Hoisting method for framework of large tonnage pressing machine

A hoisting method and press technology, which is applied to presses, cranes, transportation and packaging, etc., to achieve the effects of ensuring safety, shortening the construction period, and saving hoisting problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

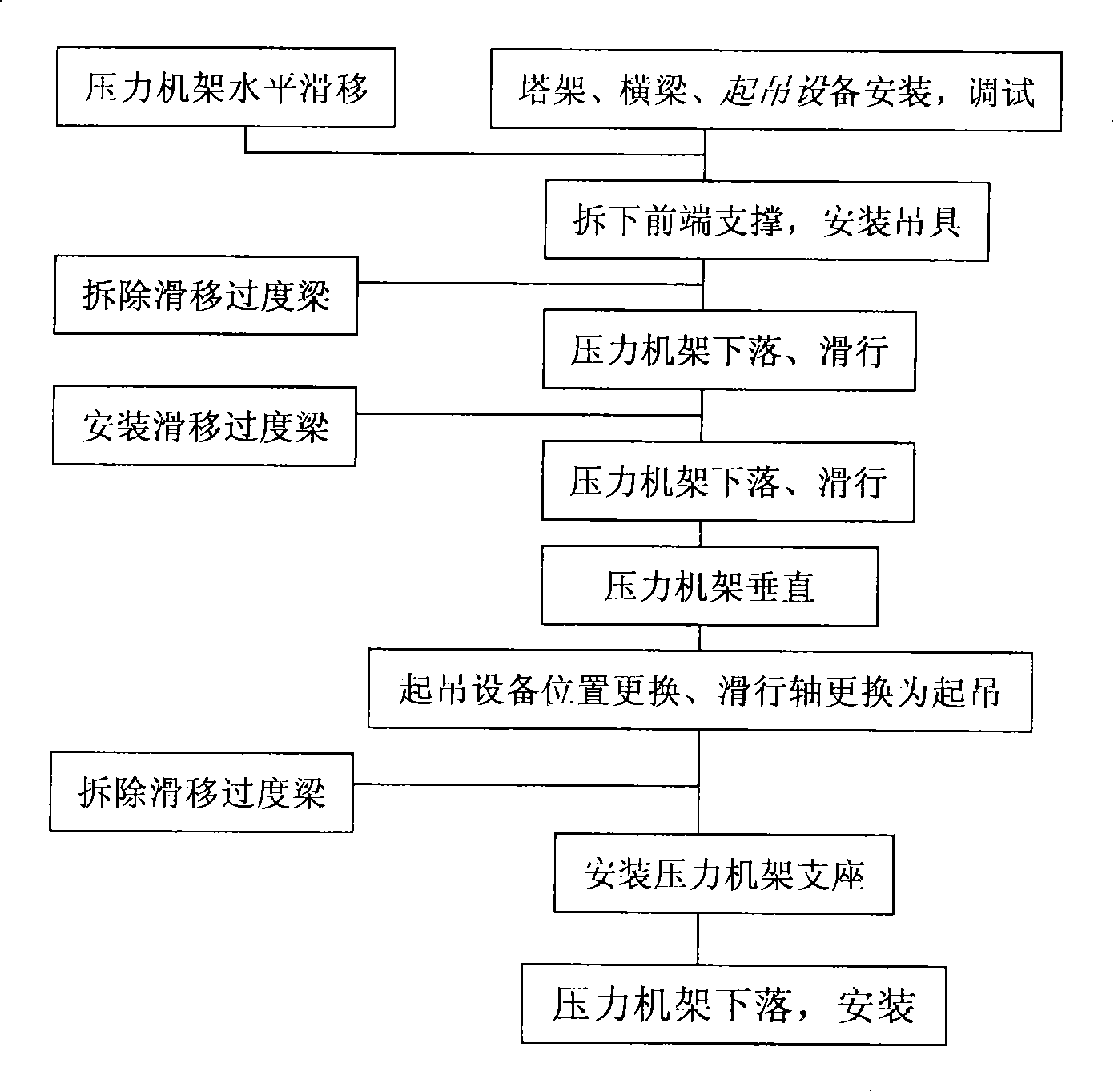

[0030] The hoisting method of the large-tonnage press frame described in this embodiment, according to figure 1 Follow the steps shown:

[0031] 1. Install towers, beams, lifting beams, lifting equipment, commissioning:

[0032] (1) Installing the tower: The tower body is composed of two sections. Before installation, it is assembled on the ground, and the two sections of the tower are formed in pairs. The upper beam of the tower is fixed on the tower, and then the tower is installed: Lift the tower to the base of the tower with a high-span crane, adjust the verticality of the tower through the plumb line and the surrounding temporary wind ropes, and after the verticality is adjusted, tighten the connecting bolts and fix the wind ropes;

[0033] (2) Install the crossbeam: Lift the crossbeam with a high-span crane, and then use bolts to connect and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com