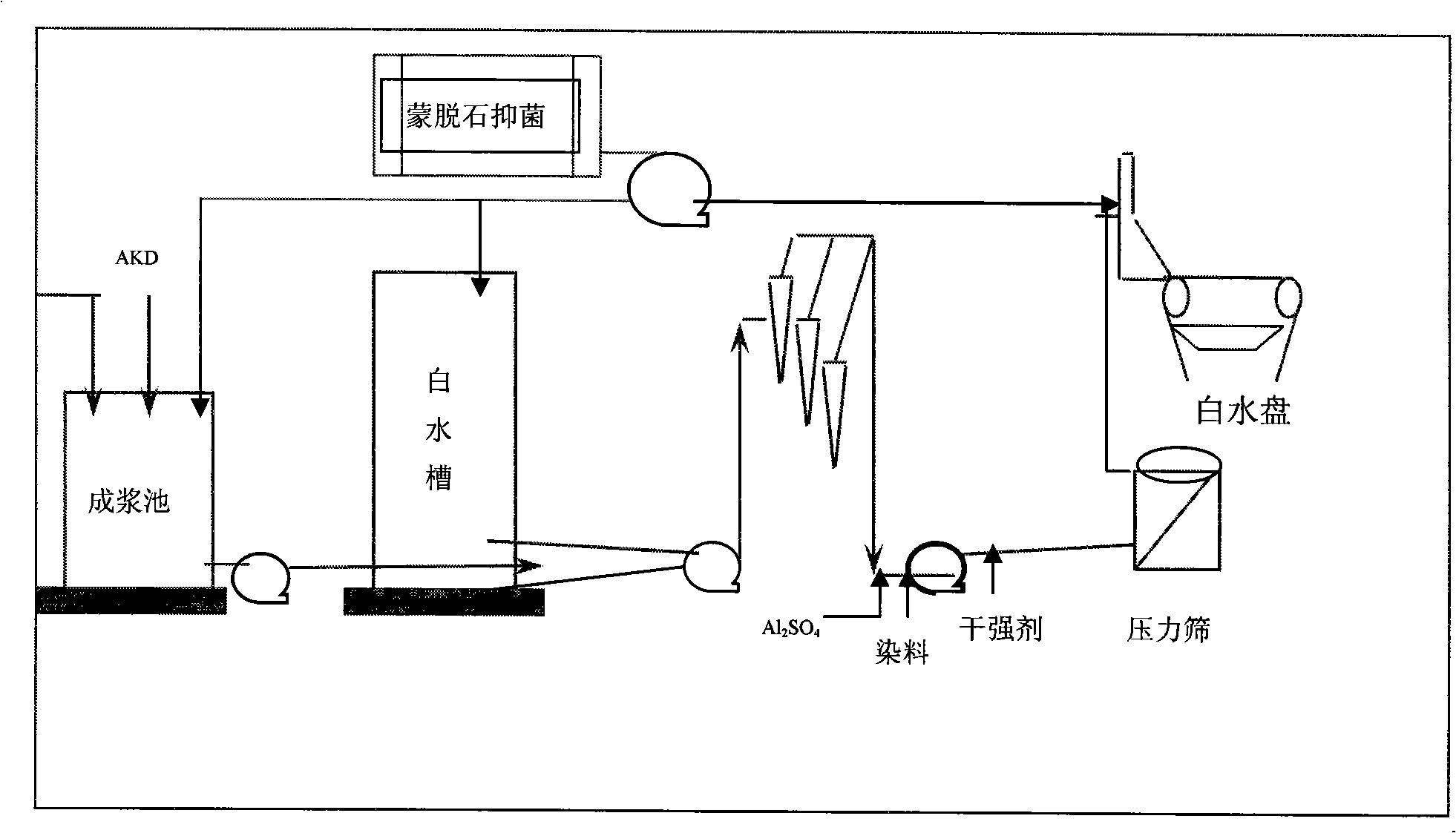

The invention discloses an application of the bacteriostatic and rotproof functions of turface to the paper-making technique. According to the standard that every ton of paper adopts 0.5 to 20 kilograms of turface with a purity quotient of 95 percent, the turface is directly added into a paper-making system. If the turface with a purity quotient less than 95 percent, the usage amount of turface is increased correspondingly. The optimized usage amount is 0.5 to 5 kilograms of turface per ton of paper. The good expanding performance and the dispersivity of the turface ensure that compositions inside the paper pulp is scattered evenly and microorganisms are scattered inside the paper pulp; the turface has good adsorptive action and can absorb most of the microorganisms which are adhered on the fibers and are discharged out of the system as the paper-making process; therefore, the concentration of the bacteria in the paper-making system is minimized, thereby achieving the bacteriostatic effect. Meanwhile, the turface can also absorb various paper-making additives, organic nutriments and fine fibers which are discharged out of the system as the paper sheet, thereby reducing the white water concentration and damaging the condition bacteria live by, achieving the bacteriostatic effect and reducing the possibility of forming slime pulp.

Description

Antibacterial and antiseptic application of montmorillonite in papermaking process technical field The invention belongs to the technical field of papermaking in light industry, and relates to the application of a mineral in the papermaking process, in particular to the application of montmorillonite in the antibacterial and anticorrosion of the papermaking process. Background technique The papermaking system of the papermaking process is rich in nutrients, and has a temperature and humidity suitable for the growth and reproduction of microorganisms, especially the neutral papermaking system is more suitable for the growth and reproduction of microorganisms. The wide use of various chemical additives for papermaking, such as starch, is more conducive to the growth and reproduction of microorganisms, so that viscous sludge will be formed on the inner wall surface of each tank, pulp inlet and circulation pipeline during the papermaking process. It is composed of microfibers,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H21/36D21H17/68

Inventor 张有连童筠窦圣范昕张金琴张怀猛姜键俞铁明

Owner ZHEJIANG RENHENG CHEM

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com