Intelligent type motorcar chassis lacquer spraying arrangement

A kind of automobile chassis and intelligent technology, applied in the direction of surface coating liquid device, coating, etc., can solve the problems of unsafe, difficult working environment, etc., to eliminate unsafe hidden dangers, reduce labor intensity, and ensure the quality of painting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

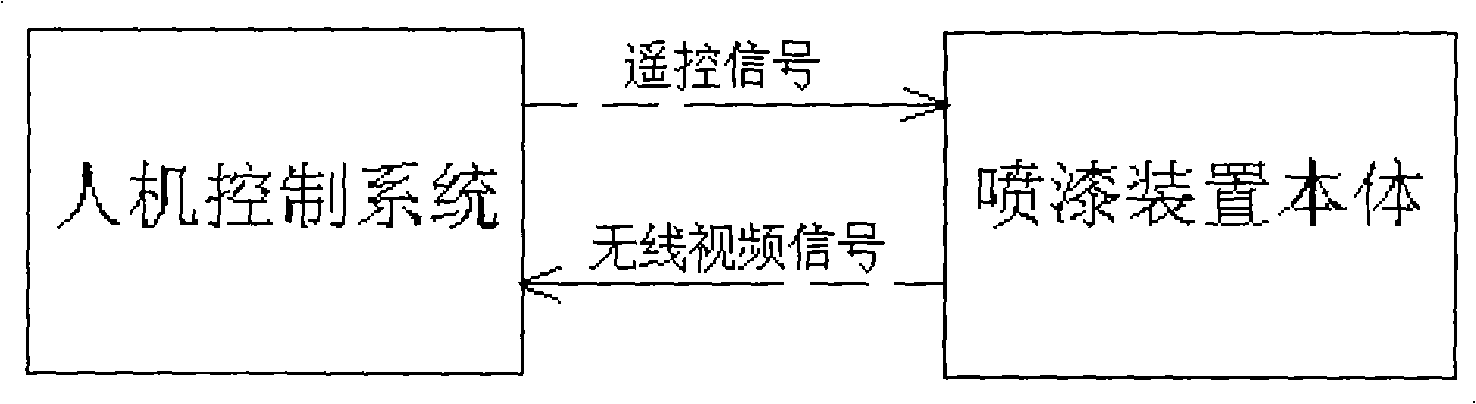

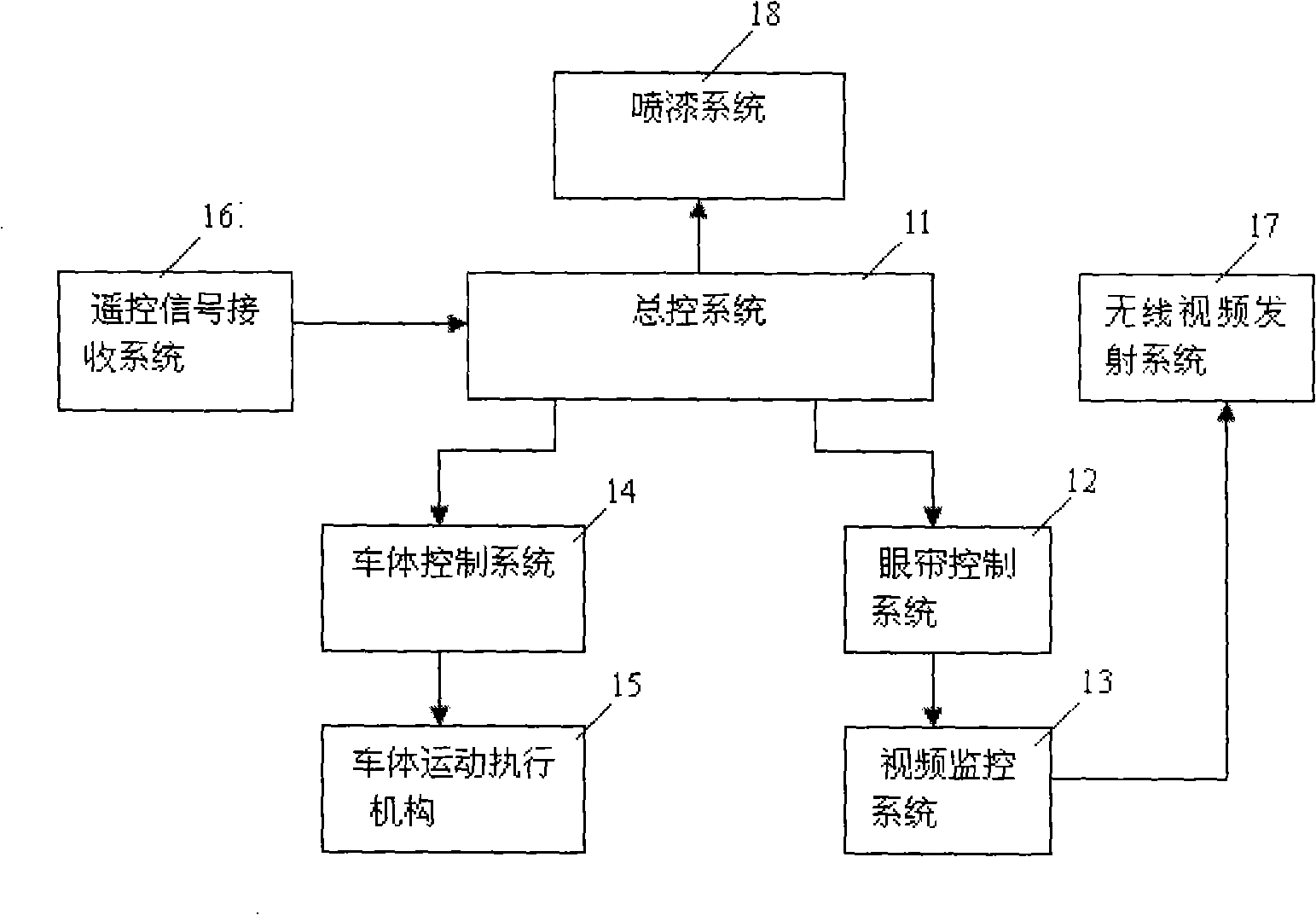

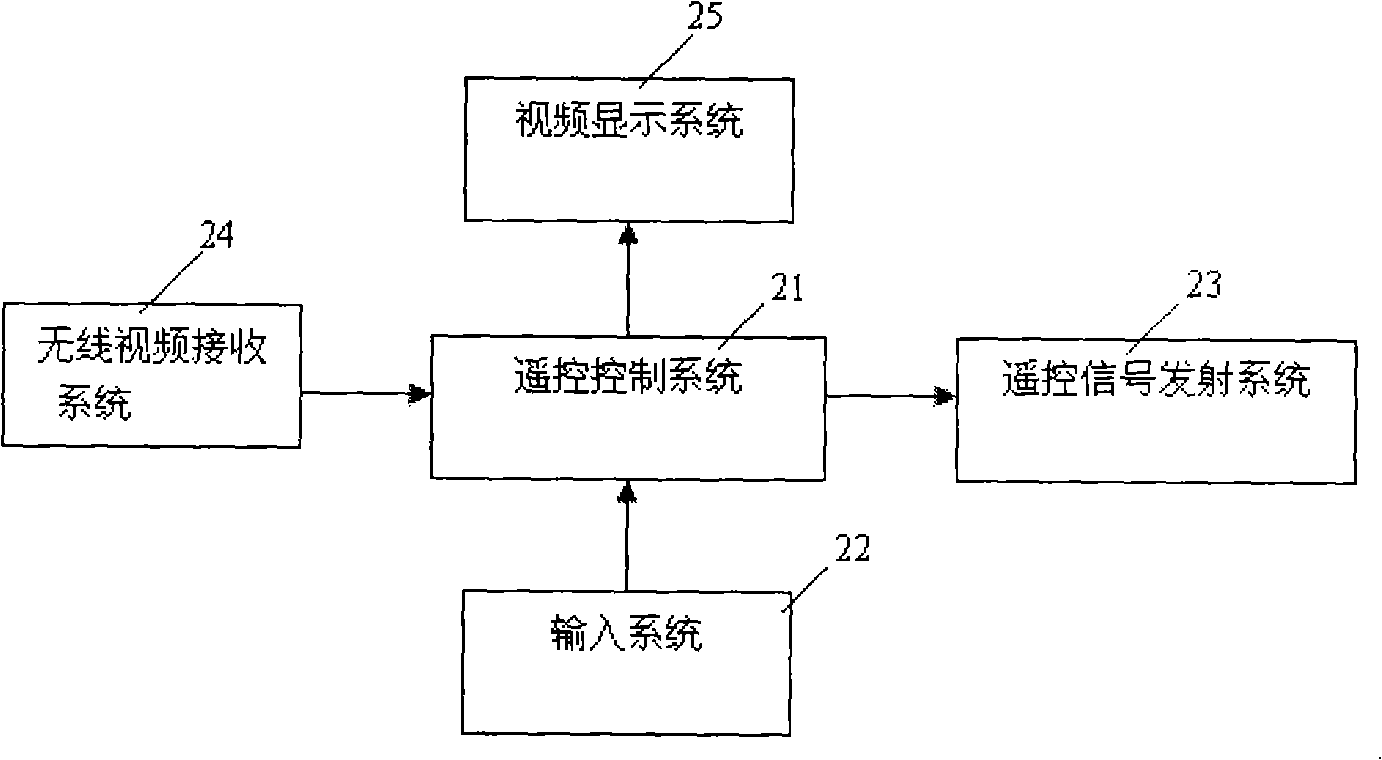

[0034] see figure 1 , a kind of intelligent automobile chassis paint spraying device of the present invention, is made up of two parts of painting device body, man-machine control system, wherein, paint spraying device body is made up of master control system 11, car body control system 14, car body motion actuator 15 , a remote control signal receiving system 16, a paint spraying system 18, an eyelid control system 12, a video monitoring system 13, and a wireless video transmitting module 17, see figure 2 ,in:

[0035] Master control system 11: It is the master control part of the main body part of the intelligent automobile chassis painting device. It receives instructions from the man-machine control part of the device through the remote control signal receiving system, and controls the car body control system according to the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com