Stapler

A stapler and sensor technology, which is applied to staple staple tools, staple tools, manufacturing tools, etc., can solve problems such as inability to bind paper, and achieve neat binding positions, stable binding, and good binding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

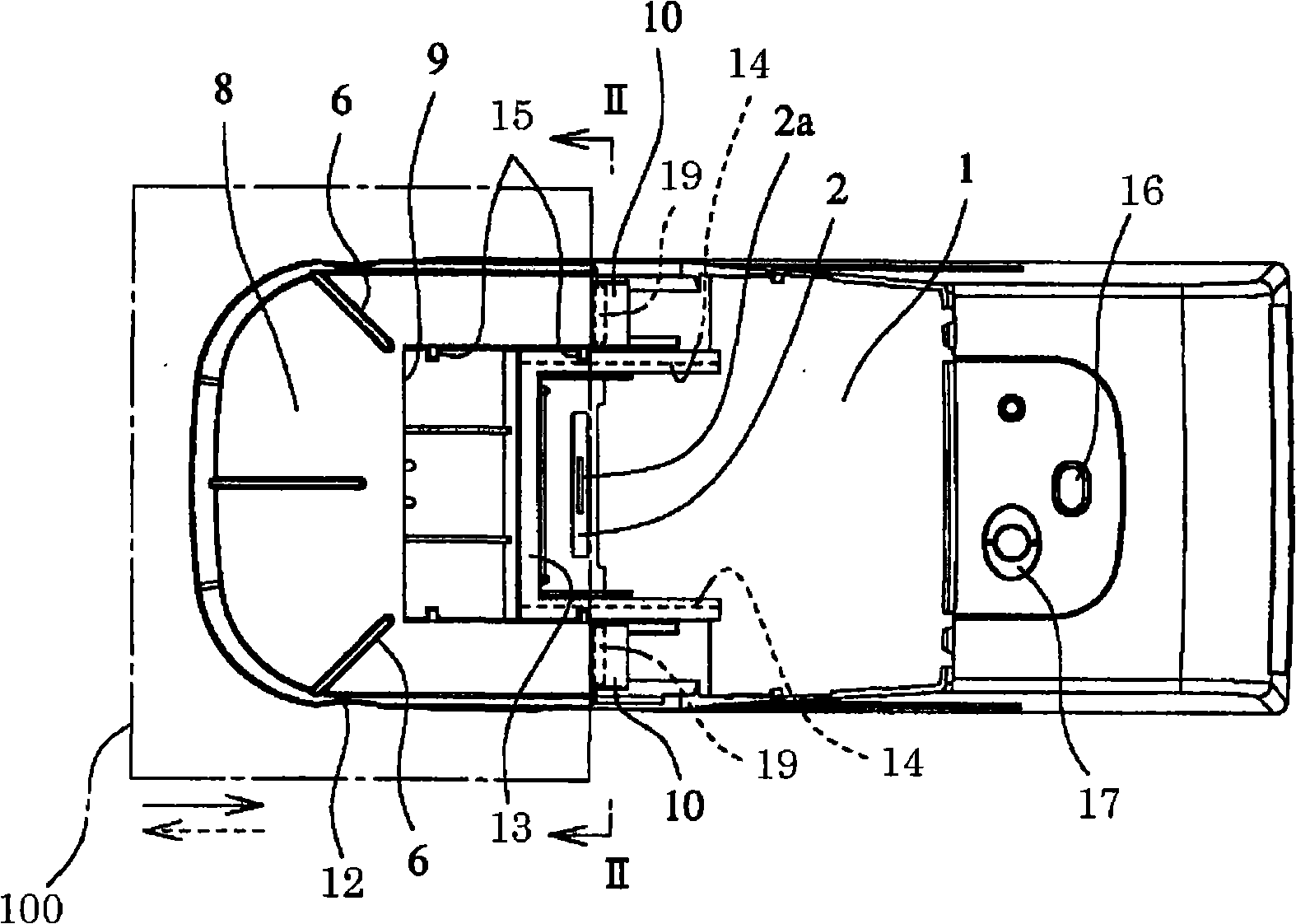

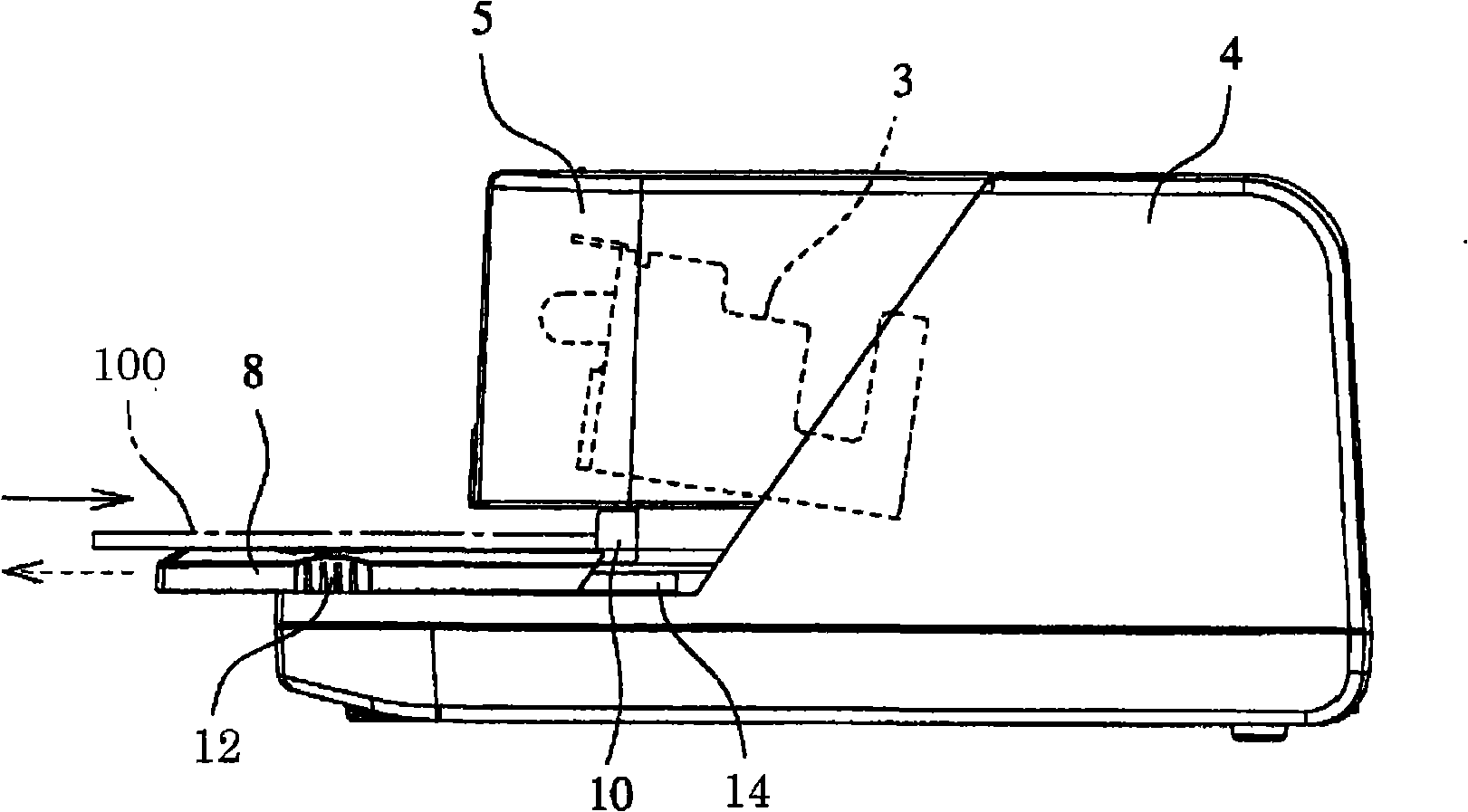

[0050] Such as Figure 1A , Figure 1B As shown, the electric stapler in Embodiment 1 includes a binding table 1 provided with a stapling component 2 ; The sheets 100 are inserted between the stapling member 2 and the staple driving unit 3 to be bound. The upper rear half of the binding table 1 and the output unit 3 are covered by covers 4 , 5 .

[0051] The staple driving unit 3 has a staple driving mechanism that drives a driving plate that drives staples. This driving mechanism is operated by an electric motor, and drives the leading staple in the driving unit 3 downward. The driven staple penetrates the paper 100 and is bent in contact with the binding groove 2 a of the binding member 2 to bind the paper 100 .

[0052] A movable stage 8 is provided on the front half of the binding table 1 . The movable stage 8 is a member on which paper 100 is placed, and its upper part has the same shape as that of the binding table 1 . A concave portion 9 is formed inside the movabl...

Embodiment 2

[0062] Figure 6A is a plan view of the electric stapler in the second embodiment, Figure 6B yes Figure 6A side view. Furthermore, the section VII-VII of FIG. 6 is shown in FIG. 7 . In the second embodiment, the same components as those in the first embodiment are assigned the same reference numerals, and descriptions thereof are omitted.

[0063] In the electric stapler of the second embodiment, a paper detection sensor 20 is provided to face the recessed portion 9 formed in the rear portion of the movable stage 8 . The paper detection sensor 20 is guided by the guide rail 18, which can slide in and out of the paper 100 in the insertion and withdrawal direction (front and back direction) of the paper 100 in such a way that it can enter and exit freely relative to the concave portion 9, wherein the guide rail 18 is provided on the binding member 2 having the binding groove 2a. The rear part is arranged on the top of the binding table 1, and extends a predetermined length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com