Intelligentized regulation system of air-conditioner fin die

A technology for regulating systems and air-conditioning fins, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high technical requirements, troublesome, time-consuming and other problems of operators, so as to reduce consumption, reduce production costs, extend the The effect of the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

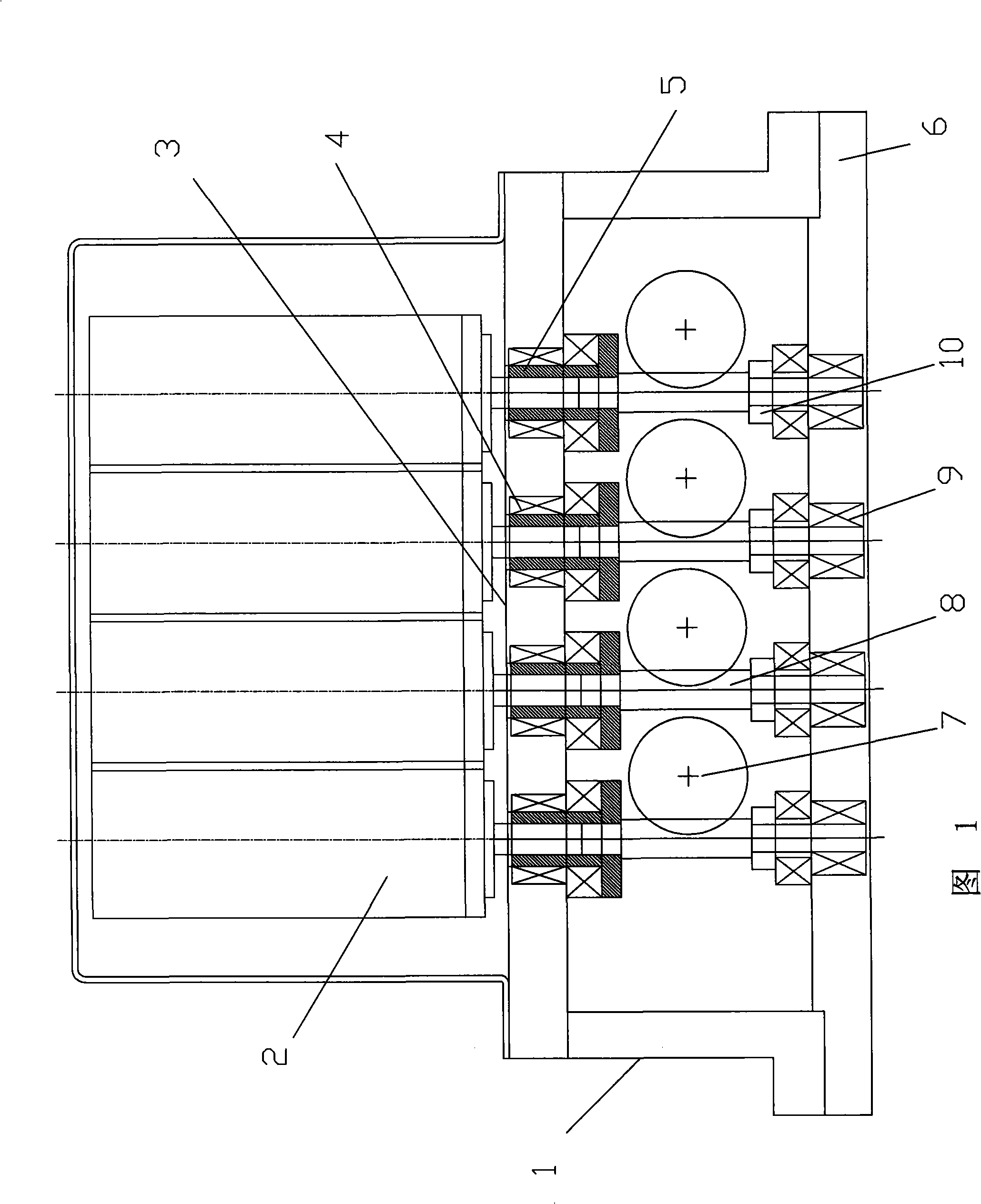

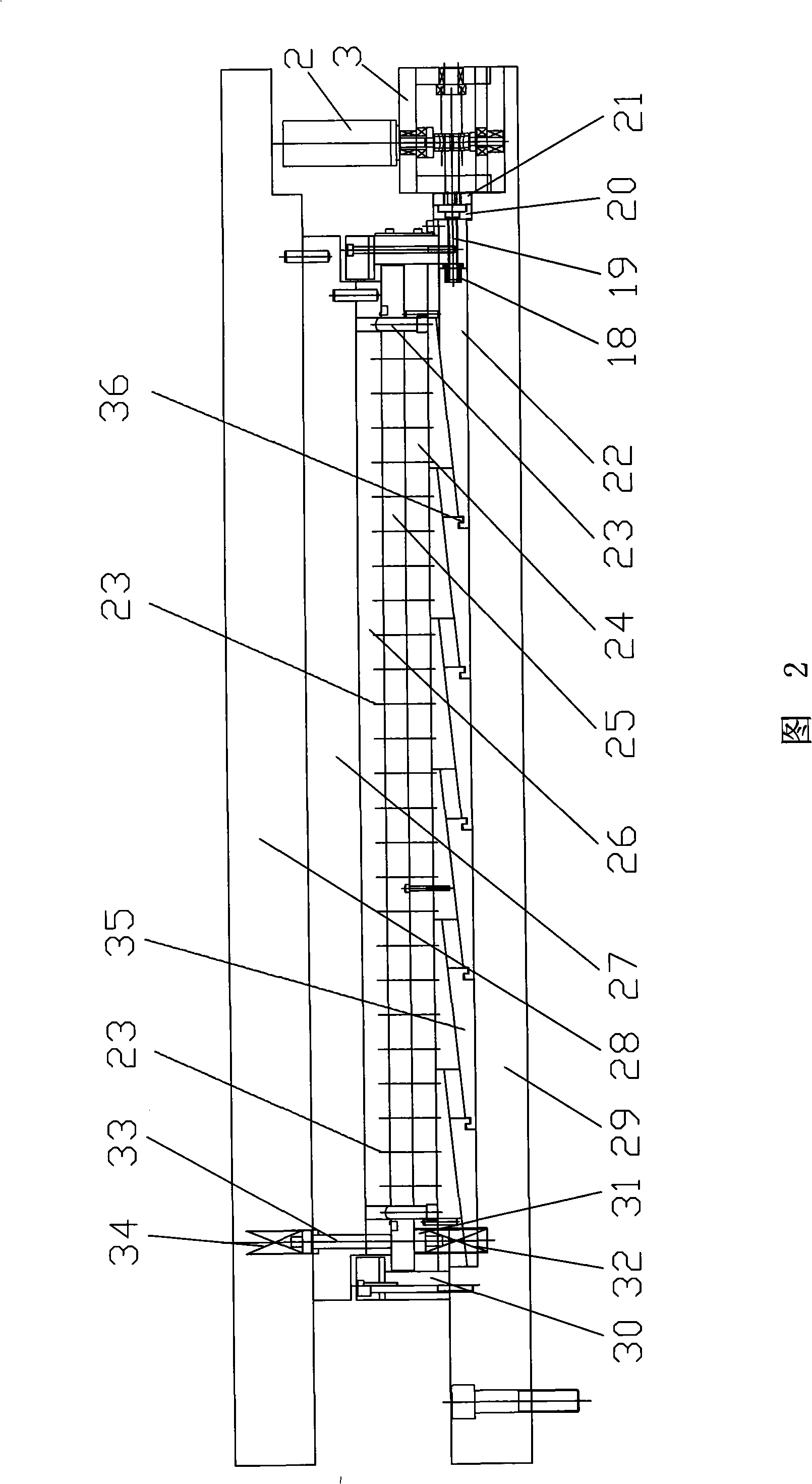

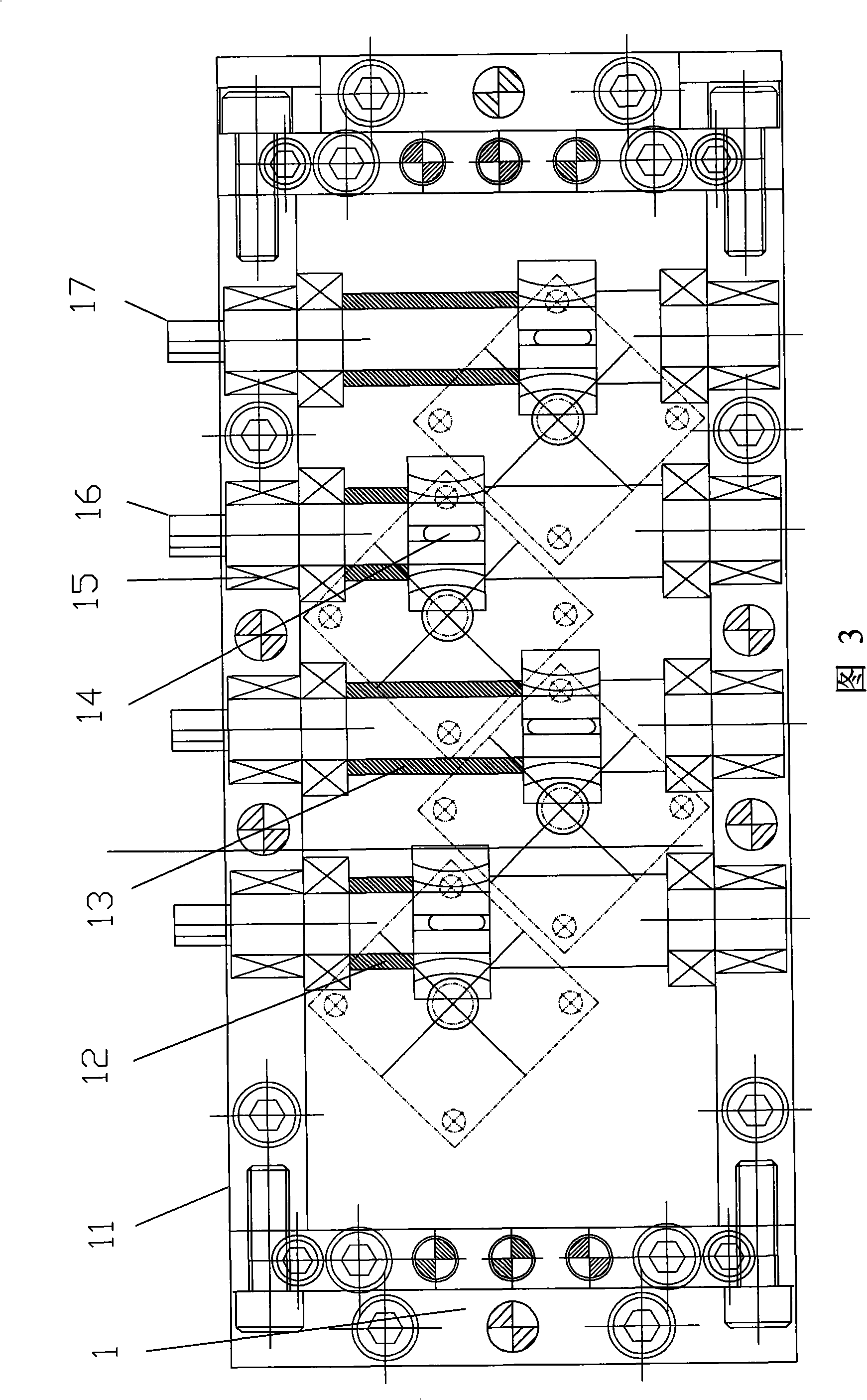

[0018] In the figure: 1. Left and right side panels, 2. Servo motor, 3. Cover plate, 4. Bearing, 5. Bushing, 6. Backing plate, 7. Turbine, 8. Worm, 9. Bearing, 10. Positioning sleeve, 11, front and rear side panels, 12, limit sleeve, 13, limit sleeve, 14, key, 15, bearing, 16, guide rod, 17, guide rod, 18, nut, 19, screw rod, 20, fixed block, 21, fixed block, 22, lower slider, 23, punch, 24, punch fixed plate, 25, unloading plate, 26, concave template, 27, backing plate, 28, upper template, 29, lower template, 30 , limit block, 31, unloading ejector pin, 32, spring, 33, feeding ejector pin, 34, spring, 35, upper slide block, 36, buckle.

[0019] As shown in the figure: several servo motors 2 are installed on the frame, the output end of each servo motor 2 is respectively connected to a reduction mechanism, and the output end of each reduction mechanism is respectively connected to a screw 19, and each screw 19 Cooperate with connecting nuts 18 respectively, and each nut 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com