A stapler with a binding ruler

A stapler and ruler technology, applied in the direction of manufacturing tools, U-shaped nail tools, nailing tools, etc., can solve the problems of no scale, unequal distance, short binding baffle, etc., to solve the problem of ease of movement, Low production difficulty and accurate binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

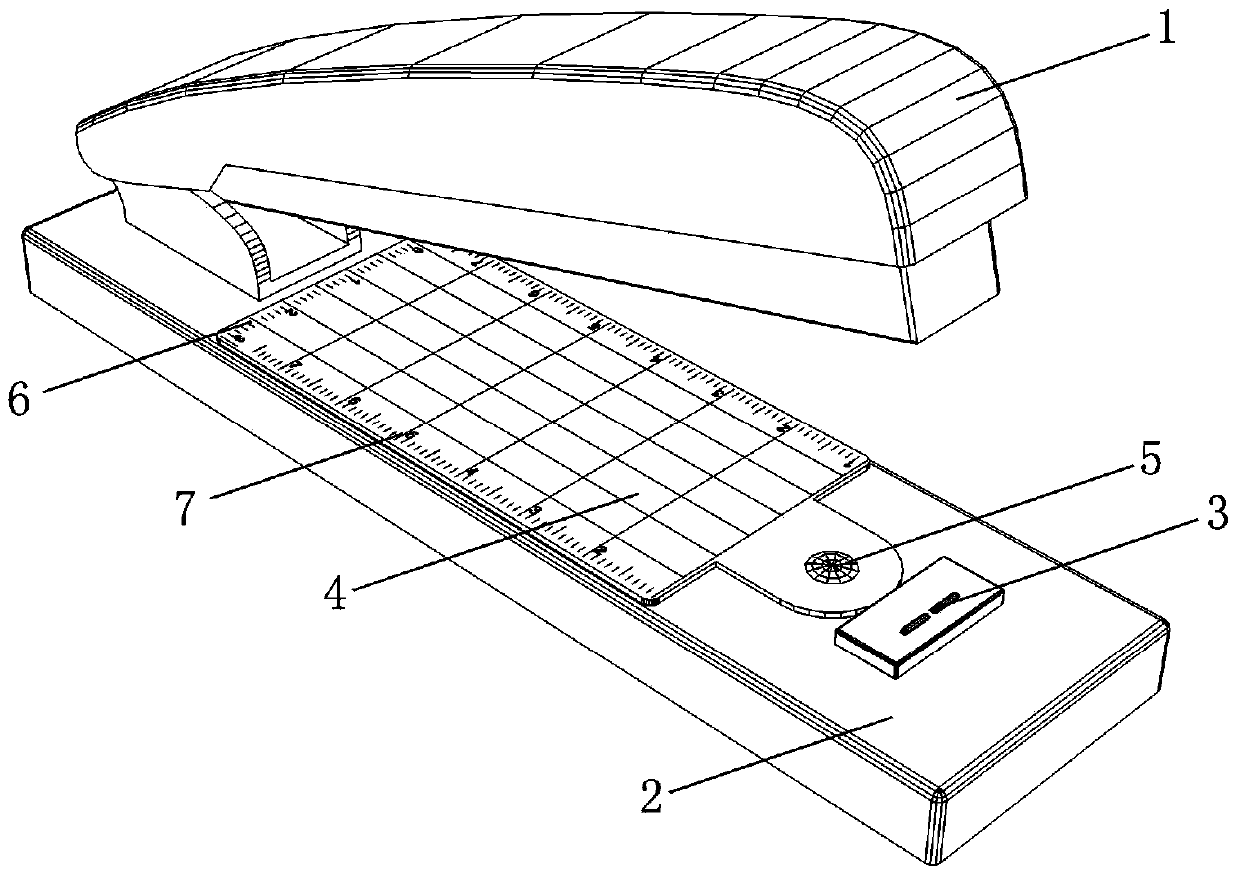

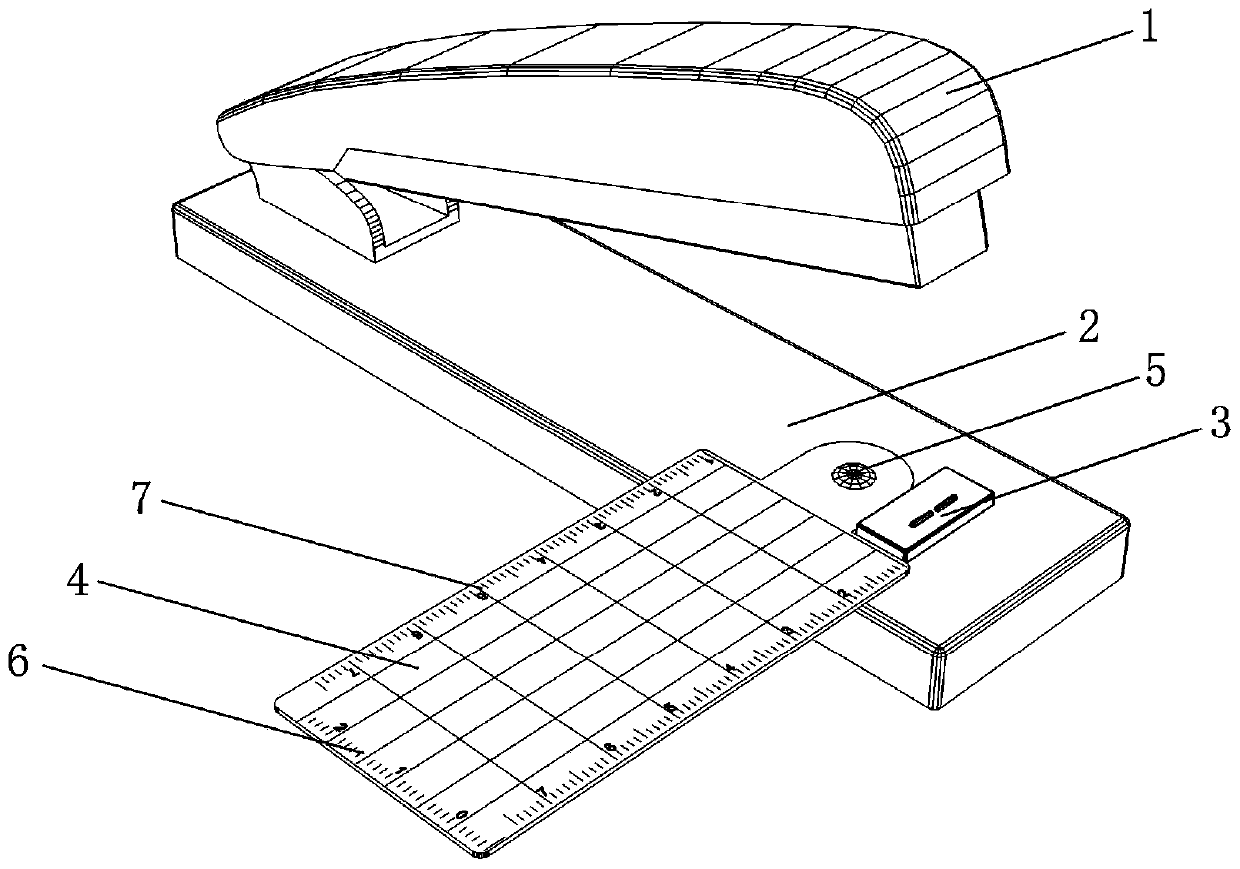

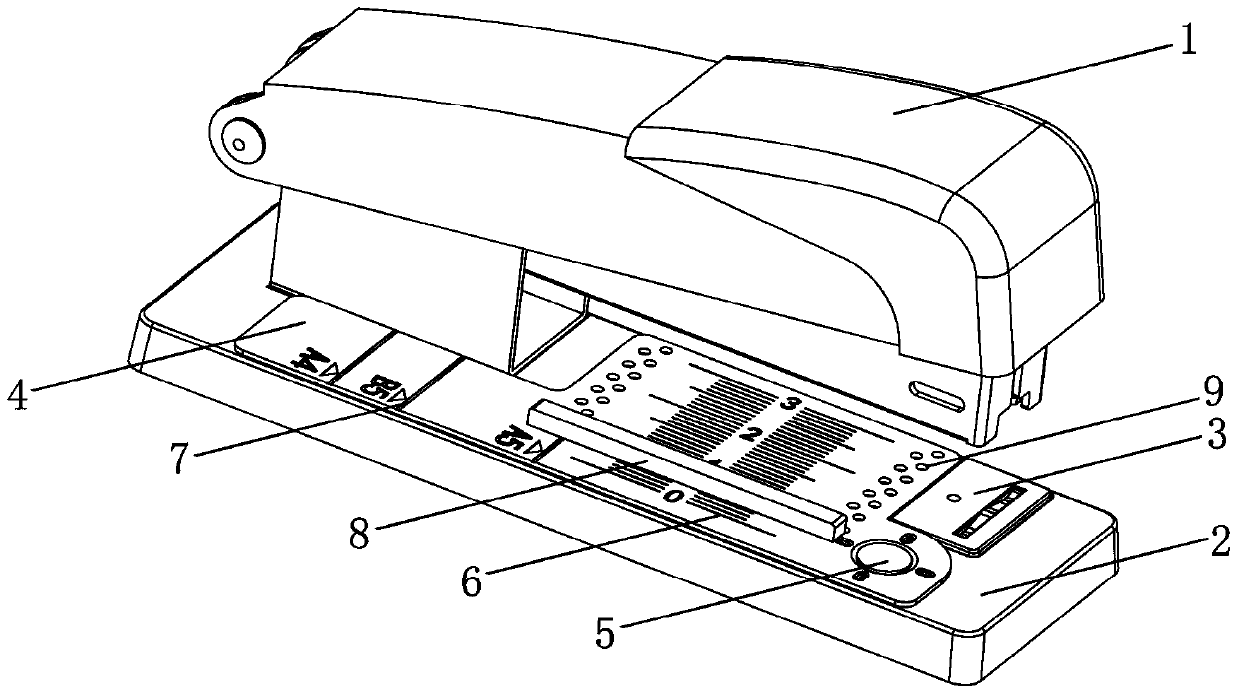

[0016] Control attached figure 1 , 2 , figure 1 is a perspective view of one of the embodiments of the present invention, figure 2 It is a three-dimensional view of the use state of one of the embodiments of the present invention, and it is the basic idea of the scale rotary stapler of the present invention. The stapler base 2 in the figure is equipped with a binding scale 4, and the binding scale 4 is a flat plate whose length is greater than the width of the base and whose width is less than or equal to the width of the base. The binding scale 4 is installed on the base 2 by the rotating shaft 5. When not in use, The binding scale 4 is stored in the base 2, and rotates 90 degrees along the rotating shaft 5 to one side of the base during use to form a binding scale 4 whose length is greater than the width of the base, providing a reference for the stapler to determine the binding position of the staple. This embodiment is the most basic embodiment of the design idea of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com